Digital twins building new engineering worlds in a digital ecosystem

Intelligent software systems enhance drilling engineers’ decision making with rapid visualizations, real-time well plan updates

By Stephen Whitfield, Associate Editor

The oil and gas industry is in the throes of a digital revolution that is already creating step changes in the efficiency of well planning and well construction. As part of that revolution, digital twins – software-based representations of physical assets – are increasingly becoming a key tool in the push to drive greater efficiencies in all stages of E&P.

Digital twins of production assets, like FPSOs and offshore supply vessels, are already commonplace, allowing operators to minimize downtime and maintenance costs. Lately, companies have also developed and continue to refine digital twins of the wellbore itself, generating efficiencies during both well planning and drilling.

“We need these digital platforms and these digital twins,” said Arnfinn Grøtte, Manager – Drilling and Wells Digitalization at Aker BP, adding that the need to better understand available data is driving a lot of the operator’s digital transformation efforts. “We need new architecture that will allow us to use the data we have, and these are the kinds of systems we’re building.”

Digital twins are already commonly being used to streamline the well design process and to serve a wide range of well construction functions, such as optimizing drilling parameters like rate of penetration (ROP) and weight on bit (WOB). Additionally, with their predictive capabilities, they alert operators to potential issues downhole like collisions or stuck pipe that could add nonproductive time (NPT) to a drilling operation.

Increasingly, the industry is also seeing open-source platforms aimed at easing the integration of data across multiple platforms. Such systems allow companies to more easily visualize a multitude of well construction scenarios and make better decisions.

“We’re really tying together the system from the perspectives of geoscience, planning and design, and execution and even production, so that we have a common and rapid understanding of the changes happening downhole,” said Olivier Germain, Digitalization Program Director at Halliburton Digital Solutions. “With these systems, we’re seeing much more integration across the sectors. The operator is not working on its own but is working with multiple suppliers to optimize the well’s design, so that not only do you know where to drill the well, but you also improve the execution of the drilling program and its outcome.”

Automated simulations help to analyze risks in well construction

One of Halliburton’s entries into the world of digital well planning is DecisionSpace 365, an umbrella name covering a line of cloud-based geoscience, production, reservoir and drilling applications. Two of these applications are Digital Well Program and Well Operations Monitor, both launched in 2019, which allow users to design a well plan, create a digital twin of the planned well and monitor activities against that plan.

To design a well using the Digital Well Program, two workflows are available: factory and interactive. The factory drilling workflow essentially uses the concept of the program template or archetype, requiring inputs on target and surface location, the well template to be used and confirmation about the subsurface data. The program will run automated simulations of the drill plan, including well trajectory analyses, geological prognoses, well integrity analyses, well completion analyses and estimated drilling time and costs.

If the system does not detect any issues with these variables, the user gets a green light. If issues are detected, the system will alert the user with either an orange or red light, depending on the severity of the issues detected, as well as provide analysis of the detected issues. As the user revises the well plan, the system will also run automated workflows using new engineering models and update the activity on the fly.

Under the interactive workflow, users can analyze the risk probabilities of various scenarios based on a wide range of different factors. For instance, if the user is unsure about how much WOB to apply, the system can run concurrent simulations of the well plan using different WOB levels. A green-orange-red indication is still provided for the entire well plan when using this workflow.

“With the factory drilling mode, essentially you press a button, and it automatically works for you,’” Mr Germain said. “But in cases where you have a lot of unknowns and uncertainty, you need a more iterative process. Sometimes during the field planning stage, you don’t have much information – you just have rough ideas.

“The system models the uncertainties and does some scenario analyses. There can be different variations where, for instance, you run your simulation based on possible geo-pressures. This workflow is more like a scenario management, where you can try and refine different options to see which one works better as you acquire more data.”

The factory drilling option applies to many brownfields with standardized operations worldwide, Mr Germain said, while the interactive workflow is typically used in greener field developments where there may be greater uncertainty regarding subsurface data.

“Every user is different, every company is different, every well is different – that was the tricky part in developing this system,” he explained. “How much do you allow the user to manage, and how much do you put in the prescribed workflow? We’ve hit a balance where you can utilize a minimal workflow, but in cases where a customer wants more control over the planning, it can still incorporate their policies and their cases. It leaves room and, more importantly, time for the user to do some of their own concepts in the design.”

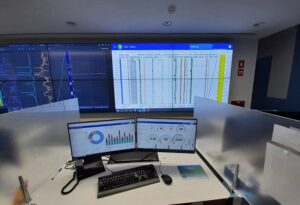

After the well is designed in the Digital Well Program, the Well Operations Monitor creates a digital twin of well operations, which enables users to monitor well activities against the well plan in real time. Used during drilling, this application provides advisory alerts on potential hazards that may increase NPT. Further, it records any adjustments made to the well plan during drilling and runs revised engineering models to determine what, if any, changes need to be made to the drilling program – for instance, if ROP or WOB need to be increased in a particular section of the well to achieve optimization.

“We’re taking repetitive workflows and streamlining them,” Mr Germain said. “We’re making sure everybody’s aware of what is happening and making sure engineers are not using obsolete information to design or drill their wells. That’s a game changer and a big time saver.”

Optimizing field development

Aker BP was one of the first companies to adopt Halliburton’s Digital Well Program in 2019, and the applications’ automated workflows have become a key component of the operator’s efforts to improve the well design process for its wells.

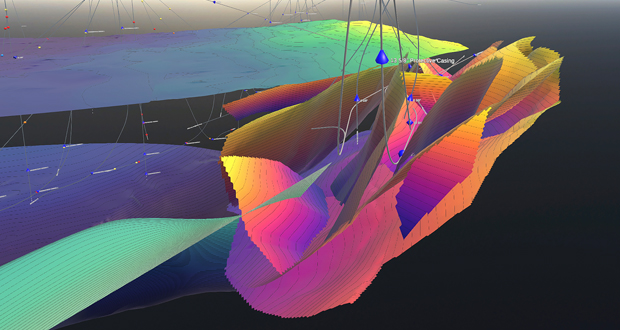

In particular, the company’s drilling engineers now have much better understanding of their data by using 3D visualization, versus the old way of using spreadsheets to view and process data.

“The digital twins help us understand all the subsurface data that we use to actually do the specific designs, and part of the challenge is being able to understand any changes in interpretation,” Mr Grøtte said. “When it comes to the subsurface data set, there’s always some uncertainty – it’s very rare that you have perfect logs where the formation changes are 100% clear. By using the digital twin, you’re actually representing these different formations in layers, which makes it much easier for the engineers to understand when the data changes, how those changes affect the well designs, where we put the casings in, etc. We can contextualize the subsurface.”

The next step in Aker BP’s digital well planning efforts is a new cloud application, Field Development Planning (FDP), that converts the manual process of collating field development data into an automated digital system. The FDP application can be used to model multiple wellbores within a single field. If the operator plans to drill multiple wells from the same asset, or within the same field, it can model the optimal trajectories of each well to reach the desired target.

The FDP application, which Aker BP jointly developed with Halliburton, also provides alternative field development plans modeling different well trajectories with different risk profiles. These types of predictive capabilities allow the operator to spend more time focusing on removing or minimizing the risks associated with challenging wells, Mr Grøtte said.

“The wells are getting more and more complex. We need to free up engineers’ time to focus on the risks and make sure that we drill successfully to total depth. With the FDP, we’re essentially putting thousands of Excel spreadsheets and reports all into one digital twin,” he said. “Normally, when we do an offset analysis, we’re probably spending weeks gathering data and trying to organize it. In the past it was all in Excel. But now you can easily look at 20 nearby wells – all the events, all the risks, everything that happened when we drilled those wells. You can make a data-driven decision on what is the likelihood for something to happen and you can back it up with actual analysis generated very quickly.”

Aker BP launched the FDP application in Q3 2023, after three years of development and testing. It will be integrated with the Digital Well Program so data can be transported automatically, eliminating the need to repeat data entry.

In addition to its work on field development, Aker BP also recently announced a partnership with Halliburton, Microsoft and SLB on the construction of a data mesh platform aiming to enable multi-vender interoperability on geological modeling and well planning. The system will be based on the OSDU data platform, an open-source, cross-company, cloud-native reference architecture that outlines standards for data management in oil and gas operations.

By being able to convert data into standardized formats, different operators and third-party vendors can run data analytics on their own software without needing to rebuild any code. For example, a service company can utilize the data generated in the FDP platform to run analysis within its own existing platform, instead of having to build a modified software that’s integrated with FDP. The results can then be shared through standard and interoperable application programming interfaces (APIs).

The type of data being targeted include subsurface data, well logs, well trajectories and fluid/rock properties.

“Really, what this data mesh is doing is giving every vendor the possibility to build integrations into an app and share data without having to change their software to a new standard,” Mr Grøtte said. “That’s always part of the challenge when you’re adding third-party software – having to go back to change the core parts of the software instead of just adding some existing information to the data that exists.”

The platform is scheduled for release in 2024.

Predictive analytics to improve efficiency

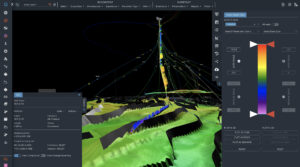

WellsX, a company founded in 2017 that provides digital solutions for drilling operations, is moving in the digital space with the development of ECO (Engineering, Control and Optimization). It is platform that integrates applied physics modeling with the Internet of Things to predict downhole hazards in real time.

The ECO system contains three components. The drilling section plan component allows users to estimate the expected mechanical and hydraulic loads in the well for all types of process operations prior to the start of well construction. The calculations generated by the software take into account drillstring parameters, friction coefficients, rheology and the density of the drilling fluid. The drilling roadmap component organizes various parameters – ROP, WOB, estimated flow rates, section lengths, as well as the mechanical and hydraulic load estimates from the drilling section plan – for each planned interval. In the bit hydraulics component, users can select the bit configuration that will maximize the bit impact force on the bottomhole.

Once analyses is performed through these modules, the software builds a digital twin of the wellbore. By using surface and downhole sensor measurements – on drillstring parameters; mud density, rheology and temperature; drilling fluid; the well profile; and friction factors – the twin is always calibrated to the current state of the well. These parameters are visualized on a single interface, helping the driller and other personnel ensure they stay within the corridors established in the well plan.

The software also provides predictive trend deviation analysis, integrated with hydromechanical analysis, to predict fluid gains and losses, pipe-sticking mechanisms, cleanup problems and washouts during well construction. Users are alerted to potential issues so they can decide whether to take mitigating actions.

“ECO provides flexibility to configure the system per client needs, to function either in supervisory or fully automated modes. In both scenarios, actionable insights are delivered to decision makers in a timely fashion,” said Khaydar Valiullin, Co-Founder and CEO of WellsX.

He also described the platform as self-learning – effectively, each well drilled becomes an additional data point. Users can replay the drilled well data with parallel real-time calculation of the mechanical and hydraulic loads, and they can analyze well logs to clarify lithological information of the reservoir. When the user plans future wells in the same field, or in different fields with similar geologies, the system will leverage that previous data to inform the design of new wells.

“The more we utilize the system, the more useful it becomes,” Dr Valiullin said. “Even if you don’t have offset data, the digital twin is running in the background so you’ll have examples of previous exploration drilling to give you a better idea of what you’re doing.”

The technology has been in operation since 2019 for several operators and drillers working in Eastern Europe, including Hungary, Croatia and Serbia.

It has also been deployed in the Volga-Ural region of Russia by an operator who sought to optimize well construction time for onshore wells in mature brownfields. During drilling, the ECO system’s predictive analytics tools alerted personnel to emerging hazards related to wellbore integrity and open-hole quality, such as stuck pipe, wash-outs and twist-offs. This capability enabled continual updating and optimization of the drilling plan after encountering potential hazards.

The operator saw a 16% reduction in average construction time for directional wells drilled in the Volga-Ural region, as well as a 20% reduction in sidetrack wells, according to Dr Valiullin. He attributed a major part of the time savings to off-bottom activity, as automated analyses of the drilling plan revealed that up to 30% of the time spent conducting off-bottom activity in the drilling plan was NPT.

While WellsX has had limited engagement in the North American market so far, it now has plans to participate in a geothermal project in South Texas, Dr Valiullin added.

Last year, ECO was approved for deployment by a major national oil company in the Middle East after successful onshore and offshore implementation. In June, WellsX also announced a joint venture agreement to provide its technology for its clients in the Middle East. DC