Complex well construction challenges require collaborative focus

Pat York, global director of well engineering and project management for Weatherford, speaks with Drilling Contractor associate editor Katherine Scott about the need for service companies and operators to collaborate earlier in the well construction process in order to address complex challenges.

By Pat York, Weatherford

Well engineering and project management services are providing a powerful collaborative interface with operators for exploring, designing and implementing integrated well construction solutions. Drilling exploration and development wells can present complex overlapping problems that overwhelm the discrete, technology-oriented methods that typify the drilling process. This traditional approach is often unable to encompass a scope of challenges that range from concerns about meeting AFE targets and complying with regulations to mitigating risk.

Instead, the solution is being found in an engineering and project management approach focused on the operator’s end objective of constructing an optimal, high-integrity, on-target wellbore.

The process starts with concept development by the service company using the operator’s basis of design to identify and examine new options. In a collaborative environment, operator and service company experts refine the concept to produce a fully engineered well plan, and then execute it.

The step-by-step process involves pre-engineering, project assessment, identification of resources, creation of a project plan, a detailed engineering study, and implementation of the plan at the wellsite. Project management serves a pivotal role that integrates various technology solutions and streamline interfaces between clients, multiple product lines, operations and suppliers.

The engineering and project management service approach has evolved with the growing complexity of well construction and the corresponding jump in sophisticated and often overlapping non-traditional technologies and methods. Applied on a global basis in well sections, wells and fields, the approach is successfully addressing significant challenges to wellbore construction.

A recent well in an ongoing project offshore South America exemplifies the approach. Successfully applied in its first application, the well plan developed through the process is providing a new path forward for developing the difficult and costly field.

A significant number of prior wells using conventional well construction methods had been unsuccessful. At issue were depleted zones that commonly occurred when drilling the main boreholes to initialize sidetracks. Over an eight-year period, attempted sidetracks had experienced as much as 281 days of NPT. Some of those wells cost more than $85 million each, were non-productive and had 100% NPT.

A collaborative well engineering approach with the operator was engaged to find new options for the well construction conundrum. The executed well design successfully mitigated the issues and met all well objectives by combining managed pressure drilling (MPD) and reaming with casing (RwC) technology to overcome the unstable and underpressured zones.

A collaborative process

Central to the success of such an undertaking is a collaborative emphasis that builds a detailed understanding of well construction objectives and challenges. Operator and service company experts work in teams through phases of exploration (i.e., analyzing of the well’s challenges), engineering and execution to ensure that options are thoroughly examined and solutions fully vetted.

The project exploration phase begins with understanding all the challenges from the operator’s perspective. It is important to know how they have interpreted the data to arrive at their basis of design and their expectations in drilling the well.

On the basis of this information, well engineering service company experts look at alternatives from their perspective. A set of technical solutions and roadmaps are developed to describe various options. These scenarios are examined and challenged in collaboration with operator engineers to produce a set of vetted well design alternative concepts.

Engineering the concepts

These concepts are turned into a workable plan through upfront engineering that integrates well construction technologies and best drilling practices to most effectively deliver the well objectives while addressing its challenges.

Combining upfront engineering with the best-matched well construction technical solutions achieves the level of risk mitigation and economic viability needed to ensure operational success in difficult applications.

The engineering phase applies industry-accepted engineering best practices and leverages internal synergies and global expertise to design an optimized well plan.

It assigns the risk associated with applying various technologies, delivers multiple options across various hole sections, creates the front-end engineering design (FEED) study, and provides recommendations for the well design.

The well engineering begins with collecting a more detailed data set and concludes with the FEED study from which the well can be drilled. Continual collaboration is essential to the process. The detailed engineering analysis on proposed technical solutions requires a high level of communication that is facilitated by similar disciplines with complementary skills sets and capabilities. This parallel team makeup not only ensures that the respective experts can talk collegially with one another, it also brings a critical mix of knowledge and experience.

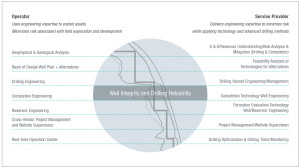

In this mix, the operator’s engineering strengths are typically geared to exploiting assets and minimizing exploration and development risks while the service company’s engineering expertise is aimed at minimizing risk while applying technology and advanced drilling methods. The two perspectives contribute to an effective engineering team for vigorously developing well construction solutions.

For example, in geophysical and geological activities, the operator’s analysis strengths are complemented by service company expertise focused on risk analysis and mitigation during the engineering and execution of the drilling and completion technical solution application engineering and operations. Additionally, in practice, the operator is engaged in cross-vendor integration and project management while the service company is tasked with technical solution project management.

Executing the plan

With the finalization of the engineering studies for each technology solution, the FEED study is prepared and the project moves to the field and the execution phase.

The transition at this step is particularly important. Plans developed in the engineering phase must be fully reviewed, understood and accepted by all of the operations teams (operators, drilling contractors and service providers) for the execution to be successful. To ensure this level of communication, operations engineers are typically involved in the engineering phase. Their engagement helps refine the well plan(s) and confirms it is fully optimized and executable with the operational risks minimized.

On the rig, training is conducted so that safety and operational efficiency are optimized while minimizing operational risks and the plan can be precisely executed. While a best practice in any application, the step has added importance with the introduction of new procedures and methods to standard rig operations.

The end game

From the beginning, well planning has one chief objective – construction of a high-integrity wellbore according to design. Incorporating service company engineering and project management in the process, from concept to execution, introduces new options for achieving that objective. These integrated technical solutions are successfully mitigating long-standing operational and economic well construction challenges.