Preventing lost circulation, instability offshore Malaysia

By Stephen Whitfield, Associate Editor

From an operator’s perspective, minimizing downhole losses while maintaining wellbore stability is one of the biggest challenges to successfully drilling an extended-reach well. Michael Yao, Senior Rock Mechanics Advisor at Hess, noted that extended laterals tend to have more breakouts than vertical or less deviated wells. This means a higher mud weight is often required to keep the wellbore stable.

Equivalent circulating density (ECD) is also typically higher. Moreover, there is a greater uncertainty in how the cuttings transport will behave, which can make hole cleaning more difficult.

If ECD, mud weight and hole cleaning are not managed properly, the operator runs the greater risk of wellbore instability, borehole collapse and lost circulation, all of which can increase the potential for the well to miss its target depth and to add significant costs to the drilling program.

“If you’re drilling a less deviated well, the drilling margin is typically wide. We have much more freedom to navigate mud weight and ECD between the pore pressure and the fracture gradient. It’s like driving in light traffic,” Dr Yao said, noting that drilling an extended-reach well is more akin to driving in a traffic jam. “Hole cleaning becomes more challenging, and the difference between the ECD and mud weight is much larger due to the hydraulics of these wells. There are much more challenging conditions to maneuvering the mud weight and ECD.”

Further, addressing the dual challenges of lost circulation and wellbore instability in extended-reach wells requires a holistic approach to strengthening the wellbore if the formation is depleted, he said. This has to be a collaborative effort among the operator’s drilling engineers, subject matter experts and rig site teams, as well as the service companies.

Dr Yao highlighted one such effort on a shallow gas field offshore Malaysia at an IADC Drilling Engineers Committee Technology Forum in November. In its most recent extended-reach well in the formation, the company had experienced lost circulation in the reservoir section, which showed unexpected depletion from production, and well startup was delayed.

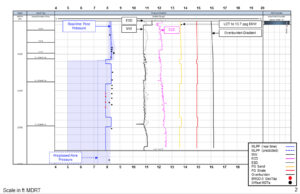

With this well, which had a measured depth (MD) of 12,642 ft and true vertical depth (TVD) of 3,925 ft, Hess aimed to prevent losses and maintain wellbore stability in the 8 ½-in. lateral section. Modeling showed the level of breakout at different mud weights ranging from 10.6 lb/gal to 11.2 lb/gal. Understanding limited level of breakouts need to be tolerated, Hess chose a 10.8-lb/gal mud weight for the section as a reconciliation between wellbore stability and lost circulation concerns.

Hydraulics modeling showed that ECD for the section would range between 12.3-12.9 lb/gal at the 10.8-lb/gal mud weight. However, even at that mud weight and ECD, the section could still see losses if the pore pressure fracture gradient was on the low side due to depletion. Hess formulated a “stress cage” to prevent losses in case of low pore pressure fracture gradient. A stress cage is a wellbore strengthening model of the mechanism that boosts up the fracture gradient to be above expected ECD through the addition of mud additives.

The 8 ½-in. section was drilled at an average ROP of 50 ft/hr, with a pump rate of 450 gal/min and a rotation of 140-150 rev/min. The ECD stayed primarily within the range indicated by hydraulics modeling (12.0-12.6 lb/gal). Stress cage was implemented prior to drilling into depleted reservoir as precaution.

Reservoir pressure was then measured by the Formation Pressure While Drilling (FPWD) tool once the sensor was in contact with permeable formation. Based on that, the fracture gradient was expected to be higher than the ECD. The stress cage materials were deemed unnecessary and then screened out. The well was subsequently drilled to total depth (TD).

Dr Yao noted the importance of collaboration between different stakeholders in drilling the well without any losses. “We put tremendous scrutiny into our plans for the wellbore strengthening material ahead of time, and during the operations we had a lot of eyes looking at screens while the drilling was happening to see how everything was performing. Communication and collaboration were key during the whole process.”

The well also provides a valuable blueprint for handling similar wells in the future, he added. DC