Native crude reduces formation damage in CT-drilled laterals

On-site program minimizes volatility of fluid for underbalanced coiled-tubing drilling program in Texas

By James Myatt, Stephen Lynn, Steven Craig, Stuart Murphy, Pedro Correa and Tomas Padron, Baker Hughes

Fluid selection is an integral part of every well drilling operation, as the choice of fluid can mean the difference between success and failure in delivering an economical and technically successful well. Increased drilling costs, coupled with a trend toward more complex reservoirs, are driving the search for high-performing fluids that heighten safety and lower environmental risks.

A fundamental consideration in fluid selection is the elimination of formation damage caused by incompatibility between the fluid and the reservoir. One method of avoiding potential incompatibility involves using a fluid native to the reservoir, also known as a native crude.

Formation damage risks are acute during drilling operations in the Buda formation in Texas, a naturally fractured lime bound by the Eagle Ford and Del Rio shales. Production success has depended on using horizontal wellbores to maximize fracture contact with the reservoir and minimize formation damage through proper selection of drilling fluid.

The technique of underbalanced coiled-tubing drilling (CTD) has proven successful in drilling laterals in the Buda formation. Using native crude as the drilling fluid may provide additional benefits, including the fact that volumes returned to the surface may be transported for sale or added back into the active fluid system. The native fluid would not adversely affect the relative permeability in the fracture throats should the pressure system inadvertently enter an overbalanced state.

Further, compared with a brine-based mud system, underbalanced conditions are more easily achieved in the low reservoir pressure environment encountered while drilling.

However, these benefits are balanced with operational risks. The Buda formation contains H2S at levels that could introduce an H2S content of 40,000 ppm (4%) or more into the native crude. Additionally, an untreated native crude is inherently volatile and raises explosion and fire risks. Recirculation of sour crude can also lead to double-sided exposure of the coiled tubing, which translates to short fatigue life or premature failure.

These challenges prompted Baker Hughes to develop an on-site fluid testing program, coupled with a defined mitigation plan using H2S scavengers and corrosion inhibitors, to ensure the fluid properties remain within a desired scope of volatility and H2S content and to reduce risks to acceptable levels.

Managing Volatility

The first part of the program focused on developing a protocol for lowering the volatility of the native crude. The primary indicators used for classifying the volatility of crude are flashpoint and Reid vapor pressure (RVP), a property that establishes the relationship between flammability and the lighter hydrocarbon molecular content of the native crude.

The RVP of a representative native Buda crude ranged between 7.1 and 8.0 psi, while its flash point was -35°F, making the crude significantly more volatile than other hydrocarbons commonly used as well service fluids. A No. 2 diesel, for example, has a RVP of 0.2 psi and a flash point of 165°F.

A peer review process and analysis by internal subject matter experts suggested that if the crude were weathered to a point where its RVP was less than 5 psi, then the overall fluid volatility would be reduced sufficiently to limit its flammability in the field.

Two common methods for weathering crude are the addition of an indirect heating source and agitation of the liquid to remove the light ends. A recirculation system utilizing ambient weather conditions with a long fluid retention time was sufficient to remove the light ends and lower the crude’s RVP prior to circulation downhole (Figure 1). Nitrogen was introduced to aid underbalanced conditions and to reduce the RVP by lowering the hydrocarbon partial pressure.

As an added level of assurance, Baker Hughes designed a sequenced response plan to make incremental adjustments in operations when RVP began trending above 4 psi. This plan called for increasing the residence time in the recirculation system, diluting the fluid with nonvolatile sweet crude, and decreasing the separator pressure while circulating fluid with the pump to create agitation. Two tanks of sweet crude were reserved and kept separate from the well operating volume. If RVP began trending too high, the reserve sweet crude could be fully brought online to give the weathering process more time to lower pressure or to enable to the team to continue limited drilling or pick up to a safe depth.

Crude samples were periodically taken from the recirculation system, and the RVP was measured per the method outlined in ASTM D323, with modifications to accommodate field conditions.

Case History

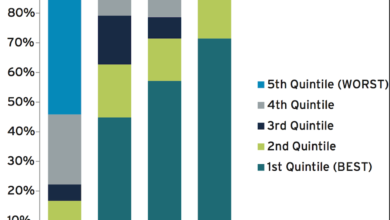

The in-field RVP circulation system was tested prior to live operation by using a pump to circulate the native crude in efforts to reduce fluid volatility. As shown in Figure 2, an initial RVP value of 5.4 psi was recorded before pumping began. Within 24 hrs, the RVP decreased below 3.5 psi as expected. The rate at which the crude light ends flashed off was high initially and became more asymptotic over time. Testing was ended after 4 psi was sustained.

An analysis of the RVP trends suggested that the circulation system’s weathering process was successful. While

introducing produced fluid into the active system, the RVP value was reduced or maintained throughout the four-well campaign. Figure 3 illustrates an example of the active system for one of the completed wells over a 14-day period. Sampling was increased during operations as lateral exposure increased and more production was observed.

In another well, RVP increases prompted the Baker Hughes team to initiate the sequence response plan. Fresh production was decreased, and the nonvolatile sweet crude was introduced into the system to maintain and reduce RVP levels.

The differently applied mitigations once these mitigations were combined, the efforts of natural heating, agitation and surface retention time yielded crude that was weathered to an acceptable level to satisfy project-specific safety standards.

Mitigating H2S Exposure

The potential for H2S contamination from the Buda formation is a significant safety concern to rig crews and surface equipment. The harsh environment created by recirculating the sour native crude also directly affects the coiled-tubing metallurgy. Left unmanaged, irreversible damage in the form of hydrogen embrittlement or hydrogen induced cracking (HIC) occurs, resulting in reduced operational life or even premature failure.

Inhibitors and H2S scavengers were utilized to mitigate the risk of HIC on the coiled tubing. An inhibitor injection point was planned at the oil leg of the separator, and an H2S scavenger injection point was placed at the suction tank.

Frequent on-site testing was conducted to ensure the applied mitigations were successful. Every two hours, fluid samples were pulled and placed in Dräger gas detection tubes; the concentration of H2S in the fluids was indicated by the intensity of the color change observed in the tube.

Two sweet crude tanks (900 bbl) were placed in-line to provide non-hazardous fluid on demand throughout operations. While drilling the second well, flowback personnel observed high volumes in the active system tanks and made an emergency decision to divert sour crude into the sweet crude tanks.

The first sample from the suction tank measured a concentration of 10,000 ppm H2S, indicating that the coiled tubing encountered double-sided exposure to H2S-saturated fluid. To counter these high H2S levels in the suction tank, scavenger injection was increased by maximizing the run rate of the chemical injection pump. Even after treating the active system with scavenger and venting to an atmospheric ammonia scrubber, H2S levels in the fluid remained high. Subsequent to this exposure, the safe working life of the string was reduced, enabling operations to continue with the use of H2S inhibitors.

CT Sample Testing

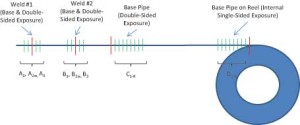

After completing the second well, 22 coil samples were cut from the string and tested to determine the extent of damage from the H2S-saturated crude. Fatigue testing showed that samples taken at section D on the reel end (Figure 4) experienced internal single-sided exposure. Samples taken at sections A–C had been in the wellbore and experienced double-sided exposure.

The fatigue testing conditions used a bending radius of 59 in. and an internal pressure of 2,000 psi to mimic field conditions. After testing, the sum of the measured laboratory and observed field fatigue was compared with the mean fatigue expected under sweet drilling conditions. The bias welds failed prematurely, indicating sour exposure had caused a fatigue reduction compared with the expected mean sweet fatigue. While the internal cracking historically observed with double-sided exposure was not present, the reduction in fatigue life could have been associated with “embrittlement” caused by the sour exposure (i.e., hydrogen diffusing within the bias welds).

Pipe body samples were collected at different points on the string to determine the effects of single- and double-sided exposure. The fatigue life (of both single- and double-sided exposures) was greater than historical single-sided H2S exposed pipe. The variance for the comparisons could be associated with an outgassing effect (i.e., hydrogen diffusing out) and with the use of the more benign native crude.

Double-sided exposure was confirmed due to the collected pipe body samples C and D having the same range of fatigue reduction, even though sample D was never exposed to the wellbore. The historical testing of double-sided exposure in an aqueous environment has historically shown large extreme reductions in fatigue life compared with sweet and single-sided exposure.

Lessons Learned

The process of recirculating volatile and sour native crude posed a challenge while drilling horizontal wells in the Buda formation. However, an in-field fluid characterization and processing system proved useful in addressing both volatility and H2S content. The RVP for the native crude was weathered over time by circulation, with initially high values quickly brought down to acceptable manageable ranges below 4 psi. The H2S mitigation was only partially successful in these first operations because the fluid retention time was less than desired, preventing the surface equipment from removing more H2S. While the operation resulted in the coiled tubing experiencing double-sided exposure, the resulting damage was still less severe than it would have been in an aqueous environment. According to design, the inhibitor prevented HIC from occurring, and the use of native crude helped reduce the severity of corrosive attack more efficiently than water-based fluids.

The service provider will use the lessons learned in this operation to develop improved circulation systems to increase fluid retention time and make native fluid circulation safer, more efficient and more effective in the Buda formation.