New liquid microsphere design simplifies HPL cementing, enhances density flexibility

By David Kulakofsky, Halliburton

As wells become increasingly complex, so do the cementing solutions required to support the casing strings and reliably isolate pay zones for long-term economics in these deeper, hotter, higher-pressure and even corrosive environments. A popular solution is a family of high-performance lightweight (HPL) cementing systems based on hollow-microsphere material supplied in a bulk additive form to be blended with the cement powder. These microspheres deliver the benefit of providing cementing solutions with normal density slurry properties at lightweight and even ultra-lightweight systems, allowing complete circulation in complex wells – even past the weakest zones.

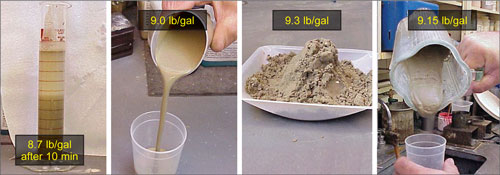

Figure 1: The LBA mixture allows microspheres

Figure 1: The LBA mixture allows microspheres

to be provided as a stable liquid additive

that maintains uniform distribution.

While there is growing popularity worldwide of HPL cementing solutions based on microspheres, achieving the prescribed slurry properties when bulk blending microspheres into the cement powder has proven particularly challenging. Microspheres can throw off conventional-quality assurance measures of the slurry properties (especially the necessary cement-to-water ratio). Thus, complex operational modifications and unique best practices are recommended for delivering a successful primary cement job.

Well-documented challenges from bulk-blend microsphere-based HPL cementing systems include:

- Complex blending procedures.

- Long blending times.

- Large bulk storage requirements.

- Special bulk transfer procedures.

- Unique mixing requirements.

- Requirements for modifications to the standard slurry mixing equipment to allow the correct cement-to-water ratio of the slurry.

- Slurry density inflexibility.

For instance, because the spheres are hollow, the bulk volumes required can double, triple or quadruple, which can lead to storage issues. Additionally, with the requirement to ship cement blends offshore days or weeks ahead of time, inability to adjust the density may lock the cementing engineer into the preplanned density even if well conditions change.

Halliburton offers an alternative that helps to eliminate these concerns, including enabling last-minute density flexibility.

It is important to note that rather than blending the microspheres with the cement powder, there are successful jobs where bulk microspheres were added directly to the mix fluid. However, in instances where the microspheres are just added to the slugging pit, there is nothing to assure that the delivery of the microspheres is uniform. Slugging pits and batch mixers typically have their suctions at the bottom and, because the microspheres tend to rise or float rather than sink, any floating of the microspheres can result in the early fluid near the suction having a reduced microsphere concentration.

This article introduces the use of microspheres in a liquid additive form and describes not only how it overcomes the blending, transport and storage challenges of bulk microspheres but also how it enhances evaluation of the cement slurry properties to achieve the engineered design for a successful primary cement job. In the subject liquid-bead additive (LBA) preparation, only enough fluid is used to liquefy the microspheres. Thus, if the liquid injection rate is accurately metered, the microsphere delivery should be uniform.

Figure 2: The density inflexibility of non-LBA HPL

cementing systems can pose challenges for offshore operations.

SOLUTION

Rather than a high-performance lightweight cement slurry based on bulk-blended microspheres, a less problematic approach to HPL involves a new concept of an LBA. LBA is a proprietary mix that allows microspheres to be provided as a stable liquid additive (Figure 1) that maintains a uniform distribution of the microspheres. Creating HPL cements utilizing LBA instead of the conventional method of bulk blending microspheres with the cement powder addresses all seven of the normal complications associated with these otherwise advantageous HPL systems as outlined in Table 1.

Since the microspheres are suspended in liquid, a common concern engineers might raise with solid particles suspended in a liquid additive is settling and the formation of a sludge at the bottom of the container (a potential problem with even the most stable of preparations).

However, with the LBA material – although very stable (Figure 3) – if settling was to occur, the material would float up, not down, thus allowing easy re-homogenization. As such, the most common problem with other liquid additives is avoided.

Figure 3: LBA mixture is stable, with the material

Figure 3: LBA mixture is stable, with the material

floating up, not down, to allow for re-homogenization.

The LBA system can be used in two ways. One approach is for the base slurry to be batch mixed. Once the slurry is up to weight, the LBA is added, creating the HPL system to complete the blend that is then pumped into the wellbore.

A second approach is to introduce the LBA mixture using standard liquid-additive-injection methodology. With this technique, the actual low-density slurry is mixed conventionally instead of with the special slurry mixing techniques or equipment that is required for standard HPL systems. As the density decreases, the specific gravity of the bulk material approaches that of the mix fluid, with conventional blended HPL systems. This prevents control of the cement-to-water ratio using the standard density-based mixing system.

With LBA technology, after the LBA is injected into the mix water feed-system, the mix water becomes lighter and the conventional blend specific gravity of +/- 2-2.5 provides the required difference to allow a conventional density-based mixing system to control the cement-to-water ratio.

STRESS-PROTECT YOUR HPL SOLUTION

With recent understanding of stress-related sheath failure and a new selection of elastomeric and fibrous additives, it is possible to design HPL slurries at low densities while also providing unprecedented levels of stress protection. In SPE 97168, the Minerals Management Service (MMS) described how the initially successful annular seal provided by the cement sheath can begin failing at an increasingly alarming rate as wells age.

Table 1

Future wellbore activities, such as pressure or well testing, production cycling, injection and stimulation treatments, among other events, cause stress levels to build in the cement sheath. As these stresses build up and are repeated, the cement sheath can form small radial cracks or micro-annuli. These sheath failures can lead to the sustained casing pressure documented and discussed in 97168.

To address this issue, the industry developed additive systems that could decrease brittleness and increase elasticity and resilience. When components that deliver resiliency are combined with LBA-generated HPL systems, operators have access to an easy-to-deliver lightweight system capable of providing a successful long-term annular seal.

The most recent advance in these life-of-the-well solutions includes a modification to the elastomers that allows the sheath to react and respond to flowing hydrocarbon in the annulus to swell and self-repair should the seal ever fail. Upon detecting flowing hydrocarbon, these react-and-respond cement sheaths can expand 1-2%, auto-sealing the crack or micro-annuli. With well-documented technology now available to help maximize production and minimize operating expenses, why use old technology across important production intervals?

SUMMARY

Cementing technology is staying ahead of the escalating complexity of downhole environments and wellbore architecture. Halliburton provides a way of simplifying complex HPL cementing jobs with a liquid-bead additive system that can overcome all of the challenges typically associated with HPL cement systems while still delivering the benefits of a lightweight or ultra-lightweight cementing solution.

Additionally, elastomeric and/or fibrous cement additives provide for a resilient cement sheath that can withstand the cumulative effects of stresses on the cement sheath due to changing downhole conditions to enhance the economic life of the well.

This article is based on a presentation at the IADC World Drilling 2009 Conference & Exhibition, 17-18 June 2009, Dublin, Ireland.