Odfjell Technology achieves significant time reduction in BOP cleaning trial

Odfjell Technology, an integrated supplier of offshore drilling, well and engineering services, has achieved 50% reduction in cleaning blowout preventers (BOPs) during a successful trial.

Over a test period of six months, Odfjell Technology revised the procedure for cleaning the BOP on the Johan Sverdrup platform in Norway by increasing the pump rate to allow more water flow into the BOP cavities to aid debris removal.

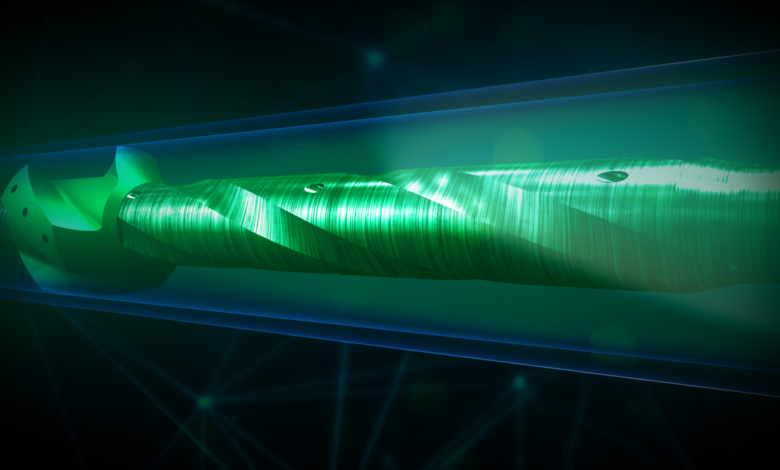

The annular and variable rams were flushed with two passes at the new recommended flow rates to remove debris, then the BOP stack was flushed at the same rate using Odfjell Technology’s RizeRdillo Advanced Jetting Tool. The flow rates went from 1500 liters/min to 5,500 liters/min while flushing the annular and from 3000 liters/min to 5500 liters/min while flushing the BOP.

Results from the successful test period proved that no damage occurred to the BOP and annular with the recommended pump rates, and between six and 12 hours of time could be saved using this new procedure.

“By focusing on delivering world class expertise and technology which enables more efficient operations without compromise on safety, Odfjell Technology proves it is the partner of choice for customers time and again,” said Ian Low, Global Product Line Manager, Well Intervention at Odfjell Technology. “Our ethos has been demonstrated by our expert teams achieving this impressive industry-first result for cleaning BOPs. BOPs are essential for safe and efficient well operations, and we are proud to deliver leading solutions to our customers to ensure BOPs are operating at optimal levels.”