Moonpool dance on the Pacific Santa Ana: Subsea MudLift Drilling system deployments pave path to deepwater DGD

Lessons gained, improvements made in GOM project as system moves toward commercial launch

By Frédéric Jacquemin, Pacific Drilling, and Dale Straub, Chevron

To paraphrase Van Morrison, it’s a marvelous night for a moonpool dance.

The Pacific Santa Ana is the world’s first purpose-built, dual-gradient drilling (DGD) rig. Delivered from the Samsung Heavy Industries shipyard in December 2011, it arrived in the Gulf of Mexico in May 2012 with a mission to deploy the first commercial DGD system using Subsea MudLift Drilling (SMD) technology. This article describes the SMD kit and its deployment in the US Gulf of Mexico, and outlines the ways in which the technology can be used to enable exploration of drilling frontiers.

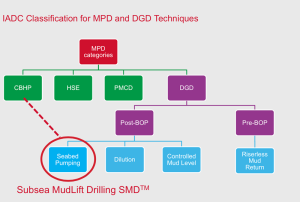

IADC classification

IADC defines managed pressure drilling (MPD) as “an adaptive drilling process used to precisely control the annular pressure profile throughout the wellbore. The objectives are to ascertain the downhole pressure environment limits and to manage the annular hydraulic pressure profile accordingly.” The industry recognizes four MPD methods: the most commonly used constant bottomhole pressure (CBHP); health safety and environment, or return flow control; pressurized mud cap drilling or alternative floating mud cap drilling; and DGD.

IADC defines DGD as “two or more pressure gradients within selected well sections to manage the well pressure profile.” Different ways to achieve a DGD system include a seabed pumping method, a dilution-based method (with solids, liquids or gases), a controlled mud level method, or simply a riserless mud return solution.

Value propositions

Operators select a particular MPD technique for various reasons. MPD allows for better detection of, reaction to and control of kicks, which also should be smaller in an MPD scenario. Other drivers for using the technology include the virtual elimination of lost circulation due to ballooning formations; typically more efficient cement jobs and fewer squeeze jobs; more predictable well duration outcomes; and a significant reduction in hidden downtime leading to improved reliability.

In deepwater, DGD brings additional value, such as the ability to restore a full riser margin; a reduction by design in the number of casing strings; reduced casing pressure loads; and new completion options since the well arrives in the reservoir with a bigger diameter.

SMD technology

The Chevron SMD technology is most commonly categorized as a seabed pumping method of DGD. It was developed with the objective to allow drilling a narrow-margin deepwater well with a full dual-gradient mud column, with seawater density above the mud line and heavy mud below the mud line. However, Chevron quickly realized this kit could also be used to maintain CBHP in either dual-gradient or single-gradient mode, and in a manner where annular friction pressure can be either trapped or pumped off.

The MudLift Pump (MLP) is the heart of the SMD system. It is located near the seabed, right above the BOP and lower marine riser package (LMRP) assembly. Made of six 80-gal chambers and powered by filtered seawater coming from the rig through a 6-in. ID riser auxiliary line, the MLP pumps mud back to the rig through another 6-in ID mud return line.

The solids processing unit (SPU) is another primary component and sits above the MLP. It sizes the well cuttings to no more than 1.5 in. before they enter the MLP. The subsea rotating device (SRD) provides isolation and pressure differential from below or above, depending on its configuration (single-gradient or dual-gradient mode).

More than one tool in the toolbox

The SMD kit can be used for several purposes, either in dual-gradient or single-gradient mode. In all three examples discussed below, the SMD kit is deployed in 4,000 ft of water and the bit is at 20,000 ft true vertical depth.

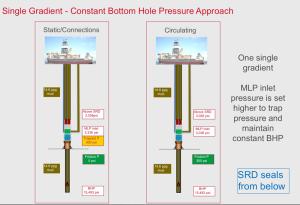

In the dual-gradient configuration (Figure 4), the riser is full with 8.6-ppg density riser fluid and a 16-ppg mud system below the mud line. This configuration reaches a bottomhole pressure (BHP) of 15,152 psi, which is equivalent at the bit to a single-gradient mud weight of approximately 14.6 ppg, while navigating much more easily through the drilling window. In this configuration, the MLP inlet pressure in static conditions is 1,840 psi. The MLP inlet can be set at 2,140 psi and trap 300 psi in static conditions, which can then be released progressively to maintain constant BHP while circulating.

In the single-gradient configuration (Figure 5), a static BHP of 15,183 psi is reached with a single 14.6-ppg mud column. The MLP inlet is set at 3,336 psi to trap 300 psi and maintain constant BHP while circulating.

This method is similar to conventional CBHP methods and useful to navigate through narrow pore pressure margins that can be reached with a single mud gradient.

In both approaches, a CBHP philosophy is used. Additionally, in both instances, the pressure below the SRD exceeds the pressure above the SRD, which therefore needs to be designed to seal from below.

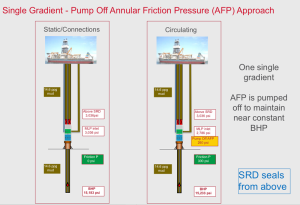

The third configuration (Figure 6) also uses a single mud gradient but uses the MLP to pump off annular friction pressure (AFP) while circulating. This configuration is ideal in pressure regression zones when trying to maintain a low, near-constant BHP while circulating. In this instance, Chevron designed the amount of AFP pumped off while circulating to ensure the well would never become underbalanced in the event of a pump failure. In this configuration, however, the pressure above the SRD exceeds the pressure below the SRD, which was therefore designed to seal from above.

The moonpool dance

Once fully assembled, the SMD kit cannot be run all in one operation with the LMRP and BOP. Instead, the lower BOP must be run first on drill pipe and then followed by the LMRP-MLP-SPU-SRD-riser running assembly. It is quite a dance; we call it the moonpool dance.

The MLP was loaded onboard the Pacific Santa Ana in June 2013, and the SMD kit has since been deployed four times.

The SMD system is not fully commercial yet and is in the final stage of obtaining regulatory and class approval, but each deployment leads to incremental lessons learned, further objectives demonstrated and experience accumulated. Chevron, Pacific Drilling, Enhanced Drilling and GE Oil & Gas crews jointly developed procedures to ensure smooth execution of the moonpool dance, with significant attention paid to planning and safety. Using the model of “Verify, Inform, Consult, Accountable, and Responsible,” matrices were developed to help identify roles and responsibilities.

The successes for the team to date are numerous. Through the deployments, the team has accomplished every major objective on the path from a prototype toward a fully operational system that may be used in a normal deepwater drilling environment. Nearly every component and sub-system has been deeply analyzed and frequently improved, and members of the team have grown significantly in their operational and diagnostic competence with the system. Equally important, the system is beginning to demonstrate unparalleled control of wellbore pressure and promises to address many of the pressure challenges typically seen in deepwater wells.

During the latest deepwater deployment, the SMD team worked through a comprehensive set of assurance tests drawn from requirements of the local regulatory agency, a third-party certified verification authority, and Chevron. The system worked well mechanically, and almost every test requirement was completed as planned. Most significantly, a well control test with a simulated kick demonstrated that the system is not only capable of supporting the detection of small influxes but these may be detected significantly sooner than in a conventional deepwater drilling operation.

However, there are a few remaining issues that must be fully resolved before Chevron can consider the system ready for open-hole operations. The system is operating on an extended deepwater soak test to further validate pressure integrity under extended subsea conditions.

In summary, there are multiple MPD and DGD techniques, each with different modus operandi and value propositions for a particular well challenge. Successfully deploying the world’s first SMD kit with the Pacific Santa Ana in the Gulf of Mexico was not the end of the journey but the beginning of a revolutionary tool. Finally, integrating new technology goes beyond proving new equipment; it is at least as much about writing and proving new processes and training the right people.

Can I just have one more moonpool dance with you, my love?

Subsea MudLift Drilling (SMD) is a trademark of Chevron.

This article is based on a presentation at the 2015 IADC/SPE Managed Pressure Drilling and Underbalanced Operations Conference, 13-14 April, Dubai.