IADC ART Committee moves closer to launching updated drill bit dull grading system

When completed, new system is expected to remove human subjectivity in grading process, support root cause analyses of bit damage

By Stephen Whitfield, Associate Editor

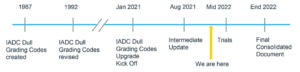

In 2021, the IADC Advanced Rig Technology (ART) Committee launched a project to upgrade IADC’s long-standing bit dull grading system. The objective was to develop a more modern system for understanding and grading bit wear that better supports workflows for root cause analysis and continuous improvement.

“The existing bit dull grading classification system needed to get a major upgrade,” said Robert van Kuilenburg, Mechanical Engineering Manager at Noble Corp and former ART Committee Chair. “It was heavily focused on the justification of pulling and not on the root causes. It relies too heavily on expertise, and there’s no framework for metadata inclusion and limited support for automated drilling systems. It just doesn’t cut it in today’s environment.”

The ART workgroup, led by Mr van Kuilenburg along with ExxonMobil’s Paul Pastusek, Shell’s Dustin Daechsel, and Data Gumbo’s Robin Macmillan, formed four smaller teams to examine different aspects of the upgrade process: drill bit code definitions; BHAs and motors code definitions; data management; and case studies. During a live Virtual Panel Discussion hosed by Drilling Contractor on 9 February, representatives from each team discussed the work they have done, their planned output, work items left to be resolved, and the estimated timeline to completing the system upgrade.

Drill Bit Code Definitions

This team set out on its task by recognizing that the current codes haven’t been updated since 1987. Not only do they not provide enough granularity on the types of damage experienced so that detailed root causes analyses could be conducted, but they also require human expertise and are subject to interpretation.

So the team set out to develop a qualitative classification scheme of PDC cutters, drill bits and tools with cutting elements, along with second priority on quantitative analysis. While the system will focus on PDC bits due to their market domination, the system will also be compatible with other bit types. Further, it recognizes different levels of dull grading.

“We’re looking to split the grade in terms of a rig grade, which is still similar to what we do today in terms of grading at the rig, and then we’re going to have the more accurate forensic shop grade,” said Tom Roberts, Vice President – PDC Strategy and Development, NOV. “The importance of the two is that the rig grade provides real-time decision making and is still extremely important, but both will come together in terms of advanced forensics.”

New damage categories, such as chamfer damage and axial break, were also added, along with a category of classes specifically designed to evaluate the wear on the substrates of PDC cutters. This was a critical addition because substrate damage can often indicate more substantial damage within the BHA, said Dustin Lyles, VP of Technology at Taurex Bits.

“When you look at, say, a corroded substrate and you see a lot of pitting, you know that’s a sign of either H2S or potentially caustic mud,” Mr Lyles said. “When that occurs on a drill bit, it’s obviously very critical for not just the drill bit providers but also the operators to know that there’s H2S present or that the mud is caustic. That lends itself into pushing that person or that organization into looking at other BHA components, because it’s likely that it’s not only the drill bit that’s experienced that type of corrosive damage.”

The group also oversaw an expansion of the bit zone categories, from just “inner” and “outer” to include the cone, the nose, the gauge and the shoulder.

“The historic ‘inner two-thirds to outer two-thirds’ system was very applicable to roller cones, but it was not very applicable to PDC bits,” Mr Lyles said. “We believe this type of improved granularity into the drill bit zones will give additional color and help drive the root cause forensic analysis.”

The next steps for the drill bits group are to finalize a training document with examples of the new wear categories. Later this year, the group also expects to conduct field trials, where companies will grade cutters and provide feedback on the effectiveness of the new categories. Further, this group will work with the data management team to develop a digital interface of the new categories for the IADC Daily Drilling Report.

BHA & Motors Code Definitions

This group is focused on the classification of the BHA, motors, RSS tools, stabilizers and other BHA elements and has been working to create a forensics evaluation workflow and best practices document for BHA coding.

“The bit dull grading system has served very well in creating a picture of the condition of the bit once it’s above rotary, and it has been a proven tool in improving performance. But there’s nothing that’s been done on the BHA side,” said Paul Neil, Senior Director of Drilling Solutions, Engineering and Reliability at NOV.

The BHA team is comprised of five targeted sub-groups, each tasked with developing a coding system specific to its area of focus: motors, rotary steerable, data acquisition, performance enhancement and iron (stabs, collars, subs).

The BHA coding is structured into three levels, where the first is a high-level examination of the BHA. At this level, users can quickly flag any issues with a part of the BHA that require review and investigation. This coding system lists six main codes indicating different types of damage or reasons for failure (no damage, back-off, washout, cracks, fracture) for different components within the BHA (bit, MWD, positive displacement motor, RSS, stabilizer, formation evaluation and perforation enhancement). Users can also note reasons for pulling the BHA.

Level 2 is designed to give users a detailed method for reporting issues with individual components within the BHA. In addition to the six main damage codes, it contains separate codes for the location of the damage, wear severity and field observations. Users can also note primary and secondary causes of damage or failure.

Level 3 will standardize classifications when performing root cause analysis and conducting post-run investigations of the BHA, although work on this section is not scheduled to begin until later this year.

This year, the BHA team expects to finalize the field coding system for each of its five sub-groups. So far, the BHA team has added 13 new categories to describe the reasons for pulling the BHA, and it established 46 new damage/failure codes. Mr Neil said the team will continue to update these codes once it conducts field testing later this year.

Case studies

This team focused on collecting case studies for the most common modes of dysfunctions encountered while highlighting their corresponding post-run forensic evidence. These case studies will be used for training, as well as to ensure that the codes developed by the other teams are adequate for forensics and continuous improvement investigations.

Willie Watson, Well Engineering Manager for Shell, described this team’s work as a means of synthesizing the work done by the other teams. It is linking the damage identified in the new codes from the drill bit and BHA teams with information gathered from its own investigations and polling of subject matter experts.

“As you start to investigate, you see what damage is caused by specific drilling dysfunctions,” Mr Watson said. “Our goal is to pull the information from our investigations together, combine the forensic evaluation with the actual conditions that drill bits and the BHAs have been exposed to, and use that to help us diagnose the failure.”

The team’s work to identify potential case studies focusing on common failures, which will be included in a best practice document, is still ongoing. A group of subject matter experts continue to review examples of failures and damage to see which ones are best suited for development as case studies and as best practices.

This group is also reviewing the codes proposed by the drill bit and BHA code definition teams to make sure they are necessary, unique and well understood, and that accurately describe the damage and current status of a given component. This work should be completed by the end of Q1 2022.

By Q2 this year, the team aims to define the standards for critical and the “nice to have” data required for each study and establish consensus among the teams on each standard. It will also gather and label a set of photo and digital data examples of various damage/failure codes for human and machine training.

By Q3 2022, when field trials of the updated bit dull grading system are complete, the team will document the frequency of occurrence of different degradation modes to use as a priority guide for human and machine training. After that, the team hopes to create a forensics evaluation workflow and continuous improvement best practices document for industrywide rollout.

Data management

The data management team focused on developing a guideline to store codes, digital images and other metadata about drill bits. This digital data exchange guideline will be usable for machine learning tools and real-time data exchange on the rig.

“More and more people are involved with the data collection process, data management process, exchanging data and essentially getting a hold of data so that it could help them make good decisions,” said David Shackleton, IDS Business Development Manager at Schlumberger.

To create the guideline, the team investigated best practices for bit, BHA and surrounding data formats, and for collecting and classifying digital visualizations such as photos, videos and 3D models. In one chapter of the document, the team looks at different ways of storing and accessing data, data model types, and current standards such as PPDM and WITSML. Another chapter covers good practices in data management, focusing on the proper ontology, validation and verification for data.

Collection and storage of example data was facilitated by cooperation among the workgroup’s various teams. Based on these examples, the data management team was tasked with creating a training data set of forensics photos with agreed upon codes.

Work is still ongoing for the design, construction and eventual launch of the training data set. However, the guideline offers some suggestions for the industry to consider. It outlines possible structures for a training data set, as well as the role-based permissions companies can use to establish who gets access to the data. DC