Human factors among key topics to be tackled at Drilling Systems Automation Workshop

Understanding of human factors is growing in importance as the drilling industry pushes forward on automation. Industry experts have recognized this, and the Drilling Systems Automation (DSA) Roadmap Cross Industry Initiative Committee has established human factors as one its eight core sub-groups. The committee is creating a roadmap for how the industry can get to autonomous drilling operations by 2025. “Interest in human factors implications is growing. There is more recognition that this is something the industry needs to pay attention to,” Amanda DiFiore, Human Factors Manager for QinetiQ NA, said.

The DSA committee, along with the IADC Advanced Rig Technology Committee, will jointly hold a workshop on 15 September in Galveston, Texas. Ms DiFiore, who is leading the human factors sub-group, will provide an update of her team’s progress at the event. “One of the things I’ll be talking about is adaptive automation,” she said, referring to systems that can sense when the human operator is under high load conditions and if the machine should take over certain functions. On the flip side, the system also must know when human engagement is low and actively increase that engagement to keep the human aware of what’s going on.

QinetiQ NA, a subsidiary of a British company that grew out of the Ministry of Defense, provides technologies and solutions to diverse industries, from military to transportation to railroad. Ms DiFiore manages an R&D group of human factors engineers that examine issues around the human operator. “There are a lot of lessons being learned in the US railroad industry in terms of how they’re trying to automate their operations,” she explained. “They’re running into human operator issues in terms of identifying what types of activities can be automated successfully and how that impacts the existing operators.”

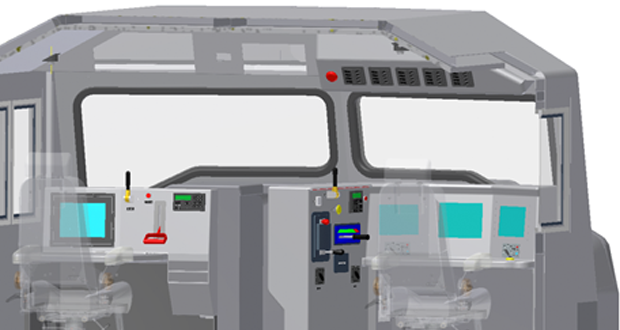

She explained that the US railroad and the oil/gas industries are in similar places along the path to automation. “Railroad is maybe one step ahead, so it’s easy to identify the pitfalls from that industry and directly apply that to oil and gas.” In particular, oil and gas has much to learn about how to design the human interface for drillers and other drilling personnel, she said.

“There are a lot of important lessons to be learned about the human in the loop and how automation affects awareness,” Ms DiFiore said. “When people don’t have high levels of work load to keep them engaged, their attention tends to wane, and their situation awareness tends to wander. If there is a system failure or emergency situation, it could be very hard for a human operator who’s monitoring the operation to re-engage. We have to be very careful about how we keep them engaged in the process, and that goes back to how we design the human-machine interface.”

In addition to human factors, the workshop also will feature presentations from other DSA sub-groups, including systems architecture; instrumentation, measurements & sensors; control systems; drilling machines and equipment; communications; and simulation systems and modeling. A keynote presentation by John Berra, Senior Advisor & Past Chairman of Emerson Process Management, will present lessons from the development of industrial automation and how to accelerate drilling systems automation.

To view the full program or to register for the workshop, please click here.

Automation is routinely used in the motor and airline industries – now is a great time to fully embrace automation in the Oil & Gas industry. Systems already exist in the Drilling domain to eliminate errors due to human factors and efficiently/consistently perform repetitive functions such as RIH, POOH, Friction Tests.