Virtual, augmented reality adoption on the horizon for drilling industry

VR technologies are already providing ROI in training applications, while AR applications face more limitations due to lack of explosion-proof hardware

By Jeff Sattler, Contributor

The technologies of virtual and augmented reality (VR and AR) are increasingly in the news. At the same time, many are wondering how much of this is marketing and whether projects using these cutting-edge formats are providing early adopters a return on their investments. This article will provide an overview on the current status of VR/AR as applicable to the drilling industry.

Definitions

VR is a computer technology that uses headsets to generate realistic images, sounds and other sensations that simulate a user’s physical presence in a virtual or imaginary environment. A person using VR equipment is able to “look around” the artificial world, move about in it and interact with virtual features or items. VR headsets are head-mounted goggles with a screen in front of the eyes. They isolate the wearer from their physical environment.

AR is a live direct or indirect view of a physical, real-world environment whose elements are augmented by computer-generated sensory input, such as sound, video, graphics or GPS data. AR enhances one’s current perception of reality. Well-known examples include the first down marker on televised football and the 2016 game blockbuster Pokémon Go. It is claimed that the term originated in 1990 with Boeing employee Tom Caudell.

Technology Application Forecast

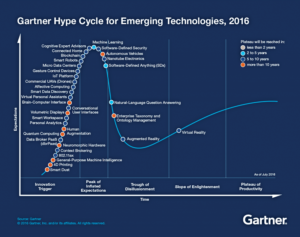

Information technology consultant Gartner has been producing forecasts of new technologies’ adoption with a tool it calls the hype cycle. The tool provides an outlook on “the promise of an emerging technology within the context of their industry and individual appetite for risk.” In Gartner’s 2016 hype cycle, it’s estimated that it will be an additional five to 10 years before VR and AR reach their plateau of productivity, or mainstream adoption, with VR reaching that stage before AR.

Another look at the current state of this technology is provided by Super Ventures, an early-stage fund and incubator that invests in startups utilizing VR and AR. In its consideration of the landscape, it showcases vendors who are developing AR applications, categorized into nine categories. Interestingly, none of these categories includes industrial projects.

Hardware

As all software must be built to run on given hardware, this may limit the application and functionality of VR and AR technologies in the drilling industry.

Hardware for VR is more mature than those for AR. Led by the videogaming industry, a growing number of VR-dedicated headsets are commercially available, with sales growing to 2.2 million in the first quarter of this year. The weak link in hardware for drilling applications is the user interface, particularly haptic, or interactions involving touch. While significant improvements have been recognized in the past year or so, applications today still require the use of controllers, which are different from natural interfaces in the field.

Particularly important is the progress being made in the area of utilizing the user’s hand movements to “execute” tasks. The physical feedback one experiences in reality, such as touch, heat, etc, are yet to be made available. On the other hand, the use of controllers, while sub-optimal, still makes for an acceptable training experience.

With AR, many other hardware limitations exist. The most significant is that there are no glasses available at this point that are certified as usable within Class I, Division 2 (or 1) electrical classification. Several manufacturers have announced their expectation to receive this certification in the near future, but there is no confirmation yet. Without this rating, use outside of unclassified workshops or warehouses is not feasible except for special circumstances. It should be noted that there are EX-rated cases that can allow smart phones and tablets to be used in these areas.

Another issue is battery life. Many consider 12 hours, one shift, to be the absolute minimum. Weight, processing power and heat generation are also usability issues of concern.

Case studies

VR – Helicopter landing officer training

Today, there are no industry standards for helicopter landing officer training. Standards are generally applied on an operator-by-operator basis. One major Gulf of Mexico (GOM) operator implements its standards by sending the trainer and trainee offshore for both initial and refresher training.

The VR project was justified based on a variety of economic and technical drivers. Financially, eliminating the need for offshore refresher training, now required every two years, provides ongoing savings for transportation to rigs and platforms. The operator chose to continue to conduct initial training offshore for now.

Regarding training effectiveness, the following factors are accretive in better overall results from VR training: ability to simulate scenarios that are not achievable in real-life training, e.g. helicopter crashes; and consistent training and results analysis, which leads to easier and error-free competence record keeping. Studies have shown experiential and immersive VR training exceeds other remote training methodologies, approaching that of “live” information transfer and retention rates.

AR

As best as can be determined, there are no applications of AR currently being used as part of industrial operations. However, there are many active pilot programs, the earliest starting from the early 1990s. It is reported that some projects are “a few months away” from production use.

Remote Expert

The great crew change, probably exacerbated by the precipitous drop in crude oil prices, has long been a concern in the industry. The low price environment also mandates aggressive yet prudent cost cutting. The remote expert application is soon to be field-tested by a major drilling equipment manufacturer’s field service unit. While this is a relatively simple application – the technician in the field enables experts at a remote location to see what he sees and makes available information to that technician – hardware, connectivity and enterprise security all remain difficulties to be ironed out.

Manufacturing and Maintenance

Once again, a number of major companies are working on pilot projects to assess technical viability for AR applications in manufacturing and maintenance. One study, conducted by Iowa State University for a Boeing wing assembly in 2015, reported a 90% increase in first-time quality, along with a 30% reduction in build time. Another pilot in the assembly of a Boeing wiring harness, published in 2016, reported a 25% decrease in manufacturing time and “significantly” reduced error rate. Similarly, many companies report pilots for maintenance tasks.

The annual Maintenance, Reliability and Operations aviation conference has been conducting maintenance contests where teams from technical schools and airlines’ working mechanics compete for recognition. In 2017, one of the 19 stations utilized a tablet-based guided work instruction to assist contestants with their required task. The sponsor of that station reported being impressed with both the time savings, as well as the accuracy of the completed task. An additional reported benefit was having documented the completion of and time to complete each step in the process. This information can be used to analyze procedures for further optimizing.

One future state

Although the following is certainly a plausible future, it is neither the only possibility nor an expected reality within a given time frame. What most assuredly will happen is portions of this technology will be implemented as technology and financial returns become available, building on processes and systems used today. With foresight, the process can be expedited if one develops solutions with an expansive view to an integrated and comprehensive solution.

Futuristic Operations and Maintenance

When the shift starts, the drilling staff dons their gear, which includes AR glasses. Upon signing in, they access key activities of the prior shift relative to their responsibilities. Hyperlinks provide access to supplementary data, like comparisons to the drilling plan, deviations therefrom, LWD/MWD data, maintenance issues, etc. It could also include reports from the beach, recorded audio or video, and safety briefings.

Next up would be expectations for work for their upcoming shift, with similar job-specific supplementary data and studies. Planned maintenance activities and operational responsibilities relative to those roles would also be displayed, as well as a timeline of required tasks generated by a critical path scheduling tool to optimize efficiency. This task list will coordinate and balance isolation and safe work permit obligations with the planned drilling activities and other maintenance activities.

Concurrently, maintenance staff will receive information pertinent to their jobs. With tasks assigned, tool and part requirements will be distributed to their respective warehouses, and procedures, drawings and historical information will be loaded for easy reference. As steps in each procedure are completed, data are recorded in the maintenance system. These include things such as date, time, technician, step verification, time to complete, photos of critical operations, serial numbers of the parts installed and removed, and quality of the replaced part. Many of these data, once recorded, are analyzed for improvements to procedures, training and replacement criteria.

The location of everyone on board will be known. This allows the real-time spatial display of hazards, both ordinary and transitory, to people as they move around the rig. For example, areas at risk from lifting operations can be displayed as yellow cylinders under the planned path, with the immediate risk area updated as a red column as the load is transported to its destination. This will simplify area isolation, as well as provide a definitive record to exposure to hazards for near-miss data. Additionally, as environments change, workers will receive real-time updates, minimizing reaction times to developing hazards.

Summary

Today, VR projects are providing ROI in applications where training requirements formerly required on-site remote attendance at specialized training facilities. The ability to immerse students in scenarios that are impractical to reproduce in real physical situations is a considerable benefit for training for unusual and infrequent situations. This has long been utilized in training aircraft pilots. These ROIs are particularly compelling when required training locations are offshore.

Hardware limitations make ROI-generating projects more difficult with AR technology today. On the other hand, maintenance applications in other industries without the explosion-proof hardware requirement are being piloted by numerous companies, so modifying these to work with new hardware will allow for rapid expansion into the drilling industry once the hardware allows. DC

This article is based on a presentation at the 2017 IADC Asset Integrity & Reliability Conference, 22-23 August, Houston.

Click here to view a video interview with Jeff Sattler on VR and AR technologies.

References:

https://en.wikipedia.org/wiki/Virtual_reality

https://en.wikipedia.org/wiki/Augmented_reality

http://www.gartner.com/technology/research/methodologies/hype-cycle.jsp