Technology will sustain energy renaissance despite lag in oil prices

Continental: Allowing crude oil exports is another step to push US energy independence to next level

By Joanne Liou, Associate Editor

Robert Kennedy is Corporate Engineering Manager for Continental Resources.

At the 2013 IADC Annual General Meeting, you talked about the energy renaissance driven by horizontal drilling. What challenges does this renaissance face as oil prices fall?

At the 2013 IADC Annual General Meeting, you talked about the energy renaissance driven by horizontal drilling. What challenges does this renaissance face as oil prices fall?

Horizontal drilling is now the norm in our industry, and every year the wells get deeper and the laterals get longer. This advancement in drilling has fostered the evolution in completion technology to where it is today. That has not changed in the face of falling oil prices. In the short term, oil prices are down, but global energy demand is still strong. As long as we continue to make technological advancements, we really don’t see an end for the energy renaissance.

How can operators address increasing costs?

I don’t foresee costs continuing to increase in this environment. We’ll probably see a 15% decrease in costs across the board over this coming year.

Consolidation is an opportunity for operators with a large presence in any given area. One of Continental’s strengths is that we’re the largest acreage owner and the largest operator in the Bakken and in the SCOOP (South Central Oklahoma Oil Province). We’ve spent a lot of energy consolidating into those two areas and partnering with efficient vendors that focus on the long-term value versus chasing short-term swings. Supply chain management plays a crucial role in maintaining a strong relationship between operations and the vendor community.

What challenges do you face as an independent oil and gas producer?

The development of horizontal drilling has allowed independent oil and gas producers to lead America’s energy renaissance. We have the opportunity to take energy independence to the next level if we can allow the free trade of crude oil as we do for other petroleum products. Major oil and gas companies already export approximately 4 million barrels per day of refined petroleum products, like gasoline and diesel. America’s outdated crude oil export restrictions must be changed to allow domestic oil exploration and production to achieve its full potential.

What challenges do you see on the technology side?

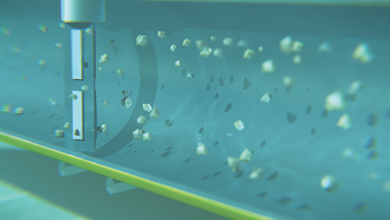

Drilling and completion technologies have dramatically advanced over the last decade. This rapid advancement has put a lot of pressure on production gathering and processing operations. We’re having to design horizontal wellbores in a way that we can use existing artificial lift technology that was designed for vertical wells.

The next phase is to design technology to make use of existing horizontal wellbores. We shouldn’t have to limit the curve to a certain dogleg severity or to require a tangent, and the lateral should not be required to be drilled up-dip. We shouldn’t change the wellbore design but should change the technology to fit the wellbore.

Further, artificial lift technology has to deal with a wide range of variable flow in shale production. It will have to handle gas and solids and function at ever-lengthening laterals.

This is the next logical phase in the energy renaissance. Drilling was the tip of the spear, followed closely by completion techniques. The next challenge is to improve artificial lift technology.

What improvements would you like to see in completion technologies?

Advances in stimulation have allowed us to produce oil and natural gas from formations that used to be uneconomic, but we still have a lot of opportunity to improve stimulation techniques. For example, in the Bakken, we have tried several combinations of gel, slickwater and hybrids. There’s room to optimize the amount of fluid, the type of fluid and the amount of sand or proppant. There is not one right answer. Optimization will require an understanding of each area in order to design the stimulation to maximize impact.

The Bakken’s cumulative oil production reached the 1 billion barrel mark in 2014. What is the significance of this milestone? What are the bottlenecks to increase production?

The tightest restriction we have is a result of the current regulatory environment and access for take-away processing capability in the localized markets. The 1 billion barrel milestone validates the immense potential in the Bakken. Truly, the development is just beginning. Two-thirds of the billion barrels were produced in just the last three years. This is something that Americans can celebrate as the oil and natural gas industry continues to create jobs, grow our economy and secure our energy future. The industry needs to better communicate the challenges that we have and let the average person understand the benefits that we’re bringing to America.

As the largest producer and leaseholder in the Bakken field, what lessons have you learned along the way that you might apply to your other fields?

The biggest lesson with unconventional plays is how large they are and the need to drill the first well with full development in mind. You have to really consider everything that needs to be done, including the infrastructure, community service, housing, etc, prior to actually moving into a new area. You really need to meet with the community to help them understand the positive impact, as well as some of the challenges.

As an operator, you need to understand what the play is going to look like in development mode and start preparing for it from day one.

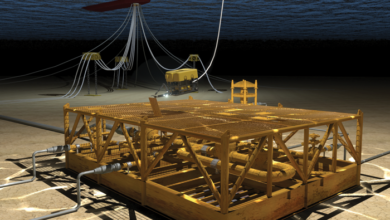

Continental Resources completed its first ECO-Pad project in 2010 in Dunn County, North Dakota. What is ECO-Pad, and how has it evolved since 2010?

ECO-Pad puts multiple wellbores into a smaller footprint. Over the past year, we’ve expanded it to include SIMOPS (simultaneous operations) so that we are drilling, completing and producing from the same pad at the same time. This has improved efficiency by bringing production forward, instead of waiting until all the wells are done before you can get production online. In turn, this allows for a more efficient and larger pad to be utilized with more wells, which further reduces surface impact.

Can ECO-Pad and SIMOPS be applied to your other fields?

Yes, we can apply the same science of understanding and operational efficiency to other areas of development. However, pads only go into high use in the development phase, which is when you really gain efficiencies. We have deployed ECO-Pads on development wells in the SCOOP. Right now, we’re focusing on operational fundamentals and continuing to improve the efficiency of the ECO-Pad and SIMOPS.

How can drilling contractors contribute to your efforts?

Drilling contractors can continue to work closely with operators to improve existing technology. The industry took a huge leap when it went from mechanical to SCR rigs and then to AC rigs. Wells continue to get deeper and laterals longer, and rigs and personnel in the oilfield have been challenged to the max. We need to keep evolving.

How would you like to see rig design evolve?

There are opportunities to automate more activities on the rig floor and the pits. We’d really like to allow rig personnel to focus the majority of their time on operational optimization. There’s a tremendous amount of efficiency to be gained by removing unskilled activities and allowing personnel to focus on the most impactful side of the business.

In your 2013 presentation at IADC’s Annual General Meeting, you stated that an estimated 55% of the workforce will become eligible for retirement by 2018, creating a gap of 100,000 workers. What more can the industry do to fill that gap?

Universities across the US are really putting their focus on energy-specific degree programs. In 2012, Continental Resources and our Chairman and CEO Harold Hamm each made separate donations of $5 million for a total of $10 million to create a school of geology and geological engineering at the University of North Dakota. Continental has also been helping to educate high school students about our industry. Our Funding the Future program, which provides grants for science, technology, engineering and math programs, helps to provide students with a foundation for succeeding in our industry.

At a field level, the energy renaissance has created a multitude of high-paying jobs. It’s uplifting to see the talent entering our industry.

How is Continental working to develop new talent once they join your company?

Continental is kicking off our Career Excellence Program to train and develop engineers across the company. Through this program, we’re working on identifying and evaluating the most impactful, meaningful and current classes for them to attend.

The strength of this program is that it targets both early career engineers and experienced engineers. It is a fluid program that allows you to take a look at any part of your career and continuously improve as an engineer. To sustain our workforce at Continental, we recognize that we must continually push people forward. This program is another way for us to reach out to the newer engineers and to capture experience from the more senior personnel.