Studies confirm performance of salt-free non-aqueous drilling fluid, bioremediation potential of cuttings

Multi-well study in Canada demonstrates NAF’s drilling performance while biodegradation study shows salt-free cuttings allow for plant growth

By Jonathan Walker, J.J. Miller and Kim Burrows, Halliburton; Timothy Mander and Jared Hovan, Formerly of Halliburton

Disposal of cuttings from nonaqueous drilling fluids (NAF) can be a significant expense and logistical issue for the operator of a drilling rig. NAFs typically contain high levels of salts, commonly calcium chloride or sodium chloride, in the internal phase of the emulsion. These salts are beneficial for wellbore stabilization but pose issues for cuttings disposal because the salts don’t biodegrade and can accumulate in high concentrations in soil.

A salt-free NAF has been developed and field-validated in the Western Canadian Sedimentary Basin in Alberta, Canada. The system uses a biodegradable organic to provide an internal phase with equivalent water activity to traditional salt-containing systems. This results in a fluid system with the performance and benefits of a conventional NAF while potentially allowing for greater cuttings disposal options. Depending on local regulations, the system has the potential to reduce environmental and long-term liability concerns by being able to land-farm drilled cuttings without hindering plant growth.

Three wells on a seven-well pad were drilled with the salt-free NAF, the other four with a conventional invert emulsion fluid (IEF). The salt-free fluid performed the same as or better than a conventional fluid while drilling. Observed improvements over conventional NAFs included less required fluid maintenance, greater inhibition of the formation and less fluid losses in part resulting from reduced oil on cuttings (OOC). A bioremediation study was conducted to analyze the cuttings for electrical conductivity and plant growth. Cuttings were sampled from each type of well and delivered to the lab for testing and analysis. Laboratory testing showed that, when mixed with top soil, the salt-free cuttings allowed viable plant growth. In comparison, the conventional cuttings did not allow plant growth.

The salt-free system showed equivalent and, in some respects, better performance to conventional NAFs used on other wells on the same pad. Additionally, cuttings from the salt-free system showed superior plant growth compared with conventional, salt-containing systems.

Background

IEFs are predominantly used instead of water-based systems because of their increased rate of penetration (ROP) and shale inhibition. When drilling with an IEF, salinity plays a crucial role in both fluid and shale stability. Salinity is usually referred to as water phase salinity (WPS). Brine, generally made up of calcium chloride and water, is added to the fluid formulation at certain concentrations of salt and water. However, chlorides within the fluid tend to adhere to the cuttings, causing cuttings disposal problems and environmental compliance issues. In environmentally sensitive areas, cuttings may need to be transported to onshore facilities. This can lead to high disposal costs and potential environmental hazards if treatment isn’t sufficient.

Because salt is a primary reason the cuttings cannot be disposed of without treatment, a salt-free system was developed to remedy this. The salt-free system discussed in this article uses a nonsalt internal phase. By implementing a biodegradable organic into the water phase, the desired shale stability can still be achieved by mimicking the WPS. Thus, the water is bound to the biodegradable organic and not allowed to hydrate the shale while drilling. Because there is no salt, a correlation between WPS and water activity was determined. This correlation allowed for the direct comparison of WPS with calcium chloride versus a WPS of the salt-free internal phase.

In a field trial in Canada, the salt-free system was used to drill three of seven wells on a single pad while the other four were drilled with the traditional IEF fluid common to the area. A 12 lbm/gal fluid was designed and tested in the lab before an identical formulation was mixed and used for the drilling operation. Samples of the fluid were taken through the job and analyzed for typical IEF specifications. Cuttings were also sampled and shipped to a third party for analysis. The remainders were sent to be treated through a thermomechanical cuttings cleaner and disposed of.

Without the salt interphase in the drilling fluid, the cuttings won’t be contaminated with chlorides and, thus, have the potential to be disposed of in a more cost-effective and environmentally friendly manner. The lack of chlorides may allow for plant growth if the cuttings were to be land-farmed, a cheaper alternative to other disposal methods. A biodegradation study performed by Sublette Consulting and the University of Tulsa is discussed in this article, with an emphasis on soil blending analysis and plant growth.

Laboratory Experimentation

Materials and Design of Experimentation

The new salt-free, non-aqueous fluid uses a proprietary biodegradable organic that replaces brine as the internal phase. The internal phase was premixed prior to its addition to the fluid, much like a traditional NAF formulation. All other additives were added to the fluid as received. A typical NAF formulation and comparative salt-free NAF formulation is shown in Table 1.

The equivalent WPS is measured using a water activity meter and a calibration curve. Through water activity, one can directly compare the aqueous organic value to that of a water activity value for any saturation level of calcium chloride brine. The curve was created through comparative dilutions of CaCl2 versus the biodegradable organic. Through the calibration curve, the equivalent WPS of the aqueous mixture was determined and could be correlated back to the active percent of the biodegradable organic.

Laboratory Testing

A formulation for the salt-free NAF was developed in the laboratory. Two major components of the fluid are the biodegradable organic as the internal phase and a proprietary oil-based mud stabilizer. The stabilizer provides suspension and filtration control in the fluid and is necessary at higher temperatures (300°F) to prevent sagging. These products are the backbone of the salt-free NAF and provide performance on par with a traditional IEF.

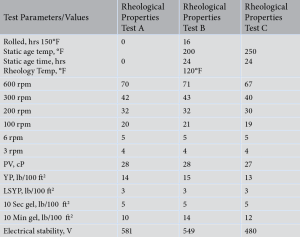

A 12 lbm/gal, 70/30 oil-water ratio (OWR) fluid formulation provided optimal laboratory results and was chosen with field trial applications in mind. The fluid was prepared using the biodegradable organic stabilizer and tested at various conditions. There was little difference in the fluid properties when static aged at different temperatures. Laboratory results can be seen in Table 2.

Field Trial

A field trial was conducted in Harmattan East, Alberta, Canada. Three wells on a seven-well pad were drilled with the salt-free system, while the other four were drilled with a traditional oil-based system. Comparisons of performance and fluid maintenance were made between the two systems, with emphasis on the ROP, OOC and fluid maintenance.

The salt-free system was implemented by a major operator. Drilling began without any issues, and the salt-free fluid behaved like a traditional oil-based mud. The desired properties of the mud were reached rapidly with no treatment of the fluid. The fluid was continually checked for fluid loss, water activity and chlorides content. The water activity was checked every hour since it is a critical attribute of the salt-free system and necessary for shale inhibition. Cuttings checks showed no hydration of the cuttings throughout the entire drilling process.

Advantages

The salt-free system outperformed the traditional system typically used in this region. The salt-free fluid saw an increase in ROP and a major decrease in OOC. There was very little treatment to the fluid while drilling, saving on fluid maintenance costs and NPT.

The drilling engineer on site noted the ROP for the salt-free system surpassed other fluid systems run in this region previously. The increased ROP led to faster completion of the well. In addition, the fluid required less dilution to maintain critical fluid properties. The rheology and fluid loss improved as drilling continued. Thus, the need to retreat the fluid was unnecessary. Also, the OOC was much lower than cuttings of a typical drilling fluid. The cuttings from the salt-free system measured at 12.4% OOC, compared with 23% for traditional fluid. It should be noted that the salt-free fluid system had a 70/30 OWR while the traditional fluid had an 80/20 OWR. This means the traditional fluid had an increased amount of oil from the beginning. Although this can contribute to some decrease in OOC, it is doubtful the value was halved by the difference in OWR. There were no signs of hydration of the cuttings, so the stability of the shale was not compromised.

Bioremediation Study

Samples of the cuttings were collected and shipped to the University of Tulsa for further analysis. A bioremediation study was conducted to determine the effects of the cuttings on plant growth. Because of the lack of salt, it was believed that plant growth would not be inhibited. This could lead to waste treatment opportunities, such as soil farming. Soil farming offers a more cost-effective method of treatment for cuttings disposal and is considered an environmentally safe technique. The study’s objectives were to understand any toxicity effects on seed germination and plant growth, including an analysis of electrical conductivity in the cuttings/soil mixtures.

Procedure and Analysis

Samples of salt-free and traditional IEF cuttings were sent to the University of Tulsa for side-by-side analysis. The cuttings were first separated into two bins and then mixed with locally sourced top soil at a 3:2 ratio and homogenized. After drying overnight, a small amount of fertilizer was blended with the cuttings/top soil mixture and moistened. Every day, the bins were moistened and mixed by hand with a new addition of fertilizer every few days. The goal of the mixing and retreatment with fertilizer was to decrease the overall total petroleum hydrocarbons on the cuttings that could inhibit plant growth and to study the electrical conductivity of the blended mixture that has been shown to be a direct factor of plant growth.

Results

The seed germination and plant growth study was performed upon completion of the bioremediation. The cuttings/soil mixtures were further mixed with varying concentrations of top soil and placed in pots. Fertilizer and water were added to each pot and stored at room temperature to facilitate an optimal environment for plant growth. In roughly 15 days, the plants that had grown were removed from the pots for root and nutrient analysis. Typically, soybeans show significant decreases in growth in soils with electrical conductivity levels >10 milli-Siemen per cm (mS/cm) and are even somewhat limited in levels as low as 2 to 4 mS/cm. Despite having low chloride content on the cuttings (approximately 26 ppm), the electrical conductivity levels were still higher than expected for the salt-free cuttings blends. While these blends recorded an electrical conductivity level of 10.7 mS/cm, this didn’t inhibit plant growth.

The plants were analyzed for root length, root mass, stalk length and stalk mass. While the 100% top soil plant showed the most profound plant growth, there was very little difference in root growth and root mass compared with the plants with increased cuttings material. There was a decrease in stalk length and mass. These appear to be the most affected by electrical conductivity levels. It should be noted that the traditional cuttings blend had an electrical conductivity reading of approximately 65 mS/cm and showed no plant growth during the 15-day period. This further proves that the salt is an inhibitor to seed germination and plant growth.

Conclusions

A salt-free drilling fluid for onshore drilling operations was developed in the lab and validated in the field through a trial in Alberta, Canada. The salt-free system proved to be effective during the field trial, showing higher performance in ROP, less fluid maintenance required and an overall decrease in OOC, all of which are attributes that could lead to decreased costs when drilling a well. The plant growth study was considered a success because of the amount of growth observed in the root length, root mass, stalk length and stalk mass. The salt-free cuttings were able to be mixed with typical potting soil and fertilizer to produce new plants while the traditional cuttings could not. DC

This article is based on IADC/SPE 178804, “Nonaqueous, Salt-Free Drilling Fluid Delivers Excellent Drilling Performance with a Smaller Environmental Footprint,” presented at the IADC/SPE Drilling Conference and Exhibition, Fort Worth, Texas, 1–3 March 2016.