Semisubmersibles vs jackups on Norwegian Continental Shelf: comparing the pros and cons

Noble undertakes review based on factors like NPT, waiting on weather, emissions and applicability of new drilling technologies

By Konstantin Puskarskij, Helge Talleraas, Bjarne Bertelsen, Ben Pomford, Michael Olsen, Kristian Engelbrecht Hansen, Per Frederiksen, Ida Maria Welhaven Winther, Adebowale Solarin and Robert Van Kuilenburg, Noble Corp

Approximately 30 of 73 offshore fields on the Norwegian Continental Shelf are located at a water depth between 100 and 150 m. Historically, two types of mobile offshore drilling units (MODUs) have been utilized to drill these prospects: column-stabilized MODUs (semisubmersibles) and self-elevated MODUs (jackups) of GustoMSC/NOV CJ70 design, which can operate at a water depth of up to 150 m.

Over the years, most of the advantages and disadvantages associated with using these types of MODUs have been identified. However, a periodic review of well-established conclusions can help operators to determine if adjustments are needed to reflect changing external factors. Noble Corp recently completed a comprehensive review comparing both MODU types based on nonproductive time, waiting on the weather (WoW), emissions footprint, drilling schedule predictability, drilling efficiency, the applicability of new drilling techniques and technologies such as managed pressure drilling (MPD) and riserless drilling, offshore logistics, and other essential criteria.

The review didn’t identify a clear “winner,” as both MODU types have strengths and weaknesses depending on the requirements applied; however, the assessment highlights some points that could be used for campaign-specific evaluations where a wider gap can be observed between both MODUs types on a case-by-case basis. This article presents selected points from the assessment.

Specific site assessment (SSA)

Seabed soil condition information is required to complete an SSA for jackups, and the timeline depends on the availability and accuracy of soil data. On some occasions, the SSA may require geotechnical and seabed surveys, including performing a cone penetration test or drilling a borehole under each future spud to position center. The SSA defines preloading conditions for the jackup arriving at the location, as well as limitations to the rig variable deck load (VDL) for various weather scenarios.

Mooring analysis

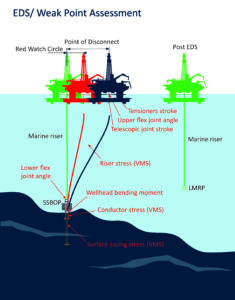

The mooring analysis for a semisubmersible depends on the soil condition, mooring spread design, inventory availability, decision on potential dynamic positioning (DP) assistance, subsea infrastructure at the location, and rig mooring capabilities. For shallow waters, the mooring (along with the riser) analysis significantly impacts the rig’s operability window. The rig offset, triggered by the environmental loads, may exceed the capacity of one or more weak points determined as a part of the weak point analysis. This could lead to a situation where the MODU may need to be disconnected from the well. The most common mitigation is utilizing DP assistance under certain adverse weather conditions in a disconnected drilling mode, which allows for handling higher environmental loads.

Wellhead analysis

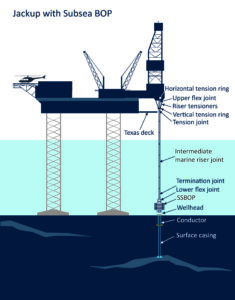

The upper well components and soil supporting the wellhead are exposed to external loads. Those loads are transmitted to the wellhead by the riser system, either by a marine riser for a semisubmersible operation or typically by a high-pressure (HP) or low-pressure (LP) riser system for a jackup operation.

The semisubmersible wave response, as well as VIV load effects on any type of riser from vortex shedding, is capable of inducing significant dynamic loads onto the wellhead and potentially reducing the fatigue life of critical components to a level that is below acceptable. Conditions are further exacerbated in shallow water due to the short riser length. Adverse metocean conditions at the location may aggravate the situation even further.

Mooring a semisubmersible on a shallow location (and using DP assistance when required) may mitigate the situation, to some extent, by dampening vessel motions. However, in some cases, more barriers could be required, such as a subsea BOP tethering system, wellhead and riser-mounted sensors for monitoring of motions and stress, a mooring system with a quick disconnect function, and, ultimately, planned emergency disconnect (EDS) from the well.

Marine riser analysis

for semisubmersibles

Marine riser analysis includes a set of assessments that highlight limitations to be considered during subsea BOP and riser deployment while staying connected on the well, when conducting drilling operations and also for control of emergency disconnect events, as well as hard/soft hang-off during wells hopping or storms.

For shallow-water prospects, the weak point analysis is the most crucial component of the riser analysis. It sets requirements for the mooring spread (and DP assistance where relevant) to secure the rig within the structural boundaries, where none of the weak point limits will be exceeded considering capacity criteria and methodologies for verification of extreme loads as outlined in API, ISO and DNV standards. For shallow-water drilling, the weak points usually are also associated with the upper part of the well and wellhead.

Riser analysis for jackups

HP or LP riser analysis for jackups with surface or subsea BOP is performed to verify that maximum loads for operating and survival conditions stay within predefined criteria. Fatigue loads need to be assessed as well, considering both the drilling riser stack-up and riser interfaces. For a number of load cases, it should be verified that the allowable component utilization will not be exceeded for the connected condition, which could potentially drive a decision to either suspend drilling and WoW or for a planned disconnect in case of extreme weather. Other verifications look at maximum loads on the horizontal guiding system top-side, loads on the diverter and overshot, and VIV adverse effects for the areas where a strong current is present or the riser is exposed to wind.

Transit, rig positioning and preloading

Jackups have a narrower weather window when they can be towed to the drilling site/stand-off location. Unfavorable weather may lead to extended WoW periods moving to or off the location.

A jackup’s positioning against subsea infrastructure or topside is a part of the SSA. Jackups of GustoMSC/NOV CJ70 design have a large cantilever envelope due to the X-Y skidding system design and cantilever size. These rigs can usually cover any subsea template or topside slots. On rare occasions where the jackup cantilever cannot reach all the slots from one location, the rig may need to be relocated.

Preloading activities are relevant for jackups where the preloading to the survival conditions of the rig simulates the loads on the soil that might be experienced in a 100-year weather event. Preloading activity has an in-built safety risk of punch-through, where the spudcan may penetrate the soil beyond what is expected, as well as WoW risks. The risk of a severe punch-through scenario has to be mitigated by the SSA and preloading procedures, while the exposure to potential WoW remains.

Variable deck load (VDL) and deck management

Due to the nature of their design, semisubmersibles are much more sensitive to the deck load, and their VDL is, in general, substantially lower compared with jackups of the CJ70 design. However, moving a CJ70 jackup closer to the 150-m water depth boundary may also negatively affect the rig’s VDL in some adverse weather conditions.

The CJ70 jackups have a significantly larger main deck space compared with semisubmersibles. The triangular shape of the jackup hull with an extended cantilever is optimized for deck management activities, where most areas can be reached by two or even three deck cranes. On the other hand, the logistics of semisubmersibles are restricted by the central arrangement of the derrick and drill floor.

Furthermore, deck cranes on a semisubmersible are also sensitive to wave-induced motions and can be unavailable for longer durations compared with the cranes on a jackup. Crane operations on jackups are only limited during periods when the wind exceeds a certain speed.

Shallow gas hazard risk reduction

Shallow gas is usually categorized as a gas accumulation that conventional techniques cannot control, either because the surface casing is not yet in place (BOP is not yet installed) or the well cannot be shut in due to low fracture pressures below the surface casing.

For semisubmersibles, the ability to move off location provides a significant risk reduction measure that is not available to jackups. This means preparations and requirements are generally stricter for jackups, including:

A seismic shallow hazard survey shall be conducted for exploration wells in areas with little to no offset data.

A shallow gas pilot hole shall be drilled if the above survey detects anything above a “low” risk of shallow gas. This hole shall be drilled to afford the possibility to divert any gas.

For legacy mature fields with existing producing or shut-in wells with charged annuli, the need to perform a resurvey shall be evaluated.

All wellbores shall be drilled a minimum of 100 m offset from the nearest shallow anomaly detected via the shallow hazard survey.

Top-hole drilling

Drilling top holes, running conductors and cementing can all be planned as a batch sequence for the subsea template. A semisubmersible can potentially drill top holes more efficiently if dual-activity operations are enabled. The conductor can be assembled in the auxiliary hole while the well is drilled via the main well center, or the conductor can be cemented as a parallel activity to another top-hole drilling.

Stationkeeping and WoW

Semisubmersibles, in certain weather, need to suspend drilling activities and secure the well. Sometimes, a semisubmersible must disconnect from the well and mooring spread, arrange hard/soft hang-off, or pull the subsea BOP to the deck.

Furthermore, if DP assistance mode is enabled for a moored semisubmersible, this significantly increases the emissions profile of the rig and drives well cost through increased fuel charges.

A semisubmersible, especially when operating in shallow waters, is more prone to WoW during drilling operations since the wave-loading drives increased rig motions, and rig accelerations may push drilling equipment, deck cranes and other machinery outside their operating windows. In some cases, the rig may also need to disconnect from the well to ensure that the marine riser, wellhead and upper well weak points remain intact.

Use of MPD

A semisubmersible operating in a harsh environment has proven to not be able to use surface backpressure (SBP) MPD techniques due to vessel response introducing a piston effect downhole. There are a few potential candidates for solutions, but they have not been tested and still are very much concepts.

Nevertheless, semisubmersibles can be retrofitted with a control mud level (CML) MPD system that is not as sensitive to vessel motion. Several CML campaigns have been successfully performed offshore Norway using systems installed on harsh-environment semisubmersibles. However, the usual sweet spot for a CML subsea pump installation is between 300 and 600 m of water depth; hence, the benefits of using the CML in shallow waters are to be confirmed due to the limited height of the empty column in the riser.

Passive heave compensation

Semisubmersibles have crown-mounted compensators (CMC). However, an extra barrier often has to be introduced to account for CMC malfunction or failure during locked-to-bottom operations (LTB). This may include safety bails, smaller compensated coiled-tubing lift frames, or similar.

Jackups do not require passive heave compensation during LTB operations since the rig is always static.

Simultaneous operations (SIMOPS)

SIMOPS, outside of the dual-activities domain, can be narrowed down to the Christmas tree (XT) landing while drilling another well. Theoretically, the semisubmersible can run the XT on the drill pipe via the auxiliary well center while still being connected to the marine risers in the main well center and performing drilling operations.

However, even in a benign environment, such SIMOPS activities are usually avoided due to too many risks to the subsea BOP, the marine riser and the subsea infrastructure. Hence, the preference often shifts to running the XT using a heave-compensated crane, by an anchor-handling tug vessel, or after retrieving the subsea BOP to deck.

Well hopping

Both MODU types can perform well hopping. A semisubmersible can do so-called kedging for a distance of up to 100-150 m in all directions. In contrast, a jackup is restricted by the cantilever reach envelope unless the rig can be moved.

In case a semisubmersible is not disconnected from the mooring spread, preparations for hopping operations may include collapsing the telescopic joint (TJ) and using a soft hang-off method on the marine riser tensioners for suspending the riser stack; however, this method usually doesn’t allow for sufficient clearance above the subsea infrastructure.

Another method is to collapse the TJ, pull one or more marine riser joints, and use a hang-off joint to split the weight between the spider and the top drive. The hard hang-off method may also use marine riser tensioners as a secondary retention if the load split between spider and top drive is not qualified for full redundancy.

A jackup with HP or LP marine riser and subsea BOP can pull one or more marine riser joints and split the load between the top drive and the spider while skidding the cantilever to the next well. In case access to the well is required, the HP or LP riser can be disconnected and placed in the hang-off frame installed at the jackup transom, then skid the cantilever to the next well and reconnect the riser.

Emissions on the well

By design, semisubmersibles uses more fuel and generate more emissions compared with jackups. The difference predominantly comes from thruster usage and the auxiliary systems serving the thrusters. Hence, if DP assistance is considered during adverse weather, a significantly higher fuel consumption and emissions profile can be expected from a semisubmersible. The larger hull volumes of semisubmersibles, including columns and pontoons, require significantly more powerful and energy-consuming ventilation systems than jackups.

In addition, mooring spread pre-lay and recovery activities require anchor-handling tug vessels, which have higher fuel consumption compared with conventional tugs used to move jackups to/off the location. Pre-laying and recovery are also more time consuming than towing activities.

If the MODU, either jackup or semisubmersible, has peak shaving technologies implemented, this can facilitate fuel consumption and emissions reduction efforts. In this scenario and measured in absolute numbers, a jackup’s fuel reduction is expected to be more significant than a semisubmersible’s since the DP capabilities are typically not covered by the batteries installed as part of the rig hybrid upgrade, and, as mentioned above, they are significant power consumers.

Furthermore, it is possible to feed the jackup by shore power from the fixed offshore platform where the rig is operating. In turn, the platform is hooked up to the grid. In theory, it is also possible to feed a semisubmersible with power generated by floating wind turbines or to establish a connection to the grid; however, this has not been tested in the field. DC

Click here access the Digital Reader for an extended version of Noble’s assessment.