Pressures amp up as rig counts keep falling

Amid low prices and a vast oil oversupply, drilling industry may need to look to strategic partnerships and diversification for survival

By Stephen Whitfield, Associate Editor

As the economic impacts of the COVID-19 pandemic drag on and the reality of a much-lower-for-longer environment really sets in, oilfield companies are recognizing that finding a path to survival has become more critical than ever.

The WTI price has shown some slight improvement since its crash in late April, reaching $40.73 on 22 June. While this price still reflects a 36% drop from the 2020 high – $63.05 on 3 January – it is much closer to the mid-$40s, where the WTI averaged in the first week of March. That was just before the World Health Organization declared COVID-19 a global pandemic.

- At the start of July, the Baker Hughes rig count was at its lowest figure since the service began in 1940. US rig count has declined for 17 consecutive weeks from 13 March to 2 July.

- Traditional cost-cutting measures, like warm-stacking rigs and reducing staff, may be inadequate for drilling contractors in handling the current oil price downturn.

- The trend of contract cancellations and suspensions that began at the onset of the COVID-19 pandemic is expected to continue through the end of the year.

With that said, the WTI would likely need to rise above $50/bbl before operators begin investing in new projects at a high enough level for drillers to see any increase in their cash flow, according to Jim Wicklund, Managing Director of the Energy Group at Stephens, an independent financial services firm. And while he believes WTI could potentially reach $50 in 2021, he also pointed out that NYMEX WTI Crude Oil futures indicate WTI will not reach that level until July 2028. This will likely make banks hesitant to back significant investment in new oil and gas projects.

“If an oil company says oil’s going to get back to $50 next year, the bank might say, that’s great, but the futures strip doesn’t get us back there until 2028. My response would be that I think it’s wrong, but do we want to make an investment decision based on my gut instinct that the futures strip is wrong? That’s the problem,” Mr Wicklund said. “Banks look at the futures strip to judge oil company reserves. This is why you’re seeing banks cutting their lending.”

In addition to futures pricing, other hurdles remain. Despite vast production cuts from OPEC+, world supply has far exceeded demand over the past few months, creating a surplus of around 1 billion barrels of oil and oil products in storage around the world. Burning off that excess will take time.

“We have to work through that simultaneously with demand recovery and bringing storage back to normal levels. We have to work through all of that before price starts to recover to the point where we really see new FIDs coming up,” said Harish Hemmige, Managing Director and Partner at the Boston Consulting Group (BCG).

Without financial backing, opportunities for drilling contractors to gain solid footing will diminish. Such an environment may not be favorable to the industry as a whole, but it could reward companies willing to think outside the box and embrace new ways of working.

Rig count and dayrates

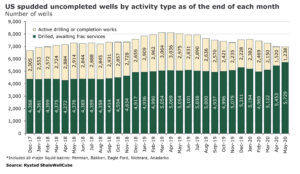

Prior to the COVID-19 pandemic, the US shale industry, in aggregate, was losing money. Now, faced with a new normal of lower oil prices, reduced demand, capital constraints, heavy debt loads and COVID-led economic uncertainty, the industry is entering a period of “great compression,” according to a study from Deloitte released in late June.

According to the study (“The Great Compression: Implications of COVID-19 for the US Shale Industry”), challenging oil market and economic conditions could prompt the shale industry to impair or write down the value of their assets by as much as $300 billion. As a result, the leverage ratio of the industry could increase from 40% to 54%, setting off a chain reaction of insolvencies and restructuring.

Deloitte reported that 30% of shale operators are technically insolvent at a WTI price of $35/bbl (as of 30 June, the WTI was at $39.30). As asset impairments and write-downs increase debt ratios, an even greater number of companies could become at risk for bankruptcy.

New telecommuting norms, regionalized trade and supply chains, and the stable business profile of new energies have fast-forwarded the specter of peak demand to the present. While a combination of global production cuts, the easing of lockdowns worldwide, CAPEX reductions and accelerated field decline rates have helped WTI recover from its crash, Deloitte said it remains to be seen if prices will return to $50 or $60 this year.

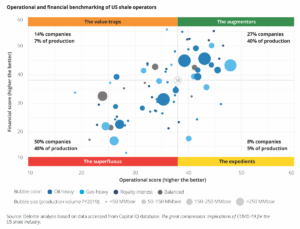

The study analyzed the operational and financial health of US shale operators, finding that only 27% were “augmentors,” or companies that could become likely takeover or merger targets for companies with healthier balance sheets that are looking to acquire new assets.

Conversely, approximately 50% of major E&Ps were identified as “superfluous,” or risky bets for potential buyers.

Deloitte said the double impact of COVID-19 and global oil oversupply have led investors to shun shale stocks, reversing the optimism the market felt about shale following the 2015-2016 downturn.

Deloitte said the grim financial reality could trigger deep consolidation in US shale. The report recommended that

E&Ps move quickly to save capital and reduce costs. In the long term, survival may require the evaluation of their entire business models.

“The short-term outlook for US shale is undeniably challenging, but E&Ps should regard the great compression as a unique opportunity for reinvention,” said Scott Sanderson, Principal, Oil and Gas Strategy and Operations at Deloitte.

“Selective consideration among producers in the short term can help revitalize the industry and better position it for the future. Investment in big data, advanced digitalization and sustainability measures can be of paramount importance to long-term survival and success.”

While 2020 figures to be a difficult year as oil demand is not expected to return to pre-pandemic levels anytime soon, Deloitte said the big unknowns in projecting beyond this year are the post-COVID environment and the role that OPEC will play in balancing oil supply. DC

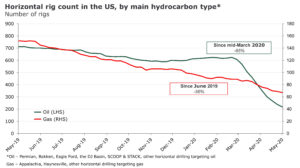

COVID-19’s impact on US oilfield services has been steep. The Baker Hughes rig count for 2 July saw total US rigs drop to 263, the lowest figure since the service began in 1940. That week marked the 17th consecutive decline in rig count and the ninth consecutive record low.

As of 2 July, only three major basins have 20 or more active rigs: the Marcellus Shale (28 rigs), the Haynesville Shale (33 rigs) and the Permian Basin (126 rigs, a record low). At the same point last year, nine basins had 20 or more rigs, including 439 in the Permian.

Mr Wicklund said that he expects the US land rig count to flatten out starting in July, then see a slight recovery by the end of the year as larger operators who had slashed activity bring some of their rigs back online. However, a recovery to pre-COVID levels is unlikely any time in the near future, especially as banks and private equity focus on funding companies that generate positive returns on investment capital (ROIC).

According to Mr Wicklund’s research, the 21 US land-focused E&P companies that have gone public in the past 10 years have generated a loss of $96 billion in market cap. With potential lenders emphasizing positive ROIC, they will likely not fund as many oil and gas projects as they did pre-COVID. This, Mr Wicklund said, will affect rig counts for a long time.

“A large part of our production increase over the past few years was non-economic, but we had a lot of investors willing to throw money at us in the form of equity and debt. But now, banks are cutting back on what they’re lending E&P companies, the public debt markets are effectively shut for energy, and no one’s been able to monetize an E&P company because the equity markets are shut,” Mr Wicklund explained. “If the capital goes to the companies that generate a positive return on capital investment, then I’m not sure that the US onshore rig count for oil will ever get back to where it was a year ago.”

Offshore, the picture is not rosy either. The count for active offshore rigs in the US has dropped by more than 50% from June 2019 to June 2020, according to Baker Hughes. At the beginning of the year, Rystad Energy had expected to see an increase in offshore floater demand in 2020, driven by higher activity in exploration and development drilling. However, based on the current backlog for floaters, the market is already down 13% from 2019 levels.

Further, the trend of contract cancellations and suspensions that began at the onset of the COVID-19 pandemic is expected to continue through this year, according to Liz Tysall, Senior Offshore Rig Analyst at Rystad. A large number of development projects have been moved into 2021, and exploration drilling this year is all but canceled. This could lead to a year-on-year drop of 18% demand for floaters from 2019.

Ms Tysall pointed to rates in the jackup market as another point of concern. At the beginning of the year, Rystad was seeing strong demand in key jackup markets – the number of contracted rigs had gone up by 8% from 2018 to 2019, amid ambitious investment outlooks from national oil companies (NOCs). This had led the firm to anticipate an estimated 6% increase in jackup demand for 2020. Now, that outlook has been flipped on its head, with the firm expecting a 6% decline in demand from 2019 levels.

Recovery of jackup dayrates had been going fairly well pre-COVID, with several regions – the Middle East, Southeast Asia and West Africa – reporting rates above $100,000/day. Now, rates are tumbling back down as operators request rate concessions, some reportedly as much as 30%.

Ms Tysall also said dayrates for ultra-deepwater rigs were worth noting. Because these rates had never fully recovered from the previous downturn, any further drops will put dayrates that much closer to an offshore driller’s operating expenditures. “At the beginning of the year, we were just beginning to see benign ultra-deepwater rates move toward the mid-$250,000 to $260,000 range for spot work. We were expecting rates to cross the $300,000 threshold for work with longer lead times. But now, drillers are turning their focus to just keeping their rigs contracted.”

Coupled with a weak backlog and the fact that many drilling contractors have interest payments and note payments coming due over the next 12 to 18 months, offshore drilling contractors will likely face a far more difficult time trying to survive this current downturn than they did the previous one.

New ways of thinking

As the industry adjusts to a new economic reality, the pressure to cut costs is perhaps greater than ever. BCG has seen an average 22% reduction in capital so far this year, compared with December 2019 projections, and expects that reduction to jump to 25% by year-end. In fact, 2021 could see additional reductions in the range of 25% to 30%, Mr Hemmige said, noting that operators need to reduce their unit costs by 20% to 50% to break even.

Rystad is estimating a 25% decline in global demand for oilfield services, though it said drilling contractors could see a gradual recovery in demand for their rigs over the next three years, following a $16 billion drop from 2019 to 2020. E&P spending should move up slightly from $46 billion in 2020 to $47 billion in 2021, then to $54 billion in 2022 and $57 billion in 2023, according to Rystad.

While demand for rigs may pick up in the longer term, Paul Goydan, North American Energy Practice Lead at BCG, said that in the short term, traditional cost-cutting measures like warm-stacking rigs and reducing staff will be inadequate for drilling contractors in handling the current downturn, primarily because they hadn’t yet bounced back from the last one.

“The drilling contractors haven’t had time to put any fat back on. They’re already going into this downturn lean,” Mr Goydan said. “What are your traditional cost-cutting avenues? The first thing you do is defer maintenance. Then you’re going to lay down crews. After that, there’s not much left in your company where you can manage costs, and your costs are almost proportional to your revenue. So you’re going to skip warm-stacking and go straight to cold-stacking. You’ll take the hit on capital equipment degradation in the downturn.”

In a recent report, “A New Reality for Oilfield Procurement and Supply Chains,” BCG described the importance for operators and drillers to build strategic partnerships with each other to drive out mutual costs.

Mr Goydan cited a 2018 BCG benchmark study that showed a direct relationship between drilling performance and dayrates among the 10 largest operators in the Permian; the companies that paid more for their rigs saw lower costs per foot for their wells.

- As of 2 July, only 3 major US basins have 20 or more active land rigs: the Marcellus Shale with 28 rigs, the Haynesville Shale with 33 rigs and the Permian with 126 rigs, a record low total. The count for active land rigs has dropped by more than 50% from June 2019 to June 2020.

- Despite an estimated 25% drop in global demand for oilfield services this year, drilling contractors could see a gradual recovery in demand for their rigs in the next two years, following a $16 billion decline from 2019 to 2020. Rystad Energy anticipates E&P spend to increase from $46 billion in 2020 to $47 billion in 2021, then to $54 billion in 2022.

- With 2020 exploration activity down to almost nothing and a large number of offshore development projects being postponed to 2021 or later, year-on-year floater demand could fall by 18% this year.

- WTI may need to rise above $50/bbl before operators will invest in new projects at a level high enough for drilling contractors to see noticeable increases in their cash flow.

“If you’re a drilling contractor and you have an edge – say, you have good equipment or you have good workers – there may be a way to come through this downturn with the right partnership,” he continued. “You need to work collaboratively in a way that shares the pain with your customers and allows everyone to survive. The operators don’t benefit if you lay off your people and cold-stack your rigs. If you can find a way to partner with your customers to save the core of the business, there may be a ray of hope to not have to go through a restructuring process.”

Mr Wicklund cautioned that the largest contractors are better positioned to capitalize on strategic partnerships and possibly some mutual consolidations, but that the near-term future will see more smaller contractors declaring bankruptcy, with balance sheets that impede consolidation.

However, he does believe that diversification can help contractors to survive. This means having additional services to offer operators.

“Instead of just offering a rig, some companies are offering directional drilling services, they’re offering wireline, they’re offering a range of associated services,” he said. “Companies like Patterson-UTI and Nabors have made acquisitions in the last three years outside of just buying rigs. They’ve made investments in ancillary businesses that take place while a rig is onsite, so they’re synergistic from that perspective. That will help them to transform their businesses and better weather something like this.”

Mr Wicklund also believes the downturn will accelerate the adoption of automation and digitalization technologies and systems – both on rigs and in offices – that could drive further efficiencies.

“People think about the technology on the rig, but the technology of running a company can have just as much of an impact here,” Mr Wicklund said. “What happens if I bring in a better, more efficient enterprise resource planning system, and I can do with 10 people what I used to do with 20? Over the last couple of years, drillers have embraced automation and more modern business practices. They have become nimbler and more effective in cutting overall costs this cycle because they have to think of new ways to reduce their variable costs. The old way to do it was to stack rigs and lay people off. Now, they need to do it with technology.” DC