Petrobras finds success in using adapted MPD techniques for deepwater completions operations

Prevention of hydrocarbon and fluid migration, limitations of intelligent well completions among key considerations in the Brazilian pre-salt

By Eduardo Schnitzler, André Alonso Fernandes, Carolina Bertholdo da Cunha, Fernando Salatiel de Oliveira, Guilherme Siqueira Vanni, Ricardo Freire Grandi, Roger Savoldi Roman and Rafael Almeida de Jesus, Petrobras

Brazilian oil and gas production has progressively migrated to offshore areas during the past decades, with the most prolific plays being found in the Campos Basin deepwater blocks. This scenario has led to significant technology development and application, turning Petrobras into one of the most experienced deepwater operators.

In the past 12 years, new discoveries have been made not only in the Campos and Espírito Santos basins but also in the Santos basin, a new frontier in Brazilian deepwater. While sandstone reservoirs had been the standard, limestones reservoirs, like the ones found in pre-salt plays, started to play a big role in production development.

One of the main concerns with well construction in this new scenario was the risk of severe fluid losses and wellbore stability during the drilling and completion phases. In some wells, overbalanced drilling and conventional loss control materials (LCM) have not been capable of coping with losses. In some cases, it was not possible to reach all goals in a safe and cost-effective manner. Therefore, unconventional drilling techniques like managed pressure drilling (MPD) have been applied, both for drilling and completions.

Background

The Lula field is located in the pre-salt cluster in the Santos basin, and is located in ultra-deepwater, between 2,000 and 2,200 m. The Jabuti reservoir, a post-salt carbonate located in the ring fence of Marlim Leste in Campos basin, was discovered in 2005 and is located in water depths between 1,200 m and 1,500 m. Similar accumulations – Jurará and Muçuã – were discovered in 2007 in Marlim Sul ring fence.

While well construction in both scenarios had been feasible with conventional techniques in most of the initial wells, in a few of them, there were significant issues related to total fluid losses and wellbore stability. In Campos basin post-salt limestones, these problems have been exacerbated by the depletion caused by production in other wells. In the Santos basin pre-salt natural fractures, vugs and karsts are frequently found in the reservoir.

Drilling activities in the Jabuti reservoir were temporarily interrupted due to the depletion causing severe losses, stuck pipe and the inability to reach final depths on the wells. The well construction team was challenged to develop a solution for building the remaining wells in a safe and efficient way.

Also in pre-salt plays, a few wells could not be safely and efficiently drilled to final depth. In some wells, all the available LCM technologies were applied, with no success on stopping the losses. In one of them, 10 cement plugs adding up to almost 4,000 bbl of slurry, were displaced into the loss zones. Even so, only a short advance on drilling depth was achieved. Eventually drilling into that problematic zone was halted due to safety and economic constraints.

Within the alternatives considered, MPD with dynamically positioned rigs was seen as the most appropriate solution. The completion team was also involved to develop the completion solutions to be used, as the reservoir would still be exposed while running the completion.

Since 1998, Petrobras has been conceiving, developing, testing, field-proving and commercially applying MPD technologies. It has selected three techniques – surface backpressure (SBP), pressurized mud cap drilling (PMCD) and floating mud cap drilling (FMCD) – depending on well requirements and conditions. MPD systems for SBP and P/FMCD operations involve installing and using specific surface and subsurface equipment on the rig selected for the job.

Completion Design and Installation Procedures

The SBP and PMCD techniques essentially require the use of a rotating control device (RCD) on top of the drilling riser to contain pressure below the rotary table. In these MPD variations, statically underbalanced fluid is used, and surface pressure must be applied to avoid influx of formation fluids to the surface. Even in the FMCD technique, in which the fluid level is below the rotary table, the RCD is used to deal with any undesired gas that might come into the drilling riser due to hydrocarbons migration.

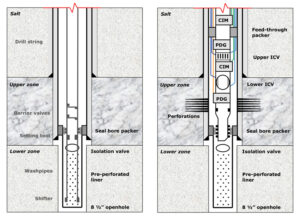

The RCD is responsible for sealing the annulus between the inside of the drilling riser and the drill string when tripping, making connections, rotating and drilling. However, the completion systems used in offshore wells usually contain accessories like control lines, clamps, mandrels, valves, packers and a tubing hanger – items that prevent the RCD from sealing against the production tubing. Therefore, a separated lower completion assembly capable of temporarily isolating the reservoir must be installed before running the upper completion. This assembly must be shorter than the distance between subsea BOP and the RCD so that it can be assembled while one of the BOP shear rams is kept closed. Later on, this assembly will be run in hole with drill pipes in front of the RCD, like a regular trip during the drilling phase.

Common single-zone completions used in Petrobras already comprise a separate lower completion, so no major changes on the equipment is required. However, different procedures are required for running this assembly. The drill string has internal barrier valves (e.g. non-return valves) to provide the required safety barriers while running in hole. These barrier valves must be compatible with the operations to be done for completion deployment, like packer setting and testing, releasing the running tool, acid job and fluid displacement, as well as with contingency operations.

Another important feature is the ability to keep fluid injection through the annulus while tripping in hole, in order to prevent the migration of hydrocarbons while in PMCD or FMCD modes. The fluid strategy is also a key point for MPD operations in completion, as it defines the pressures on the bottomhole, along the whole well and on surface. Fluid must also be compatible with the equipment to be installed and with the stimulation operations. The most common strategy in MPD completions has been the use of water-based mud or treated seawater.

Multiple-zone completions for carbonate reservoirs, like intelligent wells completions (IWC) used in pre-salt areas, usually do not have a separate lower completion that isolates the formation during the whole upper completion deployment. It is usually run in a single trip after perforating the production casing to access the desired reservoirs.

To overcome this limitation, new designs for IWC were put in place (Figure 1). In this case, a separate lower completion is installed to temporarily isolate the loss zone, while the upper completion is installed on a second run. The MPD multizone completion solution used in the field up to now can only cope with severe losses in the lower zone. However, a different approach has been developed to deal with losses in other zones.

Regardless of the changes made on the completion designs, other changes are required on the overall completion projects. For example, non-essential trips have been avoided. When possible, the casing conditioning has been done with the drilling BHA, eliminating a dedicated cleanup run before deploying the pre-perforated liner. Final fluid displacement is normally performed after lower completion installation, except if the well is put in an overbalanced situation for wireline logging after drilling.

In cases where an upper zone must be perforated, that is performed either before drilling the MPD phase or after isolating the lower zone. Full attention must be taken with pressure differentials during lower completion installation, especially if the FMCD technique is applied, in which case a significant height on the annulus might be empty.

As a general rule, completion applications using the PMCD technique have considered the use of treated seawater or brine as light annulus mud (LAM) that is continuously injected to overcome fluid migration. Injection flow rate is based on the results of hydraulic simulations and considers a proper safety factor for each situation. In exceptional cases, synthetic-based mud (SBM) might be used as LAM, eliminating the need for continuous injection, as hydrocarbons migration is significantly slower in this fluid. However, this strategy has disadvantages in terms of completion equipment and acid stimulation.

Completions operations in FMCD always consider the use of treated seawater and continuous injection. If pore pressure is significantly lower than normal pore pressure gradient, the fluid level might be below the BOP, even in deepwater wells, causing a negative pressure on submarine equipment. A complete analysis on equipment resistance to negative pressure and its consequence must be done prior do the application.

Finally, if the completion is installed in SBP mode, continuous circulation through a drilling riser line and MPD automated chokes will be used to control downhole pressure and keep the well dynamically in overbalance. Usually a fixed SBP is applied, but the hydraulic model adjusted with pressure while drilling (PWD) data could be used as a downhole anchor point. Either WBM, SBM or treated seawater is used with SBP mode. This technique may get into PMCD if losses increase during installation.

Results Summary

Almost 10 deepwater wells have been completed by Petrobras with MPD. Results reveal increased efficiency compared with conventional techniques for wells facing severe fluid losses, drilled in high depletion reservoirs with wellbore stability issues.

Figure 2 shows a comparison between wells completed with conventional techniques in pre-salt fields, both with an IWC configuration and a single-zone design. This data, together with the results of wells completed in the Campos basin, show that MPD techniques in this scenario deliver wells with less deviation, on schedule and within cost. Well D is an IWC where major losses occurred after perforating the production casing, leading to a significant delay in the completion schedule (over 100% above average time).

Despite relying more on equipment performance and workforce training, MPD applications in completions have so far met the required safety standards. As a general guideline, completion with MPD techniques is performed only when these techniques are required during the drilling phase. Otherwise, conventional techniques are considered. In other words, it is a fit-for-purpose solution.

Regardless of all the challenges set up by a new technology, MPD has given access to oil reserves that would not be feasible with conventional drilling and completion. It has proven to be a safe and cost-effective solution for specific scenarios.

Future Challenges

The use of adapted MPD techniques for completion operations has been a reality in Brazilian offshore activities during the last few years. Nevertheless, the standardization of requirements, practices and procedures must be continuously assessed.

The use of a higher pressure for MPD subsurface equipment could benefit completion applications, as it would allow the use of treated seawater as LAM for a wider range of pore pressure scenarios. The development of improved and more flexible barrier valves for the drill string is important for completion and workover applications. Some of the next challenges in Petrobras will be the use of multiple-zone IWC solutions fully compatible with MPD techniques and the use of MPD for heavy workover operations. DC

This article is based on a presentation at the 2017 IADC/SPE Managed Pressure Drilling and Underbalanced Operations Conference, 28-29 March, Rio de Janeiro, Brazil.