2017 OTC Spotlight on New Technology Awards highlights 17 innovations

OTC has announced the 17 winning technologies that are receiving the 2017 Spotlight on New Technology Awards, recognizing innovative technologies significantly impacting offshore exploration and production.

Bigbore-IIE wellhead system, Dril-Quip

BigBore-IIe is a fully qualified wellhead system consisting of a DXe connection profile, integral high-capacity hanger lock-down, superior system fatigue and high-capacity running tools. It reduces the number of trips into the well, eliminates drilling/production lock-down equipment and allows for reduction of casing strings.

BigBore-IIe is a fully qualified wellhead system consisting of a DXe connection profile, integral high-capacity hanger lock-down, superior system fatigue and high-capacity running tools. It reduces the number of trips into the well, eliminates drilling/production lock-down equipment and allows for reduction of casing strings.

DXE wellhead connector, DRIL-QUIP

The DXe wellhead connector, suitable for HPHT and severe cyclic load environments, has a highly engineered locking profile and gasket design providing high structural capacity and high fatigue resistance. The technology of this critical connection is validated beyond API-16A-PR2/API-TR7 requirements with both structural and fatigue physical testing.

The DXe wellhead connector, suitable for HPHT and severe cyclic load environments, has a highly engineered locking profile and gasket design providing high structural capacity and high fatigue resistance. The technology of this critical connection is validated beyond API-16A-PR2/API-TR7 requirements with both structural and fatigue physical testing.

Omnirise minibooster, Fuglesangs Subsea

The Omnirise miniBooster is the world’s first barrier fluid-less and seal-less pump intended for permanent subsea applications down to 3,000 m. The system includes a unique subsea electric variable speed drive and was qualified as part of National Oilwell Varco’s Active Subsea Cooler system in partnership with Statoil, Shell, Chevron, Total and GE.

The Omnirise miniBooster is the world’s first barrier fluid-less and seal-less pump intended for permanent subsea applications down to 3,000 m. The system includes a unique subsea electric variable speed drive and was qualified as part of National Oilwell Varco’s Active Subsea Cooler system in partnership with Statoil, Shell, Chevron, Total and GE.

Ecostar electric tubing-retrievable safety valve, Halliburton

The EcoStar valve is the world’s first electric downhole safety valve. It eliminates hydraulic fluid to enable a fully electric completion system with no risk of exposing electronics to produced wellbore fluids while retaining the same failsafe mechanism as today’s conventional safety valves.

The EcoStar valve is the world’s first electric downhole safety valve. It eliminates hydraulic fluid to enable a fully electric completion system with no risk of exposing electronics to produced wellbore fluids while retaining the same failsafe mechanism as today’s conventional safety valves.

HCS Advantageone offshore cementing system, Halliburton

The HCS AdvantageOne offshore cementing system enables remote operations, has an integrated liquid additive system for precise slurry blending, and predictive maintenance capabilities with shore-based monitoring to help preempt equipment-related nonproductive time.

The HCS AdvantageOne offshore cementing system enables remote operations, has an integrated liquid additive system for precise slurry blending, and predictive maintenance capabilities with shore-based monitoring to help preempt equipment-related nonproductive time.

One-triP universal BOP testing tool, Samoco Oil Tools

The OneTrip BOP testing tool, developed in collaboration with Shell Offshore Engineering, can conduct BOP tests in one trip, eliminating the need for multiple trips along the stack and reducing a rig’s idle time by at least 50%.

The OneTrip BOP testing tool, developed in collaboration with Shell Offshore Engineering, can conduct BOP tests in one trip, eliminating the need for multiple trips along the stack and reducing a rig’s idle time by at least 50%.

Stones FPSO turret mooring system, SBM offshore

Stones FPSO’s innovative turret mooring system (TMS) incorporates a series of enabling technologies to become the deepest mooring system of any floating production unit and the first disconnectable TMS to support steel risers. These new technologies will facilitate future developments in ultra-deepwater and of high-pressure, high-temperature reservoirs.

Stones FPSO’s innovative turret mooring system (TMS) incorporates a series of enabling technologies to become the deepest mooring system of any floating production unit and the first disconnectable TMS to support steel risers. These new technologies will facilitate future developments in ultra-deepwater and of high-pressure, high-temperature reservoirs.

MPD integrated solution, Schlumberger

![]() The managed pressure drilling (MPD) integrated solution is the industry’s first complete, all-OEM, reservoir-to-flare-stack deepwater MPD system. When MPD design, engineering, manufacturing, system integration, well engineering and onsite well delivery services are delivered from one platform and from a single supplier, operators minimize rig footprint while maximizing drilling efficiency and versatility.

The managed pressure drilling (MPD) integrated solution is the industry’s first complete, all-OEM, reservoir-to-flare-stack deepwater MPD system. When MPD design, engineering, manufacturing, system integration, well engineering and onsite well delivery services are delivered from one platform and from a single supplier, operators minimize rig footprint while maximizing drilling efficiency and versatility.

Optidrill real-time drilling intelligence service, Schlumberger

The OptiDrill Real-Time Drilling Intelligence Service enables continuous real-time condition monitoring by integrating a comprehensive set of drilling dynamics and mechanical information. The service mitigates drilling risk and improves performance by providing actionable information to continuously identify hazardous drilling dynamics events and trends and recommending safe operating parameters.

The OptiDrill Real-Time Drilling Intelligence Service enables continuous real-time condition monitoring by integrating a comprehensive set of drilling dynamics and mechanical information. The service mitigates drilling risk and improves performance by providing actionable information to continuously identify hazardous drilling dynamics events and trends and recommending safe operating parameters.

Real-time fatigue monitoring system, Stress Engineering Services

The Real-Time Fatigue Monitoring System (RFMS) has been developed to provide fatigue damage of drilling riser and wellhead systems. The wellhead is the last pressure-containing barrier between the well and environment. Managing the loads ensures that system integrity is not compromised and the environment is protected from hydrocarbon discharge.

The Real-Time Fatigue Monitoring System (RFMS) has been developed to provide fatigue damage of drilling riser and wellhead systems. The wellhead is the last pressure-containing barrier between the well and environment. Managing the loads ensures that system integrity is not compromised and the environment is protected from hydrocarbon discharge.

Compact mass transfer and inline separation technology, SULZER

The new Compact Mass Transfer and Inline Separation Technology (cMIST) replaces conventional Triethylene Glycol (TEG) towers and associated separator vessels to meet pipeline dewpoint specifications. cMIST achieves this goal with significant reductions in weight, footprint and cost. cMIST for dehydration is licensed to SULZER for onshore and offshore applications.

The new Compact Mass Transfer and Inline Separation Technology (cMIST) replaces conventional Triethylene Glycol (TEG) towers and associated separator vessels to meet pipeline dewpoint specifications. cMIST achieves this goal with significant reductions in weight, footprint and cost. cMIST for dehydration is licensed to SULZER for onshore and offshore applications.

BAMSE, TECHNI

BAMSE (B-Annulus Monitoring System) is a pressure and temperature sensor for installation in the B-annulus of oil and gas wells. The system uses no active electronics in the inaccessible B-annulus and is designed for life-of-well reliability.

BAMSE (B-Annulus Monitoring System) is a pressure and temperature sensor for installation in the B-annulus of oil and gas wells. The system uses no active electronics in the inaccessible B-annulus and is designed for life-of-well reliability.

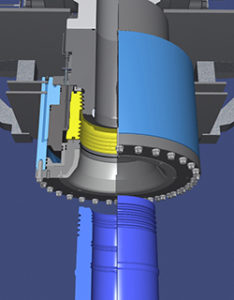

20K HPHT subsea choke, TechnipFMC

![]() The 20k HPHT subsea choke is designed to withstand life-of-field fatigue in high-pressure, high-temperature oil and gas production environments without the need for hydraulic fluids. It meets or exceeds API 17TR8. Its plug-and-cage design leverages proprietary HPHT sealing technologies and TechnipFMC’s G2i electric actuator, providing increased controllability over traditional hydraulic actuation technology.

The 20k HPHT subsea choke is designed to withstand life-of-field fatigue in high-pressure, high-temperature oil and gas production environments without the need for hydraulic fluids. It meets or exceeds API 17TR8. Its plug-and-cage design leverages proprietary HPHT sealing technologies and TechnipFMC’s G2i electric actuator, providing increased controllability over traditional hydraulic actuation technology.

Autofrac RFID-enabled stimulation system, Weatherford

The AutoFrac system enables efficient stimulation in open-hole sections of extended-reach offshore wells where traditional technologies have often failed to provide adequate reliability.

The AutoFrac system enables efficient stimulation in open-hole sections of extended-reach offshore wells where traditional technologies have often failed to provide adequate reliability.

The system enables remote operation of lower completion tools and provides several options for tool communication that do not rely on control lines or mechanical actuation.

West Drilling Products, part of West Group

The Continuous Drilling & Circulation Unit (CDU) is a fully robotized circulation unit. It is the heart of the Continuous Motion Rig (CMR) technology, offering continuous drilling operation. The CDU reduces the overall time of drilling operations by up to 50% by eliminating downhole problems associated with differential sticking and pressure fluctuations and reduces safety risk by removing all personnel from the rig floor during the drilling operation.

The Continuous Drilling & Circulation Unit (CDU) is a fully robotized circulation unit. It is the heart of the Continuous Motion Rig (CMR) technology, offering continuous drilling operation. The CDU reduces the overall time of drilling operations by up to 50% by eliminating downhole problems associated with differential sticking and pressure fluctuations and reduces safety risk by removing all personnel from the rig floor during the drilling operation.

Deeprange plug & abandonment tool, Wild Well Control

The DeepRange intervention tool delivers a plug-and-abandonment solution in a riserless package. The ROV-driven technology offers a minimally invasive solution that maintains wellbore integrity while providing cost effectiveness.

The DeepRange intervention tool delivers a plug-and-abandonment solution in a riserless package. The ROV-driven technology offers a minimally invasive solution that maintains wellbore integrity while providing cost effectiveness.

Torden high power pinless subsea connector, WISUB

The Torden High Power Pinless Subsea Connector is a next-generation product developed in collaboration with National Oilwell Varco to increase connection reliability between BOP and LMRP. This innovation is further standardizing AUV and ROV connections, combining patented high-speed data transfer with highly compact resonant power transfer. Torden delivers improved mating tolerances and reliability.

The Torden High Power Pinless Subsea Connector is a next-generation product developed in collaboration with National Oilwell Varco to increase connection reliability between BOP and LMRP. This innovation is further standardizing AUV and ROV connections, combining patented high-speed data transfer with highly compact resonant power transfer. Torden delivers improved mating tolerances and reliability.