Drilling & Completion Tech Digest

Field tests completed on Haynesville well pads using MQTT protocol for better fracking data management

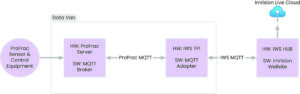

Intelligent Wellhead Systems (IWS) and ProFrac recently completed the first successful field tests utilizing the Message Queuing Telemetry Transport (MQTT) protocol for the safe and efficient transfer and visualization of wellsite data during hydraulic fracturing operations. The solution was developed in collaboration with an operator in the Haynesville.

“Currently, wellsite data is transmitted during fracturing operations by a standard communications cable using CSV (Comma Separated Value) protocol. While this method is robust, it is quite limited in what it can do, particularly with changes in the data being transmitted,” said Bob Duncan, IWS Vice President of Product Strategy. “A better solution is MQTT, a modern communication protocol that allows more data information than standard CSV protocol. Metadata, including the channel name for each data curve, can now be sent. Instead of mapping just the serial order of data, the data channel name can now be mapped, as well.”

The biggest drawbacks with the traditional method are typically the result of manual data entry. In addition, data is not sent at the start of the stage, and channels are not in the right order during setup. The new protocol takes these variables out of the equation. The burden of channel mapping and data manipulation during the job is removed from the data van operator.

The MQTT protocol has been deployed on two separate two-well pads in the Haynesville and a three-well pad in West Texas. An additional three-well pad in the Haynesville is ongoing.

SLB inks long-term agreements with TotalEnergies, Aker BP to advance digital capabilities, workflows

SLB recently announced two long-term partnerships, with TotalEnergies and Aker BP, to drive digital solutions.

With TotalEnergies, the 10-year partnership will aim co-develop scalable digital solutions for enabling access to energy resources with improved performance and efficiency. The partnership establishes a flexible framework for the companies to work together on addressing key challenges across the energy value chain, including carbon capture, utilization, and sequestration (CCUS).

The companies will integrate advanced digital capabilities, including AI, with new and existing applications on SLB’s Delfi digital platform, adhering to the Open Group’s OSDU Technical Standard. SLB and TotalEnergies will combine digital and domain expertise to accelerate the development and deployment of digital solutions at scale.

“Collaboration and knowledge sharing are key for our industry to continuously develop more effective ways of unlocking energy access,” said Rakesh Jaggi, President of SLB’s Digital & Integration business. “With this visionary partnership, we’re combining the know-how and expertise of both companies to accelerate the delivery of new digital capabilities that will benefit the whole industry.”

The partnership will initially focus on subsurface digital solutions for reservoir engineering and geoscience modeling and interpretation, leveraging Delfi on-demand reservoir simulation. These processes will be accelerated and automated using AI and real-world learnings from both companies.

“Through this digital partnership we will develop cutting-edge next-generation software, digital applications and new algorithms applied to geoscience. Thanks to these innovative modeling technologies, we will not only be better able to utilize the analyses of geological reservoirs and basins in the oil and gas sector to reduce emissions but also to make further progress in geological carbon storage,” said Namita Shah, President, OneTech at TotalEnergies.

AI-driven digital platform

Under the partnership with Aker BP, the two companies aim to co-develop an AI-driven digital platform for Aker BP to accelerate innovation and deliver substantial efficiency improvements across the company’s E&P operations. The new platform will also leverage the Delfi digital platform to enable new digital solutions in the cloud.

“By co-developing AI-powered digital technologies, we will transform Aker BP’s subsurface workflows, accelerating planning cycles, increasing production and reducing costs across their entire E&P life cycle,” Mr Jaggi said. “We have made a long-term commitment with Aker BP to continuously improve the subsurface part of their platform, driving constant efficiency optimization and more sustainable energy production.”

The partners will transition Aker BP’s current application portfolio to the cloud and create one integrated platform for subsurface workflows. The high-performance computing speed of the cloud will enable the platform to leverage advanced AI and domain expertise from SLB and Aker BP to reveal new insights from previously untapped data, driving substantial efficiency and performance improvements.

“The platform we develop in partnership with SLB is a key step in realizing our strategy to build the E&P company of the future and cement our position as a digital leader,” said Per Øyvind Seljebotn, SVP Exploration & Reservoir Development, Aker BP. “Leveraging the cloud for data-driven subsurface workflows will increase efficiency and value creation, while helping to lower the environmental impact from our fields and discoveries.”

The new platform will also build on the OSDU Technical Standard and feature close integration with Microsoft’s Azure Data Manager for Energy.

“Moving to the Delfi platform is a big step forward on our data-driven journey,” said Paula Doyle, Chief Digital Officer, Aker BP.

20k technologies enabling first oil at Anchor could also unlock 2 billion bbl in GOM

Chevron started oil and gas production from the Anchor project in the deepwater US Gulf of Mexico in early August. This marks the successful delivery of high-pressure technology that is rated to safely operate at up to 20,000 psi, with reservoir depths reaching 34,000 ft below sea level.

“Application of this industry-first deepwater technology allows us to unlock previously difficult-to-access resources and will enable similar deepwater high-pressure developments for the industry,” said Nigel Hearne, Executive Vice President, Chevron Oil, Products & Gas.

The Anchor development will consist of seven subsea wells tied into the Anchor semisubmersible floating production unit (FPU), which is located in the Green Canyon area in water depths of approximately 5,000 ft. Total potentially recoverable resources from the Anchor field are estimated to be up to 440 million barrels of oil equivalent.

The Anchor FPU is Chevron’s sixth operated facility currently producing in the US Gulf of Mexico. To reduce carbon emissions, the FPU was designed as an all-electric facility with electric motors and electronic controls. Additionally, the FPU utilizes waste heat and vapor recovery units, as well as existing pipeline infrastructure to transport oil and natural gas directly to US Gulf Coast markets.

“Chevron is leading the way to unlock ultra-high-pressure reservoirs in the Inboard Paleogene, which have never been produced,” said Mfon Usoro, Principal Analyst at Wood Mackenzie. “The Inboard Paleogene will herald a new chapter in the US Gulf of Mexico. Wood Mackenzie estimates that more than 2 billion barrels of oil equivalent could be unlocked as US GOM companies continue to advance the commercialization of discoveries in the frontier play.”

She added: “Production from the Inboard Paleogene has the potential to permanently change the landscape in the US GOM. Operators expect individual wells to recover at least 30 million barrels of oil equivalent.”

Petrobras partners with GA Drilling on autonomous reeled drilling system

Petrobras and GA Drilling have entered into a technical cooperation program along with Cenpes, Petrobras’ research, development and innovation center. With GA Drilling’s downhole anchoring and drive system serving as the cornerstone, the partnership aims to develop a next-generation autonomous reeled drilling system. The goal of the collaboration is to enable deep and complex offshore wells to be drilled from a light well intervention vessel rather than a semisub or drillship, saving 30% of well construction cost.

GA Drilling’s system enables the replacement of conventional drill pipe with reeled continuous tubing, thus minimizing pipe-handling hazards, tripping times and well control risk. The new technology includes sophisticated drilling automation and control systems and real-time wireline communications to the surface that optimize and drive the drilling process downhole at the rock face.

Network upgrades set to enhance connectivity across Shelf Drilling fleet

Shelf Drilling is set to bolster its fleet of 36 jackup rigs with a hybrid network that will pave the path for more digitalization efforts and ensure seamless offshore connectivity. The first upgrade involves implementing Marlink’s software-defined network management (SD-WAN) solution, and the second upgrade includes installing the high-bandwidth, low-latency Starlink solution on selected rigs operating in the Mediterranean and the North Sea.

This initiative encompasses the addition of Low Earth orbit services, including Starlink, where regional regulations permit. The SD-WAN solution will be deployed across the Shelf Drilling fleet, optimizing and managing network traffic to ensure high throughput and low latency.

ITC Global, now a Marlink company, was awarded the first contract for communications services by Shelf Drilling in 2014. The new contract extends the relationship by three years.

Autonomous well control solution deployed on 10 wells

ADNOC recently completed the world’s first offshore deployment of RoboWell, AIQ’s AI autonomous well control solution, in operations at the offshore NASR field. RoboWell uses cloud-based AI algorithms to autonomously operate wells that self-adjust according to changing conditions. This enhances the safe operation of the well, improves efficiency, reduces the need for travel and physical interventions and minimizes emissions.

Located 130 km northwest of Abu Dhabi, NASR is a fully digital offshore field that uses a suite of technology solutions to maximize production and minimize emissions.

RoboWell has been deployed across an initial 10 wells at NASR, with further deployment of the AI solution scheduled at more than 300 wells across ADNOC’s offshore and onshore operations this year.