Bentec: Holistic considerations ensure value of top drive upgrade

By Joanne Liou, associate editor

More drilling contractors and operators are taking a holistic approach to equipment installations on existing rigs, such as for top drives. For such turnkey integration projects, careful planning is paramount, Thomas Kipker, head of product management at Bentec GmbH Drilling & Oilfield Systems, said. “The top drive is an important machine, but nowadays, the top drive influences more rig systems than in the past,” he said at the 2013 IADC Advanced Rig Technology Conference last week in Stavanger, Norway. To ensure a successful upgrade, all parties – drilling contractors, operators and equipment manufacturers – must understand more than just the top drive itself.

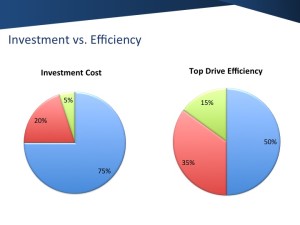

Based on cost breakdowns for nearly 60 top drive installations Bentec has performed in the past two and a half years, the company found that approximately 75% of the total investment cost goes toward the top drive unit itself. The rest is being spent on integration and personnel training, which is reflected in increased efficiency due to decreased downtime, improved rig mobilizations and fewer HSE incidents. Although the top drive itself is responsible for 50% of the increased efficiency, thorough integration can contribute more than 35% to better efficiency, Mr Kipker explained. “If you implement spending more efforts into training, it also means more efficiency.”

A good turnkey project typically begins with a rig survey to review the rig’s history. This should be conducted onsite whenever possible so that local environmental impacts can be addressed. Other details should also be noted, such as required visas and permits for personnel. “This can be addressed early and can help avoid delays at rig installation,” Mr Kipker said. Once a rig survey is complete, engineering comes into the picture for post-survey evaluation and analysis of the results.

Fit is also an important consideration for older rigs. “Sometimes a top drive does not fit in the mast top section,” for example, which then requires rearranging the top drive to avoid major modifications on the mast. Companies also need to choose between portable guide rails and fixed guide rails must in the project’s early stages. “Fixed guide rails have fewer transport units because it’s a fixed installation that does not have to be disassembled,” Mr Kipker said. “It can have faster rig moves, but you don’t have flexibility to swap top drive units to other rigs.”

Other considerations include the anti-collision system and interlocks; upgrades can help to prevent dropped objects and damage to the rig. “The top drive needs to take position of the elevator links, while the drawworks is hoisting it up, so interlocks should be installed,” he said.

It’s also necessary to factor in how the drawworks and mud pumps will work with the top drive, as they are both enabling systems. “It means that OEMs need to have more equipment knowledge, not only about the top drive but also about the other systems. They need to have interface knowledge, need to know languages and how the progress is communicated with each other,” Mr Kipker said.