As drilling complexity increases, Statoil seeks solutions in simplicity

Operator is tackling narrow drilling margins in deepwater GOM with streamlined dual-gradient system

By Linda Hsieh, Managing Editor

Uno Holm Rognli serves as Statoil’s VP of Drilling & Wells for the Gulf of Mexico.

Uno Holm Rognli serves as Statoil’s VP of Drilling & Wells for the Gulf of Mexico.

From your position at Statoil, what do you see as the most critical challenge that the industry faces in drilling and completions?

Right now the most critical challenge is not technical but commercial. It’s very expensive to drill and complete wells. We need to focus on reducing costs in order to drill more wells, to have more field developments and more production. We need to find ways to be more efficient.

How can Statoil go about increasing efficiency and lowering costs?

Although we have been able to reduce the number of drilling days in many cases, we still see struggles on the completion side. I think completions are becoming too complicated. There are many pieces of equipment that can fail. We should simplify them in order to reduce risk and reduce cost. We have to look at ways to complete the well in a different way than how it is done today – different techniques and different equipment. In the Gulf of Mexico, for example, frac packs are common. We’re working with other operators to look at different ways to simplify the process.

How can drilling contractors or other service providers contribute, as well?

I think that, as an industry, we should focus not on making things more complicated but on standardizing and simplifying things. I think everyone would benefit from that.

Do you want drilling rigs to be simplified, too? Are they getting too big and too complicated?

Drilling in ultra-deepwater, you do need significant rig capacity in terms of things like mud volumes and hookload, so I wouldn’t say that rigs are too big or too complicated. However, too often we build rigs that are supposed to do everything. At least in Norway, we’re looking at using smaller vessels to do work that you don’t really need a rig to do, such as installing the conductor casing or P&A. I think limiting the scope of the rig, which is a big cost for operators, is one possible way to go.

You said rig capacity is important in ultra-deepwater. Is water depth the main driver for your rig requirements?

Actually, water depth is not so much the driver. It’s the well design and the total depth of the well that make the requirements for the rig. When I talk about challenges in deepwater, they revolve around the drilling depth, and the pore pressure and frac gradient.

How is Statoil approaching challenges around the narrow drilling margins?

The industry has been working on dual-gradient technologies for many years, trying to find ways to manage the window between the pore pressure and frac gradient. Statoil has also been looking at different concepts that would allow us to handle the small margins.

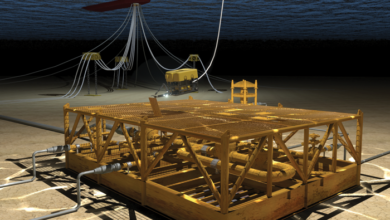

We’ve come up with a concept called ECD-Management (ECD-M). It is a controlled mud level system for controlling bottomhole pressure. By using a subsea pump module installed on the riser, we can reduce the mud level in the riser. You take the returns to the pump and up a mud return line integrated in the riser. This allows us to easily adjust the mud level in the riser, which will influence the bottomhole pressure.

There are two categories within ECD-M: CML-O and CML-U. In CML-O, the riser fluid level always ensures overbalance to the formation. In CML-U, we’re not drilling underbalanced, but the hydrostatic pressure from the mud column may not be sufficient alone.

We have seen that, closing in the well with a regular BOP, the annular typically shuts in in 45 seconds. However, we have said we need a quick closing annular contingency device so that, if we are in this mode, we could shut in the well in five seconds to trap pressure and ensure overbalance.

Do you already have this device?

The Delta Seal Riser Module (DSRM) has been designed into our system, but it has not been delivered to us yet. So we are using only CML-O at the moment, but hopefully we can go to the CML-U phase for the next well in the Gulf of Mexico. However, we will never plan to drill underbalanced. It’s only if there’s a blackout on the rig or a similar shutdown situation, then we want to have compensating equipment to handle it.

How many wells have you drilled using this system?

We have drilled one well in CML-O mode so far, and we are starting with the next one shortly. Because the DSRM still is not available to us, it means we cannot take the system to its full extent. Still, we are getting good experience.

What are the well control considerations with ECD-M?

The mud return line from the pump integrated in the riser can be isolated from the riser. If the system fails, we can just isolate it and continue drilling conventionally. If we have any well control situation, we would isolate the ECD-M equipment and close the BOP. Any well control situation would be handled conventionally; we are not dependent on the system.

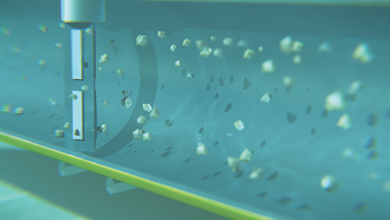

In the Gulf of Mexico, we have focused very much on well control, well integrity and being able to monitor the well to detect kicks early. When you stop the pumps, typically 50 to 70 barrels will flow back to the rig before you can see if it levels off, and that takes minutes. We want to do better than that, so we have implemented a smart flowback fingerprinting system to monitor connections.

We have also implemented a system with a Coriolis flow meter. This allows us to see small-volume increases and, therefore, detect kicks early. This early kick detection system has already proven very accurate. With ECD-M we have two new kick indicators – the riser pressure and the subsea pump speed. Several kick drills conducted during the first well have proven that these offer even earlier kick detection than the Coriolis, and we have called this instant kick detection.

Has Statoil used ECD-M only in the Gulf of Mexico?

We did a pilot test on the Troll field in Norway with the subsea pump system before using it in the Gulf. Now they are starting it up again on Troll, although they have a different application. In Norway, they are drilling into depleted reservoirs so they need to have a lower mud weight than they can normally get with water-based mud. But they don’t want to go to oil-based mud due to its environmental implications. This system allows them to drill longer wells than they normally could.

How receptive have regulators like the US Bureau of Safety and Environmental Enforcement (BSEE) been to innovative systems such as ECD-M, which allows for safer drilling but involves a different way of thinking and working?

We have worked very well with BSEE, bringing them into the discussion early, giving them reports at certain milestones and meeting with them to keep them updated. I find that they mainly have two questions. First, with other dual-gradient systems, the business case is to change the well design to leave out casing strings and drill longer sections; that is where they save money. So BSEE has been asking if ECD-M will change our well design. Our answer is no – we will design our wells so they can also be drilled conventionally.

The other question they have been asking is about well control and whether we have to use the ECD-M system if we get into a well control situation. As we discussed earlier, the answer is no. If we get into a well control situation, we will isolate the system and handle well control conventionally.

I think there is still some skepticism about new technology and what can go wrong. But we have tried to focus on the simplicity of our system and the fact that, if it fails, we can isolate it.

How else is Statoil working to improve the efficiency of its drilling operations?

Technology is often about developing new pieces of equipment, but there are also different ways of working and different ways of bringing knowledge together that are very important. Sometimes that’s even more important than the tools you have.

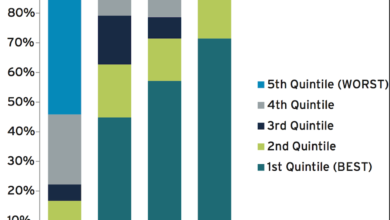

Statoil uses what we call the Perfect Well concept to look at how efficiently we can drill our wells. If we do the best we have ever done, what would the well look like? Then we plan for that.

So it’s an optimization process?

Yes, but it focuses on the planning stage. I compare it to ski jumping. The preparation, training and getting into the right mindset – you have to do all that before you start. When you are mid-air, it is too late. Perfect Well is what we do before we actually start. Because when we are actually in operation, the design is done and the equipment is ordered, then you can only do so much to optimize things. It’s the process before the jump when you can actually make the big difference.

Often when the industry talks about drilling automation, they’re still really talking about mechanization. However, it appears that we are getting closer to closed-loop drilling using algorithms guided by real-time downhole feedback. Do you see this approach playing a significant role in the future of drilling?

I do. In fact, we are using algorithms in the ECD-M control system, where control of the pump is done more or less automatically based on readings and so on. We’re also using a lot of simulations to predict what’s going to happen. We still have a person who actually presses a button or pulls a stick, so it’s not automated yet, but we have to learn how to use automation and respond.

I know that some people have visions of taking people completely away from the rig floor, but I don’t think we will go there. I think we still depend on people to control processes, and we still need people to make decisions. And if the human tries to do the wrong thing, the system will actually stop you. “Are you sure that you want to press this button because this and this will happen?”

Statoil has an automation program that we are implementing on fixed installations in the North Sea to take this a step further. We call it intelligent well construction. I think we’re getting there, but we still have a way to go.

What would you like drilling contractors to be thinking about when they consider the future of drilling?

I think drilling contractors should look at what other types of services they can integrate into the rig and deliver as an integrated service. It could be a different type of drilling like the ECD-M.

It took us nearly two years to build and deliver the ECD-M system onto the Maersk Developer. My vision is that this type of service will be included in the rig package in the future. When we contract the rig, it will come with it.

Some contractors are very eager to look at the different systems available, and I think that’s the way to go. They can really distinguish themselves if they can provide this type of service as an integrated part of the rig.