A brief history: the evolution of human factors, human performance

Understanding the origins of these terms can help the drilling industry to more effectively apply underlying principles to improve safety performance

By Marcin Nazaruk, Baker Hughes, a GE company

In the July/August 2019 issue of this magazine, an article discussed the Human Performance on Oil Rigs Workshop, which highlighted how important human factors (HF) have become in the drilling industry. This article aims to provide background on how the recognition of human factors has evolved to its current stage.

History of Human Factors

The beginnings of human performance (HP) can be traced back to 1898. Frederick W. Taylor – a mechanical engineer who has been called the father of scientific management – modified the way workers completed their tasks at Bethlehem Steel by providing customized tools. These user-centered designs resulted in a threefold increase in daily output.

He also modified selection, human factors training and work-rest schedules using data collection and statistical analysis.

The early 1900s was a period when psychology was dynamically growing as a discipline. Flying aptitude tests were first developed for the US Army, with other efforts focused on improving selection and training. The focus later shifted from pilots to aircraft design, examining the impact of controls, displays and G-forces on pilots’ decisions and behaviors.

Developed in 1937, the first G-suit was a product of research on human and machine thresholds of performance. The Second World War accelerated the application of psychological research in high-risk activities.

By looking at both the mental and physical needs of end users, it led to better designs. For example, radar controls and displays allowed for more effective recognition of enemy aircraft. Solving such challenges required engineers to work closely with psychologists.

Although the military sponsored almost all HF research during the war, the civilian industry later also became interested in its value. McDonnell Douglas and Boeing both established HF teams, and Bell Laboratories created an HF group that advised engineers on the layout of keys for telephone handsets.

During this time, many industries began to realize that the increased effectiveness of reaching desired goals does not depend on the human or the technology alone. Rather, it depends on how well the person, the machine and the process interact together to create a system. HF professionals focus on this system, not the human or machine separately.

This requires a multidisciplinary approach, including medicine, physiology, engineering, computer sciences, statistics and psychology.

A similar evolution of application of psychology into military and industrial domains occurred in the United Kingdom and Russia. Those efforts led to establishing professional bodies for HF practitioners, such as the UK Chartered Institute of Ergonomics and Human Factors (1949) or the US Human Factors and Ergonomics Society (1957).

Key questions that have been examined include:

• What factors increase the likelihood of human error?

• How can procedures and work instructions be written to make them easy to understand and reduce the likelihood of mistakes?

• How can tools, equipment, workstations or facilities be designed to reduce chances of human error?

• How can behavior during incident investigations be explained to account for the influence of the system?

Human Performance Principles

The HP discipline evolved in parallel to HF. A prominent influence was a Harvard psychology professor named B.F. Skinner, who is known as the father of behaviorism. Around 1954, he laid the scientific foundations for the Behavior-Based Safety and ABC model (Antecedents/Behaviors/Consequences).

According to this model, the consequence that follows behavior has the biggest impact on the likelihood of similar behavior occurring in the future.

He developed a teaching machine that allowed learning by offering a multiple-choice test with a twist. Students would receive feedback (consequence) immediately after providing their answers. In the 1960s, this “programmed instruction” was applied in military training and reduced the time needed to master a subject by a third.

Based on such successes, the National Society for Programmed Instruction (NSPI) was formed in 1962. The focus was initially on education but over time expanded to business applications.

The NSPI changed its name in 1995 to the International Society for Performance Improvement.

Robert Mager, one of the presidents of the NSPI, said, “People often don’t do what they know how to do because of the following reasons:

- They don’t have the tools to perform as desired;

- They aren’t given the authority to perform as desired;

- They don’t know what they are expected to do; and

- They are punished for performing as desired.”

In the 1970s, a student of Professor Skinner’s, Thomas Gilbert, outlined how to describe and analyze HP. He identified six categories needed to determine why somebody may not be performing well in their job and called it “Behavior Engineering Model.”

Gilbert’s Behavioral Engineering Model

- Expectations, information available, & feedback

- Support, tools, & resources

- Consequences & incentives

- Skills & knowledge

- Selection & capability

- Attitude & motivation

Rummler-Brache Human Performance Improvement Model

Another milestone in the HP field was the work of Geary Rummler and Alan Brache – pioneers in the application of instructional and performance technologies to organizations who recognized that in order to explain behavior accurately, one needs to think of the broader organization. This is called systems thinking, and the core belief is that every individual operates within the context of the system. Improvements are only possible if we understand the system.

According to Mr Rummler and Mr Brache, “most attempts to improve human performance are doomed to failure from the start … because they proceed from the fundamentally flawed assumption that people perform in a vacuum.”

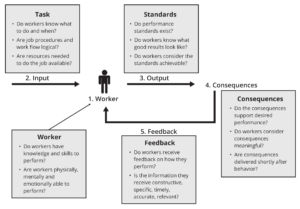

Figure 1 illustrates the various aspects of the system to consider in understanding and driving desired human performance.

Mr Rummler offered the following 3 principles regarding the model

3 Phases of Rummler’s Process Improvement Methodology:

- Desired performance is a result of all five factors (the worker, the task, standards, consequences and feedback)

- The cause of poor performance is rarely the lack of skills

- Knowledge/skill has little leverage

He held that “instruction or training alone cannot overcome the predominant forces of task, negative consequences, or lack of feedback that are firmly embedded in some organizations.” In his words, “if you put a good performer against a bad system, the system will win every time.”

To help leaders make sense of this, some major oil and gas operators have adopted a version of HP principles. One version reported by Todd Conklin of Los Alamos National Laboratory is this:

- People make mistakes.

- People’s actions are rarely malicious but are usually well-meaning behaviors intended to get the job done.

- Unexpected events may be a symptom of a weakness in our systems.

- We can detect, manage and prevent most error-likely situations.

- Understanding the context surrounding error and implementing defenses based upon learning can help reduce the severity of incidents.

- Organizations and leaders influence individual behavior.

- How leaders respond to failure matters; suspend judgement and respond with curiosity.

Embracing HP principles allows shifting the focus from a person to a system and developing better preventive/corrective actions.

Summary

Both HF and HP are technical disciplines where experts are expected to have HF/HP-specific education and broad practical experience in analyzing and improving factors that shape human performance.

One of the big implications of HF/HP insights is that asking why – in order to explain behavior, e.g. “why did they do this?” – is not very effective.

It is rare that there is a single reason identified for a behavior. Additionally, even if we asked why five times, it still would not help because behavior does not have a “root cause.”

“If you put a good performer against a bad system, the system will win every time.”

Instead, behavior is a result of the interaction over time between a person, task and machine or process, which includes input, output, consequences and feedback. These, in turn, are created by a broader set of organizational factors.

When you face a problem with behavior on the job, you might start by asking questions that are suggested in Figure 1. They could help you to find out how those different factors play a role. DC