Digital technologies support new workflows in drill bit forensics

AI and machine learning allow for dull wear data to be easily collected, digitized and analyzed, leading to better bit designs, optimized drilling

By Stephen Forrester, Contributor

Among the equipment and technology necessary to drill a well, the drill bit is arguably the most critical piece of the puzzle. Bit design, a fast-paced world of iterative enhancements and improvements that enable wells to be drilled more rapidly and efficiently, considers many downhole factors—geology, lithology, wellbore geometry, potential interactions with the bottomhole assembly (BHA)—as specialized engineers seek to develop bits that can overcome the challenges inherent in today’s more complex wells.

While drill bits may be the metaphorical tip of the spear, the process of grading their condition after a run has seen limited changes over time. Typically, rig crews perform onsite analysis of the bit, taking photographs of its condition and assigning it a dull grade based on industry-accepted methodology. However, this process can be time-consuming and fraught with human error and inconsistency. To advance drill bit design in line with the industry’s desire to digitize and automate processes, several companies have developed new technologies that augment or replace previous methods.

Automated digital dull grading

Dustin Lyles, Vice President of Technology for Taurex Drill Bits, said the industry has to advance beyond archaic methods for dull grading of PDC bits.

“The best insight that we have into what’s going on in that rock-to-bit interaction that’s occurring miles below the earth’s surface is that dull drill bit that comes back out,” he explained. “That’s a fingerprint of what type of drilling dysfunctions and environment the drill bit is seeing while downhole, and being able to analyze that bit is what gives us insight to produce our digital workflow and feedback system.”

Knowing that there is intrinsic value in a drill bit is one thing, but obtaining actionable data is another. Digitizing bit condition data so it can be used across every drill bit design decision Taurex makes has been key, Mr Lyles said. Drilling and highly detailed dull data is fragmented in nature. Runs might be captured for projects with one specific operator and/or bit part number in Delaware Basin Wolfcamp B laterals, for example, and decisions made relative to necessary actions to improve performance within that narrow scope. Taurex, however, believes that understanding the correlative relationship among drill bit design, wear and application is critical to making more holistic design decisions. To accomplish this, the company produced a digital dull analysis model/workflow, which leads into forensic analysis and root cause failure analysis on a large-scale basis.

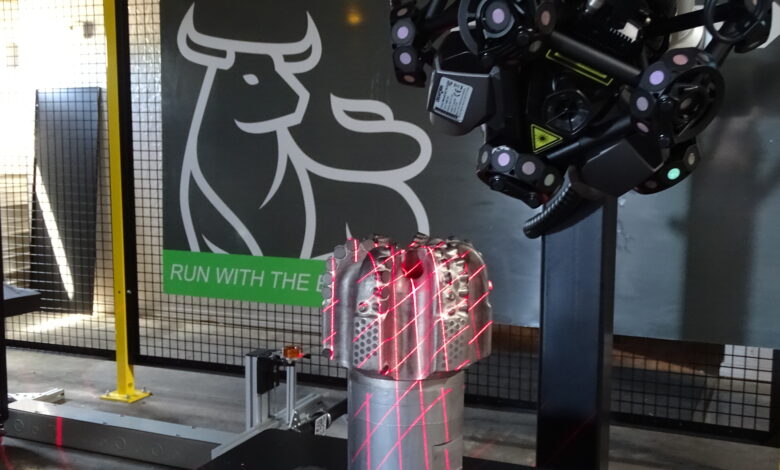

The Automated Metrology Laboratory (AML) is the company’s innovation in automated digital dull grading. Deployed at the company’s central repair and maintenance facility, every drill bit that it runs goes through an automated, 3D, robotic scanning procedure. Within three to four minutes, Mr Lyles said, that scan is pushed to a remote server, allowing engineers to access and quantify the amount of diamond loss on every individual cutter on that bit. “Data from the initial AML analysis on each drill bit is pushed into a relational database to tether dull trends with application, design, electronic drilling recorder (EDR) and other relevant data sets necessary to put the pieces of the puzzle together,” he noted. “Then, we can paint a picture about what type of drilling dysfunction occurred, or what was the driving factor behind the wear and tear seen on the drill bit.”

The issue plaguing the industry is not a lack of trained engineers with the skills and mechanical means to evaluate a drill bit. Instead, it is the fact that there is too much subjectivity and inconsistency in the process. “Our measurement system for evaluating diamond loss is accurate down to three-thousandths of an inch,” Mr Lyles said. “We know that it is extremely accurate and consistent across every bit that we run, and evaluating trends with that system provides insight into our bit design and how we overcome challenges in today’s drilling environments.”

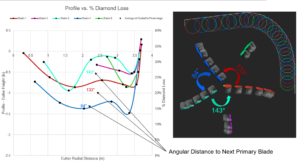

Understanding the complex relationships between back rake angle, side rake angle, axial force and tangential force versus cutter damage, which vary across every single bit design, allows for improvements to drilling performance and reductions in the wear sustained on a given bit.

Cutter testing and development plays a critical role in advancing drill bit performance. By having these types of data sets available, Taurex can work directly with cutter manufacturers to drive enhancements to their designs before they even leave the lab. Traditionally, these manufacturers have not had a true feedback system providing insights from the end user. With the detailed data coming out of AML, however, these same companies now have access to the information they need to drive better decision making in their own design processes, leading to better cutters being implemented in drill bit design across the industry.

“By application, the manufacturers can now go in and do their own statistical analyses based on the cutter grade run so that they can start to better understand and correlate cutter performance to real-life field applications, on a large-scale basis,” Mr Lyles explained.

There is also the issue of how long it takes for individual human beings to perform drill bit analyses. A process of mechanical measurements would typically require several hours for an engineer to complete, but AML can now complete the task – with improved accuracy and precision– in only a few minutes. This provides Taurex with the ability to drive iterative improvements to bit design at a much more rapid pace than previously possible, especially when multiplied across hundreds of bits.

“Data we get from AML can be used the same day on repairs going on in our shop,” Mr Lyles noted. “We need to have that data at our fingertips. It’s all about empowering us to make better decisions, and it really does come down to speed, which is why we automated as much of the process as we could.”

Within 15 minutes — three to four for the scan and 12 to get everything uploaded to the database — Taurex engineers can access live data on every bit, tracking information on which cutters are performing best in which positions and which designs might have a higher damaged-beyond-repair frequency or higher rate of failure on a specific portion of the drill bit, Mr Lyles said.

“Data democratization is a really critical component of what we do, and something we’ve spent a lot of time on,” he concluded. “You can’t automate producing an optimized drill bit, but you can automate a lot of that analysis and evaluation methodology. You still need engineers, and you still need contextual domain knowledge to interpret the data — at least until we can use machine learning to build models. That might not be as far away as you think.”

Digital dull analytics and in-bit sensors

Chris Propes, Strategic Business Manager for Halliburton Drill Bits and Services, said that drill bit forensics are key to how the company does business. “It involves analyzing the dull condition of the bit and combining that data with information we know about the run to develop solutions that improve drilling performance,” he explained.

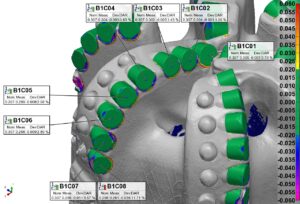

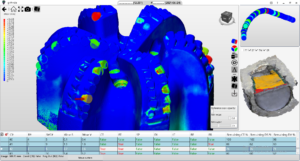

One technology Halliburton uses as part of its bit forensics program, Oculus, is a big data analytics platform that takes 3D scans of every drill bit the company runs and uploads them into a database. This provides insight into cutter and bit-body condition in every market in which it operates. The massive amount of information coming in, Mr Propes said, must be understood before it can become actionable.

“What we’ve done is built internal design platforms that allow us to search down to a specific application — whether an intermediate section in the Permian or a drill-out run offshore — and narrow our scope down to extract all of that forensic information for that application,” he noted. “That includes dull analytics from Oculus data, photography and downhole performance data. Having all that made it possible to build visualizations that help design engineers make trade-offs to optimize bit design for those applications.”

The sheer number of bits that go into Halliburton’s repair and maintenance facilities on any given day is actually an advantage when paired with a system like Oculus. “Every service center is set up with Oculus,” Mr Propes said. “So, when a bit comes back to the facility post-run, the first step of the cycle is to scan it with Oculus to capture that forensic data.”

It is not enough, though, to simply obtain information on the dull grade. Instead, forensic data from Oculus must be correlated with design characteristics — the cutters being run, the back rakes being run, and so forth — so that design decisions can be tied to the advanced forensics analysis to make meaningful improvements. Halliburton, Mr Propes noted, approached this process in a systematic way.

“When you think historically about how you design a bit, you would get offsets from three or four runs, you would look at photographs and determine if there was impact damage or abrasion, and then you would make decisions based on that, but you’d be isolated with those designs,” he explained. “The key enabler we’re seeing gain traction is that, although we can still look at those three offsets in fine detail, we can now enhance decision making using data from 100 offsets or 1,000 offsets — whatever we filter to be relevant. It’s about making data-driven decisions versus intuition-driven decisions, and we’ve moved our whole design philosophy in that direction.”

Cutter development is the other area in which Oculus provides quantifiable improvement. With Halliburton running thousands of cutters, a system that allows the company to compare cutter performance in a manner that is analytical instead of anecdotal has driven a step-change in how it interfaces with cutter manufacturers.

“In collaboration with the cutter manufacturers, we have a robust understanding of the levers of PDC diamond — grain size, pressure, leech and all the other variables that go into making different types of cutters,” he said. “The additional value we bring is a high-level understanding of dull condition, so we can provide data on the cutters relative to the downhole environment and determine what levers we need to pull to solve specific challenges. The advent of data in those discussions has been beneficial by taking subjectivity out of the equation.”

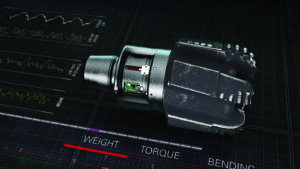

Another technology critical to Halliburton’s drill bit forensics program is the Cerebro in-bit sensor package. The sensors capture downhole data, including lateral and axial vibration, torsional resonance, whirl and stick-slip, while an upgraded version also captures data on weight, torque and bending measurements. Understanding the drilling environment with data about downhole conditions and phenomena coming directly from the drill bit makes it possible to determine why the damage noted by Oculus occurred in the first place.

“We want to combine data-driven dull analytics and in-bit sensing with advanced bit technologies and cutters to bring everything together through our design interface,” Mr Propes said. “We want to take all that information and efficiently integrate it into a bit design that will consistently outperform whatever the baseline target is. Historically that’s been an SME-driven, one-off process. Now, with automated systems, we can make it more repeatable and consistent to extract performance out of our designs through data.”

Instead of basing decisions on limited, often anecdotal pieces of information, companies that use technologies like Oculus and Cerebro are able to more precisely understand cutter failure mechanisms and downhole drilling environments. Advanced dull analytics and depth-based run data come together to provide a much clearer picture of what happened to the bit, enabling superior solutions that ultimately result in drilling performance improvements.

Autonomous bit dull forensic digitization system

While some bit forensics solutions focus on technology in a lab, Trax Electronics has a system that can be used either in a shop, lab or at the rig site. Called grA+de, the autonomous dull bit forensic digitization system can be used immediately after a run. The goal is to eliminate the inherent inconsistency and unreliability in human interpretation, while also freeing up engineers to focus on other critical tasks.

Before such technology was available, laboratory staff would manually sift through and analyze post-run data. This was always a laborious task, made more daunting by variation in the quality of data from the field. Due to the discrepancy in the type and quality of data coming in, aggregation of the information into an analytical software package for diagnosis was difficult. Furthermore, attempting to overlay this data with relevant drilling parameters to truly assess bit performance was extremely challenging, if not impossible.

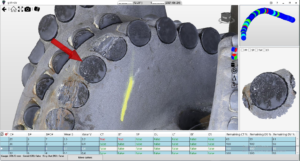

“We wanted to build a machine that could be easily operated by someone with minimal training in a shop, at a lab, at a rig site, or potentially anywhere, and reliably build a 3D visualization,” said Ron Schmitz, Executive Advisor at Trax. “We use photogrammetry, which is basically taking photographs from various perspectives around the bit, and build a visualization with that.”

Robotic-controlled, AI-enhanced photogrammetry, or the science of making measurements from photographs, is at the core of the system. The user places the bit within the scanner, a roughly 4-ft cube, and lets the system get to work, with a camera taking pictures automatically at all relevant angles.

Once those images are input, the output is typically a point cloud map, which is a drawing, measurement or 3D visualization of some real-world object or scene. The scan takes approximately 15 to 20 minutes depending on the size of the bit, while it takes approximately 90 minutes for the AI to compute the dull bit forensic characteristics. By leveraging and applying this technology to dull bit grading, the system produces highly accurate and repeatable measurements of individual cutter wear in PDC bits, as well as machine-generated base parameters for the IADC dull bit grading protocol.

Trax says it sees quantifiable value in having its system on a rig, in a shop or in a lab. “We feel that there’s a big advantage in being able to obtain an independent analysis from a third party,” Mr Schmitz said. “There are also time and cost factors; since we can provide photographs on site, at a lab or in a shop, you can view the visualization in a few hours. It may not help you decide which bit to run, but it could help you decide that you want to vary drilling parameters to avoid some of the damage you saw in the scan.”

The point of collecting this data is not simply to understand what happened to the bit, of course, but also to use the data to optimize drilling. By obtaining reliable, independent cutter-by-cutter forensics, Trax sees five key areas of bit forensics that will enable better drilling performance.

First, companies can improve bit design and quality control, enabling better operator/vendor collaboration and potentially enhancing drilling and directional performance, particularly in unconventional wells that are longer and more complex. Then, drilling dysfunctions can be identified to eliminate cutter damage, ultimately prolonging bit and BHA life and reducing the time needed for tripping.

Next, bit wear can be managed, which Mr Schmitz said is critical. “There are a lot of issues around bit wear instead of bit damage,” he explained. “For example, looking at where the cutter is located on the bit and if it’s spalled, chipped or broken, people can get a good idea of what was going on downhole to cause that damage.” He also noted that often, pulling a bit with no or only “smooth” cutter wear may not be optimum, as this could indicate that performance wasn’t maximized. Being able to assess smooth wear down to “sub-0” levels could be very important in some applications, as that could mean higher ROP could be achieved without causing damage. Less wear does not necessarily mean an optimum run.

The fourth area is increasing data granularity to make big data analytics possible. “A typical dull code involves an overall average for the bit as a whole,” Mr Schmitz said. “The new protocol being considered by the IADC has information across all the cutters on every blade, distinguishing if the damage is in the cone, nose or shoulder, how much is the loss area, and what kind of damage occurred.” The next step, which could be enabled via Trax’s bit forensics, is an even more detailed analysis on a per-cutter basis, down to the wear or damage seen at a micro level.

The final objective is to improve overall quality assurance, which is critical in iterative bit design improvements. “When we analyzed one bit with a depth-of-cut (DOC) limiter, for example, we noted a difference in the visualization between what it was supposed to be and what it actually was,” Mr Schmitz noted. “When we’re talking about the very precise designs that they’re trying to develop now, in terms of limiting the DOC to exactly what they want in order to avoid damage while maximizing DOC to drill as fast as possible, differences of that magnitude start to become important.”

Drill bit failure forensics using field photography

Drill bit forensics is also a topic of study in the world of academia. An ongoing research initiative at the University of Texas (UT) at Austin involves the development of a software algorithm that can automatically analyze photos taken of the bit at the rig site and identify, from those photos, the root cause of bit damage and failure. The goal of the project is for the software to be able to accurately evaluate a used bit so that changes can potentially be made to the BHA and/or bit before the next run.

The methodology for this automated forensics process involves four steps. First, the algorithm is given a set of drill bit photographs that clearly show individual blades, allowing the software to identify all the cutters on that bit. The software then quantifies the damage to each cutter, drawing on a database of surface sensor and downhole vibration data, as well as offset well rock strength information, to characterize drilling dysfunction relative to the damage seen on the bit. After calculating cutter location, the software then uses a classifier to determine the average damage in various parts of the blades, thereby enabling it to infer the root cause of damage.

Jian Chu, a PhD student working on bit forensics research, explained that the initiative continues to advance. Previous versions of the software were not always able to detect all the cutters based on the photographs available and lacked precision. Additionally, not all damage could be calculated, and when it was, it was only quantified as a whole number. Further, the algorithm was affected by lighting, and the forensics process did not include EDR data. However, the team is now focusing on identifying the damage type (such as worn, chipped) and improving the precision of damage grading via semantic segmentation.

Mr Chu said it was critical that noise from the drilling environment is removed in order to develop something truly useful. “One big issue we had is that we didn’t have a lot of data,” he explained. “For traditional machine learning algorithms, they would need millions of data points to train the neural network. We didn’t have that much data, so we had to remove all the noise and really focus on what we had.”

Through precise area isolation, damage categories identification and integration of expert systems, the process will eventually be entirely automated, with the algorithm becoming more and more accurate. Since the photography used to drive the algorithm is still prone to human error, Mr Chu said that maybe one day, computer vision on the rig floor could take photographs of the bit as the BHA is pulled, capturing all angles and feeding that data to the algorithm.

There is additional potential should a company choose to develop an application for the algorithm that could be deployed on a smartphone or tablet, which would make the process even easier and reduce the concerns associated with limited connectivity on remote sites. For now, Mr Chu said he isn’t worried about the commercial potential of the platform. He is more interested in advancing the field of drill bit forensics: “I want to make something useful for the industry.” DC