Online structure keeps training job-specific

Competency-based e-learning modules fast-track employee development, verification process

By Klaus Rimke, Newsco International Energy Services

Understanding the terms “competent” and “competency assessment” are integral to any safety program, as both terms are being used with increasing frequency within the context of occupational health and safety (OHS).

Legally, it is the employer’s responsibility to demonstrate its due diligence to appropriately train all employees. Therefore, it is integral that employers can demonstrate the competency of its employees.

In case of an OHS incident, if it cannot be proven that a worker was competent or that everything “reasonably practicable” was done to ensure a worker’s competence, the organization may be charged and held liable.

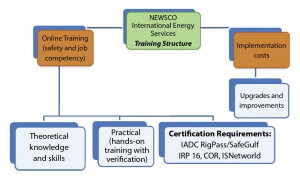

In 2008, Newsco International Energy Services implemented an e-learning approach to meet and exceed regulatory requirements, which has proven beneficial in controlling compliance requirements and improving both service quality and the corporate safety record. Competency-based operating training modules were developed and integrated with applicable OHS programs, allowing for significant expedition of the training and verification process for employees. This approach included the ability to track and verify both theoretical and practical comprehension.

In the oil and gas industry, many service companies are not regulated by set standards as found in the automotive, construction and medical fields, where government standards with approved training curriculums are established through colleges and universities issuing licenses and diplomas. A comprehensive apprenticeship for the company-specific job descriptions was therefore required to assist Newsco in meeting the following goals:

• Online certification for IADC Rig Pass and Safe Gulf for its global operations;

• 100% compliance with all owner clients in ISNetworld;

• Exceeding certificate of recognition by maintaining a mean audit score of over 90%;

• Meet all requirements for Industry Recommended Practices (IRP-16); and

• Leading industry standards for measurement while drilling (MWD) operators, directional drillers, lab technicians and office personnel.

Task hazard assessments

Breaking down the business model into independent tasks to build task hazard assessments or JSAs that apply to each and every job description is a daunting task. As a starting point, the following eight areas must be addressed and documented:

• Evaluation of all equipment, machinery, work areas and work processes to identify and analyze all potential sources of harm to workers;

• Control measures, including engineering controls, administrative controls and personal protective equipment;

• Commitment from senior management to stand behind the health and safety management system is essential for its success;

• Workers need to know how to do their jobs safely without putting themselves or others at risk; new and/or young workers require special attention;

• Regularly scheduled inspections are an opportunity to identify any hazards that have not yet been recognized and to verify that existing hazard controls are working;

• Emergencies could include natural or manmade disasters, as well as health emergencies or injuries. Effective plans need to be in place to address all potential emergencies;

• When an incident occurs at any workplace, carrying out an investigation is important so that any inadequately controlled hazards are identified and controlled, and processes can be put in place to prevent recurrence; and

• Program administration ensures that all parts of a health and safety management system are properly looked after and communicated to employees.

At Newsco, these processes have been in place for four years and have helped improve the companywide safety and training culture. Once identified, hazards and skills/tasks requirements will become the basis of an online program. Each employee is unique in how they absorb and retain information; therefore, a successful online e-learning system will incorporate multiple methods of training mediums to distribute and document the program.

The breakdown

All training courses should be broken down into competency-based training modules that are grouped by graduated levels of accomplishments, allowing the trainer to identify specific areas of weakness through the use of the test scores. Once weak areas are identified, one-on-one or supervised specific training sessions can be developed to enhance those areas or correct any hazard controls that are found deficient.

Safety training is not isolated from job-specific training as all tasks and skills require a safety component to perform the job skill set required. The program should also be allowed to naturally evolve and can be expanded through video and multimedia links to enhance the training and subject comprehension of the employee.

Focus will remain on each identified competency, as the program will turn into a living document that requires control. Data and reports that can be provided will assist in proving the system’s worth. Employing these techniques will result in significant reduction of injuries, operator errors, downtime and associated costs to the client. As a result, this will equate to reduced worker compensation payments and recordable incidents.

Housing the data

A learning management system (LMS) can be used as an e-learning platform to house and allow access from anywhere in the world, in addition to tracking the training schedules and achievements or failures of each employee within the company. Failures can be used to aid the employee by identifying areas that require improvement.

Using a digital LMS also makes the updating and addition of courses manageable, without the costs of continuous reprinting of changing safety, operator and maintenance manuals. Printed reference material or operational check lists are still required and can be added to the reference section of the LMS for an easily accessible document that’s modifiable and up to date.

This process will aid in documentation and version control throughout the company, ensuring that all employees access the same current information, which will set a higher standard of consistency in the processes and procedures outlined.

Companywide compliance is managed through email or direct contact with the employee to ensure they are continually informed on new or modified course loads and compliant with changing rules and regulations in a documentable format. Depending on the LMS used, the system can also be set up to automatically add new or modified courses available in the system, inform employees of the new courses and follow their progression to completion.

Building TLM database process

As stated, before putting a system together, the trainer must examine each job description by task and necessary skills by a predetermined level requirement. Once the basic structure is determined, a lesson plan for each skill/task can be generated in print or video, specifically documenting that training agenda.

These lessons are then grouped into a training module to cover the theoretical information being instructed, and a question base is added to test each module covering the theoretical knowledge and retention of the employee. This ensures there are enough questions in the database to verify that the main points are covered and that a random number of questions can be drawn upon to allow for variation of each test to assure multiple test accuracy.

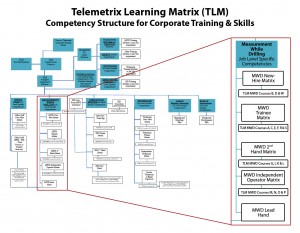

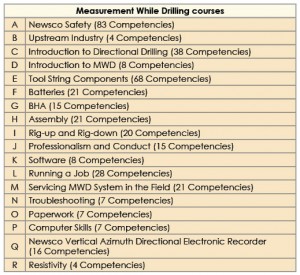

Newsco uses a structured safety and training program called Telemetrix Learning Matrix (TLM), where the MWD database contains 391 competencies with more than 5,000 questions. This specific area was broken down into five specific job levels, with each job description requiring specific courses (Table 1).

The courses are broken down into job-specific modules so students are not overwhelmed with too much information at one time. The theoretical training can then be combined with a practical verification process in the shop and in the field.

The implemented matrix assigns specific job and safety competencies to each employee by job and experience level, with only the courses that apply to that specific job level being assigned and reviewed by the employee until completion.

Once theoretical and practical compliance have been achieved, additional courses are assigned to further the employee’s advancement and knowledge.

These courses can be done in the field as long as an Internet connection is available. A qualified lead hand should also be on location to observe and provide the practical supervision in the following three steps:

• Demonstrate task/skill to employee/trainee;

• Have employee/trainee demonstrate the task/skill to the lead hand (supervised practice); and

• Verify compliance and understanding through a documented practical demonstration.

To meet and exceed any regulatory requirement requires proof of compliance through documentation and demonstration of commitment from the entire company. This cannot be done through the use of e-learning or hands-on training alone but requires a change in the safety culture within the company and the industry itself.

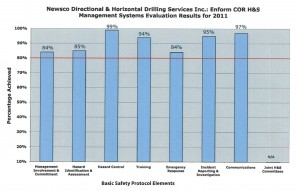

Newsco maintained a three year average of above 92% compliance in meeting regulatory requirements through its continuous goal of documentation and verification of all work-related tasks and procedures.

The data compiled from each audit and total recordable rates will fluctuate as this dynamic program is developed. The amount of resources applied and extent of employee compliance will determine how the program is introduced to the work force. Therefore, effective communication is paramount in establishing a workable e-learning program that meets and exceeds all associated regulatory requirements.

This article is based on a presentation at the 2012 IADC Health, Safety, Environment & Training Conference & Exhibition, 7-8 February, Houston.