Supercomputers and CCS key to Petrobras’ efforts to build a low-carbon energy ecosystem

NOC relying on powerful data processing to reduce number of wells drilled while seeking regulatory support to develop industrial CCS

By Stephen Whitfield, Associate Editor

Meeting the demands of the energy transition will require operators both to adopt new technologies that can improve efficiency in oil and gas E&P and to deploy low-carbon solutions like carbon capture and storage (CCS).

Petrobras is aiming to reduce its environmental impact by combining low-carbon energy development with computing systems designed to reduce geological uncertainties in exploration and, thus, reduce the number of wells needed to develop new fields. This will lead to significant cuts in emissions while enabling increased efficiencies, which will allow the company to continue exploring new offshore frontiers, said Joelson Mendes, E&P Executive Director at Petrobras.

“In our vision, oil and gas is an enabler of the low-carbon economy,” Mr Mendes said. “We’re revisiting our strategy and bringing light to our priorities regarding the energy transition, but at the same time we’re reinforcing that oil and gas production is compatible with the energy transition. A digital and data-driven exploration and production strategy will enable us to create positive results here.”

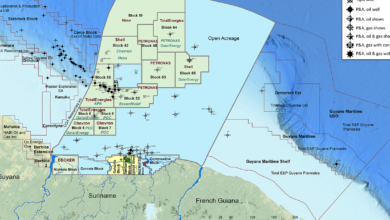

During the 2023 Offshore Technology Conference in Houston on 2 May, Mr Mendes described Petrobras’ vision for a “low-carbon energy ecosystem,” or a business that integrates E&P in frontier areas, such as the Brazilian Equatorial Margin, with low-carbon energy sources such as offshore wind energy and hydrogen production, to reduce its environmental footprint.

Data analytics and computing power are lynchpins to this ecosystem. Over the past couple of years, Petrobras has launched a pair of new high-performance computers (HPCs), Pegasus and Dragon, that are running machine learning algorithms to process geological and geophysical data. Pegasus has a processing capacity of 21 Petraflops, roughly equivalent to the processing power of 150,000 laptop computers, while Dragon provides 14 Petraflops.

Pegasus and Dragon currently rank 35th and 73rd, respectively, on the Top500 project’s list of the most powerful non-distributed computer systems in the world. Petrobras also has two older HPCs, Fenix and Atlas, that came out in 2019 and 2020, with less processing power.

Because processing geophysical data to create seismic images involves complex mathematical equations, having these HPCs has led to a significant reduction in data processing times, Mr Mendes said. He also noted that the four HPCs provide Petrobras with enough processing power to deploy high-usage third-party software programs like EXP100, which uses AI and machine learning to predict the likelihood of hydrocarbons being present in a given reservoir. That reduces the number of exploration wells needed and, in turn, reduces the company’s emissions.

“We have a database with 70 years of operations, a collection of a vast amount of data from different fields and developments. Machine learning is necessary to help us capture and process all of this data that’s available to us, and it’s also important to have sufficient processing capacity. High-performance computing is a stepping stone to achieving greater efficiencies in our operations. We’re foreseeing an increase in the use of predictive models that can help us reduce the number of wells we have to drill,” he said.

Low-carbon energy efforts like CCS make up the other side of the business ecosystem that Petrobras is building for the energy transition. In its 2023-2027 Strategic Plan, the company outlined its ambition to store 80 million tons of CO2 by 2025. In 2022, it stored 10.6 million tons of CO2, which accounted for approximately 25% of the CO2 stored globally that year, according to the Global CCS Institute.

Mr Mendes noted that Petrobras is studying the implementation of a CO2 capture and geological storage hub. The project would involve the construction of pipelines from industrial facilities and E&P projects into a saline aquifer reservoir with a potential storage capacity of 25 million tonnes/yr.

A pilot project is under development near a Petrobras-owned natural gas processing facility in Cabiunas, Brazil, to sequester up to 100,000 tonnes/yr of CO2 over two years. This will serve as a testing ground for the viability of storing CO2 in a saline aquifer and will involve geophysical studies of the drilling of injection wells in the aquifer. Petrobras says it anticipates receiving government approval to proceed with the project later this year.

Because of projects like these, the regulatory environment in Brazil will be critical in helping Petrobras meet its CCS goals, Mr Mendes said. He noted that an expansion into industrial CCS represents a departure from the traditional role of the national oil company; as such, the company’s statute, which is established by the Brazilian government, does not include a regulatory framework or business model for CCS. The bulk of the CO2 that Petrobras stored last year came from the development of pre-salt fields, but the CCS hub includes plans for the company to find industrial partners to provide CO2 for storage. In 2022, Petrobras sponsored a bill that would regulate economic activities related to the permanent storage of carbon dioxide. That bill is still under discussion in the Brazilian Senate.

“Collaboration is essential to a sustainable energy transition,” Mr Mendes said. “By working together, businesses, governments and regulators can scale up the actions that enable the low-carbon energy ecosystem. Latin America is well positioned with regards to these energy projects. It’s a good location to develop energy ecosystems.” DC