Jackup offshore Malaysia deploys automation platform with 3rd-party, closed-loop apps

Phased approach allowed crews to trust the apps as they were taken out of advisory mode

By Stephen Whitfield, Associate Editor

While automated systems have become an increasingly important component of rig-site operations, they typically still require a “human in the loop” to implement parameter changes – for instance, a target ROP or weight on bit.

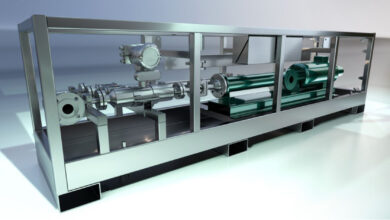

NOV’s drilling automation platform (DAP), which is designed to integrate with the rig control system to automate drilling processes, uses customized apps for repetitive drilling activities without a human in the loop. This can make the automation process less prone to errors. Recently, the company modified the architecture of its DAP to incorporate third-party apps that can automatically update drilling and equipment operating parameters set within the platform, effectively controlling rig equipment on their own.

The DAP previously allowed third-party apps but only in advisory mode, which meant that they could provide suggestions for changing parameters. The platform still needed a human to implement the changes. By allowing third-party apps to control parameters within the platform, the company hopes to provide operators and drilling contractors with the freedom to select and deploy whatever apps they need to optimize automation on the rig.

“We want to show that you can use this automation platform with basically any third party,” said Nahum Ronquillo, Product Line Manager at NOV. “Companies can feel the freedom to open the market to multiple apps. Whether it’s from a big company or a small company, it doesn’t matter as long as they can provide results on the rig.”

At the 2023 SPE/IADC International Drilling Conference in Stavanger, Norway, on 7 March, Mr Ronquillo and Morten Ørevik, Manager of Drilling Automation and NOVOS Engineering at NOV, discussed a 2021 case study where the company integrated two third-party, closed-loop control applications into its DAP; the system was deployed on a Borr Drilling jackup to drill for Petronas offshore Malaysia. The project marked NOV’s first use of multiple third-party applications within its platform.

NOV’s own apps were also installed on the DAP for 12 functions, including things like gel breaking, flow and rotation ramp-up, tagging bottom, drilling a stand, and setting connection height. The system can either execute these tasks by itself or execute commands provided by a human user.

At the beginning of drilling a section with the DAP, the driller assigns control of a given function to the respective app through interfaces that serve as the bridge among the driller, the apps, the DAP and the rig equipment. The driller can set operating limits for a given app to perform a specific function, and the app is allowed to update parameters once it is given control of a task. The driller can then monitor the app’s progress and override it at any time.

The interfaces that drillers can use to assign control of a function to an app are grouped into five categories. One category is drilling disruptions, where the driller assigns an app a task that disrupts the drilling process, typically to mitigate a drilling dysfunction. Another category is dynamic envelope protection, a set of three interfaces that cover the parameters associated with hoist constraints, flow constrains and rotation constraints. The flow/rotation control category covers interfaces that control the current flow and rotation set points while drilling. The drilling parameters control interface handles drilling parameters, such as ROP, weight on bit, torque and differential pressure. The DAP’s process parameter control interface controls the parameters within the DAP’s default drilling processes.

NOV also built in two levels of operational boundaries within the DAP to ensure that the apps cannot negatively impact the safe operation of the rig. One boundary covers tool limits, which are hardcoded into the DAP’s logic controllers; these are designed to ensure that no piece of equipment can be asked to perform at a level that jeopardizes their functionality. Another boundary, well plan limits, ensures that an app cannot automatically modify the operator’s well plan.

Planning and testing

The purpose of the Malaysian operation was proof of concept, to show that third-party apps could control various rig operations on their own. NOV initially tested each app in a cloud-based simulator for compatibility with the DAP. It also ran stress testing and a malicious code inspection to ensure the apps did not compromise the platform’s security or functionality.

Two apps that were developed by third-party service companies were added to the DAP. App 1 covered automation friction tests, circulation, backreaming/reciprocation and tripping/drilling envelopes, and App 2 covered ROP optimization, directional drilling control, flow/RPM downlinking, stick-slip mitigation and stringer mitigation.

NOV, Petronas and Borr used a phased approach to integrate the platform with the rig control system. In Phase 1, the platform was fully deployed while Apps 1 and 2 were deployed in advisory mode. This phase involved training the crews using a simulator that was brought out to the rig, as well as coaching during live operations. Mr Ronquillo said the goal of this phase was to get initial crew adoption of automated operations using the platform, which would serve as a stepping-stone for using additional technology and operating procedures introduced by the apps.

In Phase 2, both third-party apps were taken out of advisory mode. For this phase, integration testing was performed to evaluate the platform and app control handovers and to establish the platform’s operational procedures. Like with Phase 1, this phase included significant on-site training to address human factors associated with the introduction of new operational procedures.

Phase 3 involved an iterative automation management approach to sustain performance. This phase covered software management through continuous software updating, which ensured the system ran with up-to-date patches and the latest features and functionality. It also covered performance management through continuous monitoring and analysis of KPIs and access to NOV support staff. In addition, this phase focused on ensuring continuity and proper coordination with the different stakeholders, escalation of issues as necessary, implementation of lessons learned, feedback to software developers and identification of additional training needs.

NOV tracked multiple KPIs throughout the project’s execution. Operational performance was measured by comparing the automated mode KPIs against manual mode KPIs.

One KPI looked at ROP optimization, which was done by comparing ROP performance while drilling the same-sized hole section in several wells in the same field, first without the DAP and then with it. In the initial use of App 2, NOV observed a decrease in ROP performance.

However, as app usage continued and operational procedures were reinforced, ROP targets were surpassed. In the first well, NOV noted a 12.5% decrease in ROP from manual mode to automated mode. The second well saw a 3.33% decrease in ROP, the third well saw a 30% increase, and the fourth well saw a 26.7% increase.

“That increase in ROP was expected,” Mr Ronquillo said. “The important thing when you see that initial drop in ROP is to stick with it and make sure that the crew continues to be confident in the automation system. Then, you start to get the performance improvements.”

Performance was also tested in terms of using the DAP to trip drill pipes and casing. The rig achieved record run in hole (RIH), pull out of hole and connection speeds using the automated platform – Mr Ronquillo said that App 1, which handled tripping envelopes, enabled Borr Drilling to record the fastest drill pipe tripping speeds among its jackup fleet. The drill pipe tripping RIH speed in the case study was 22.6 stands/hr, higher than the previous record of 18.9 stands/hr.

The Borr Drilling jackup is still drilling with the DAP, although NOV said it is working with the various stakeholders on new apps that would further expand the platform’s automation capabilities. DC

For more information, please see SPE/IADC 212468, “Case Study of the World’s First Offshore Implementation of a Drilling Automation Platform with Multiple Closed-Loop Applications.”