SPM frac pump surpasses 13,000 pumping hours in the Permian

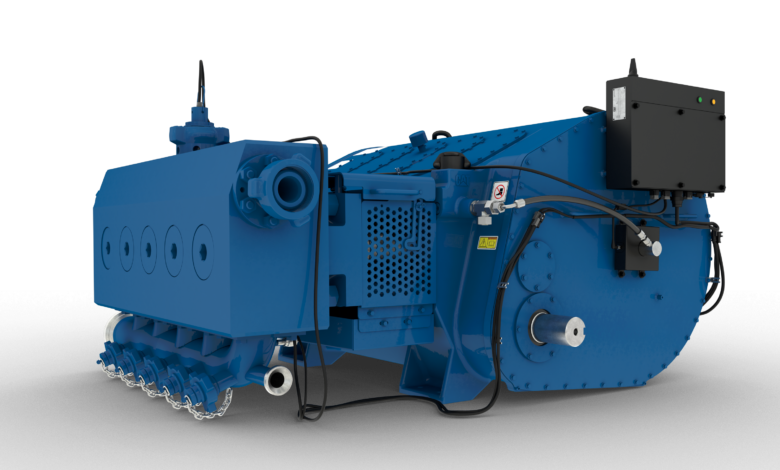

SPM Oil & Gas announced that an its WS 335 Frac Pump achieved more than 13,000 pumping hours in the Permian before its first overhaul. Conventional frac pumps are commonly rebuilt at 3,000 hours and discarded at 6,000 hours.

The WS 335’s single-piece cast frame construction eliminates welds, which reduces failure risk and nonproductive time (NPT) compared to conventional frac pumps. Additionally, the on-board lubrication system maintains consistent oil pressure across critical components.

The WS 335 averaged 15 pumping hours per day at an average of 9,000 psi. The overhaul was performed as a routine maintenance protocol. The frame was found to be free of cracking and the gear train and crankshaft exhibited minimal wear. The main bearings and all soft bearings were replaced before the WS 335 was returned to the field to continue pumping more hours.

“Oilfield service providers operating near continuous duty need pressure pumping equipment that’s capable of withstanding extreme operating conditions to maximize their ROI in the field,” said Derek Kamp, vice president, oil & gas, Caterpillar Inc. “With hundreds of WS 335 frac pumps in operation, many exceeding 12,000 pumping hours, pressure pumpers are equipped to push their fleets harder.”