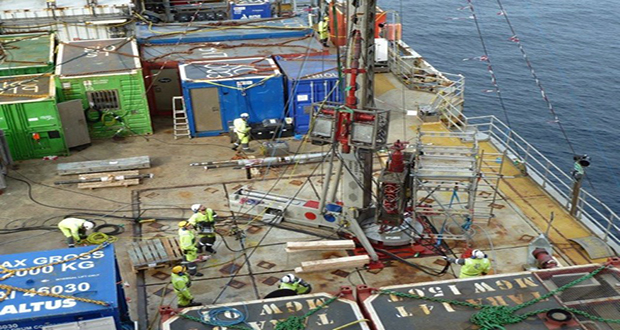

Fiber optic sensing campaign carried out via intervention on Statoil’s Huldra installation

Ziebel, a Stavanger-based provider of specialist well intervention services for the oil and gas industry, has completed a distributed fiber optic (DFO) sensing campaign for Statoil. The Z-Line, a gravity-deployed carbon composite cable, was used to gather distributed temperature and distributed acoustic fiber optic data on the Huldra installation, Statoil’s first unmanned platform, which ceased production in September 2014. The interventions were carried out to optimize Statoil’s plans to plug and abandon the installation next year.

From the Huldra platform, the Z-Line was run in two wellbores to measure temperature and acoustic profiles. Work was carried out over two separate three-day periods in April and May 2015. Each operation was completed as planned, providing data that displays the conditions of each well in its entirety during each intervention. It allows Statoil to observe fluid movements, confirm the integrity of the wells and plan the final abandonment.

It was the first time that Statoil has commissioned a DFO sensing operation via intervention, Ziebel’s first operation for Statoil and the first fully commercial well interventions carried out with the Z-Line.

“As Statoil prepares to plug and abandon the Huldra platform, we appreciate how important it is to have a comprehensive picture of well conditions in order to formulate the optimum approach,” Ziebel CEO Stig Hognestad, said. “Given that it was the first time that Ziebel has worked for Statoil, it was very satisfying that we were able to use the Z-Line to provide them with critical data that will enhance their understanding of those conditions.”

Z-Line builds upon the Z-System carbon composite technology, which delivers critical decision-making well information to oil companies. The key difference between the two is that the Z-Line does so from a smaller wireline footprint, and, being gravity deployed, with a typically shorter intervention time per well.

The Z-Line is a 3/16 -in. (4.8-mm) diameter carbon composite line with embedded optical fibers at its core. This enables distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) to be performed along the full length of the line. In addition, optical point pressure and temperature sensors are contained within the bottomhole assembly (BHA), along with a connection to enable standard memory logging tools to be run below the BHA. The rig-up and footprint are similar to that of a standard wireline cased-hole setup, although the distributed measurement acquisition method does differ in that it is carried out with the line parked stationary in the well.

The carbon composite material enables the line to have an extremely high strength-to-weight ratio, with a breaking strength (6,600 lb/3,000 kg) well in excess of what can be achieved with a similar diameter of steel wire or braided line. The smooth outer finish makes for effective sealing, and the low friction coefficient to steel plus the relative stiffness of the line gives it increased ability to reach into deviated wells. In addition, the low friction reduces the abrasion and tubing wear associated with standard wireline or slickline runs.

DFO sensing makes it possible to continuously monitor the entire wellbore over extended periods of time. Unlike classical logging tools that can survey only a few inches of the well at a time, DFO provides a complete wellbore profile that is captured several times per second. As a result, dynamic events moving along the wellbore can be tracked, which provides a better insight into the wellbore dynamics and added confidence to well integrity decisions. For example, a gas leak migrating upwards can be followed and its speed measured, and intermittent events that would otherwise escape detection by traditional point measurement logging tools can be observed and diagnosed.

Z-Line is a registered term of Ziebel.