Enhanced intelligent well system reduces need for well intervention

By Katie Mazerov, contributing editor

Superior Energy Services (SES) has introduced a new generation of its Hydraulic Actuated Well Completion (HAWC) system, an intelligent well (IW) technology with an on/off feature that allows one zone to be shut off while work continues on another zone. Tool features include retrievable solutions, isolation methods, alternate production means and integrity enhancement specifications. The system can help operators complete, produce and remotely control multiple zones without well intervention. Earlier this year, Anadarko Petroleum Corp awarded contracts to SES to implement the HAWC system for several Gulf of Mexico (GOM) completions.

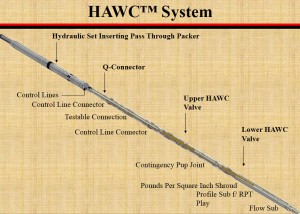

More than 70 deployments of previous-generation intelligence systems led to the development of the new HAWC system, said Dewayne Turner, development manager for Superior’s Completion Tools. Comprised of at least two remotely operated hydraulic sliding sleeves and a retrievable hydraulic set-in-string packer, the enhanced system is deployed as part of the production string and works in conjunction with the SES sand face equipment that is installed adjacent to perforation intervals, Mr Turner explained.

“The packer has been certified to American Petroleum Institute (API) standards at 350°F and 12,500 psi, and incorporates a pressure-assist feature that ensures system integrity during the life cycle of the well.” The packer also can be configured with several release choices, including shear release for shallow water and cut-to-release for deepwater, with internal/external release option. The design also provides the flexibility to pass through multiple control lines through the packer as needed.

The system uses a unique anti-vibration connector that is testable and incorporates a triple ferrule, yielding all-metal-to-metal seals. The internal sleeves are keyed to align the inner flow slots with the external body slots to minimize erosion. A proprietary seal stack on the sleeves minimizes shifting forces, prevents production entrainment and enhances seal longevity due to wellbore pressure differentials during cycling of the sleeves for production.

Intervention Costs Reduced

“Conventional sand control is performed on roughly 30% of the wells completed worldwide,” Mr Turner said. “Of those, very few are done in deepwater. This technology is suited for all selectively produced completions. In deepwater, intervention for such completions are extremely cost-prohibitive and thereby provide a platform for the application of IW technology. Ultimately, our HAWC system eliminates intervention costs and maximizes production potential through optimal reservoir management by the operator,” Mr Turner said.

SES sand face systems incorporate pressure-actuated production initiation technology valves, which eliminate the need to mobilize slick line or coiled tubing. “These sand face systems, when deployed in conjunction with the HAWC system above, form a truly intervention-less IW completion,” Mr Turner explained. “The intervention-less production initiation technology comprises various hydraulically actuated fluid loss control/production devices.”

Designed for both onshore and offshore applications, the system is suitable for GOM wells with wet trees that are typically placed far away from the platform, anywhere from 2,000 ft to several miles, Mr Turner noted. “Production is achieved by hydraulically actuating the zonal production sleeves,” he said. “Production is then managed and selected remotely by operating the HAWC sliding sleeves.”

The technology has allowed one operator to complete some wells while initiating production on other subsea wells, switching to the most productive zones to maximize production and keeping the platform productive for the life of those wells, Mr Turner said.

HAWC is a trademarked term of Superior Energy Services