En route to ‘goal zero,’ Sharpe believes well intervention simulator will help Shell reach higher level of competence

By Joanne Liou, editorial coordinator

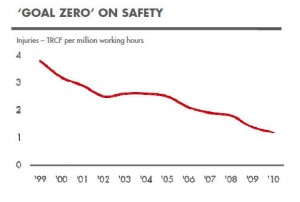

Descending lines on a graph often illustrate a positive trend in the industry’s strive to better its safety performance and to eliminate HSE incidents. The statistics are promising and reflect an improvement year after year, but Shell has its sights on reaching “goal zero,” which represents zero injuries. Although the goal is a tough challenge, Peter Sharpe, executive VP wells at Shell International E&P, believes his organization has the ability to achieve it by having competent people.

“At the moment, about one person gets hurt for every million manhours worked, across every segment of the business – upstream, downstream, construction and drilling. But we’ve had projects that worked 17 to 18 million manhours without a single person getting hurt – a demonstration that it is possible. We can achieve it,” Mr Sharpe said last week during a media conference at the Shell Exploration & Production International Centre in Rijswijk, The Netherlands.

For Shell, the official launch of its new well control training course on 5 December at the Rijswijk facility is one step the company is taking to have the best-trained people to reach their goal. “As a starting point, all of our people are competent,” Mr Sharpe said. “But we’re always looking to raise the bar, and that’s why today is an important day for us.”

Shell currently has about 17,000 active wells, with about 140 active rigs drilling new wells, according to Mr Sharpe. The company spends approximately $10 billion a year on well activity and 1,700 people work in the wells department worldwide. “All of those people have one thing in common,” Mr Sharpe said, “and that is they all started going through a basic training program when they joined. It does differentiate us from the rest of the industry.” Shell engineers spend the first four years of their career learning how to design wells and how to manage well operations safely. Only 80% graduate from the accredited training program.

The company’s commitment to growing competent people to achieve “goal zero” is representative of its approach to safety, which has two parts that involve a balance between personal safety and process safety.

While the industry tracks personal safety performance sufficiently, there’s a lack of metrics for process safety performance. “One of the challenges to process safety is getting our staff to understand it,” Mr Sharpe said. “If you don’t have really good metrics to see how you’re doing, it’s actually quite difficult for leaders to ask the right questions. If you believe organizations are driven by where leadership pays attention, it’s critical to have a system of how you’re doing so you can start asking the right questions.”

Pre-Macondo, Shell had a set of global standards in place, real-time operation centers monitoring rigs, well control equipment certified by the original equipment manufacturers, etc. Shell reviewed what they had in place and analyzed what they had learned and areas where they could do more. “One of the things we talked about was this advanced well control course,” Mr Sharpe said, “which is not just for Shell. We’re not saying we want to have some competitive advantage here; we want to offer this to the industry.”

Course components in well engineering surface, well engineering subsea, completion and well intervention surface, and completion and well intervention subsea make up the advanced well control training course. The well engineering courses were rolled out earlier this year, and the completion and well intervention courses began last week with the new well intervention simulator.

“For me the most important thing is that we have an industry level of competence that is required. If the industry doesn’t, then the regulators should really be pushing for a much higher level of accreditation,” Mr Sharpe said. “I think we’re getting good support from IADC and IWCF in accrediting this training. That’s one of our goals to continue pushing the industry standards to a higher and higher level.”