Drilling & Completion Tech Digest

StayTrue shaped diamond element technology saves bit trip in Hogshooter formation

Baker Hughes recently deployed a seven-bladed Talon Force PDC bit outfitted with the new StayTrue shaped diamond element technology to drill a challenging vertical section in Oklahoma’s SCOOP shale play in Stephens County.

Baker Hughes recently deployed a seven-bladed Talon Force PDC bit outfitted with the new StayTrue shaped diamond element technology to drill a challenging vertical section in Oklahoma’s SCOOP shale play in Stephens County.

The 12 ¼-in. section had to be drilled through the Hogshooter formation to reach the operator’s targeted Woodford shale production zone. However, the Hogshooter formation is characterized by interbedded sections of hard, high-strength sandstones, limestones and dolomite. These can cause premature bit damage and drive up the number of bits needed.

After continuing experiences with erratic footage, inconsistent rates of penetration and poor dull conditions, the Talon Force and StayTrue solution was deployed. In contrast to offset wells that required two or more bits to drill each vertical interval, the new solution drilled through the Hogshooter formation to the target total depth in a single run. In addition to saving a bit trip, the solution also improved footage by 142% compared with offsets, with no drop in average ROP. When pulled out of the hole, the bit showed significant improvement in overall dull condition compared with previous bits, according to Baker Hughes.

Downhole data facilitates liner deployment in long laterals

A string-dynamics logging tool from National Oilwell Varco (NOV) was recently deployed for a field development that included installation of long 4 ½-in. completion liners. To ensure success, the operator would need a strong understanding of the downhole dynamics during deployment of the lower completion liner.

A string-dynamics logging tool from National Oilwell Varco (NOV) was recently deployed for a field development that included installation of long 4 ½-in. completion liners. To ensure success, the operator would need a strong understanding of the downhole dynamics during deployment of the lower completion liner.

The NOV logging tool was installed directly above the liner-hanger running tools to continuously record axial loads, torque, temperature, pressures and other data during each liner run.

The data recorded provided input to confirm torque modeling and friction to improve liner deployment parameters for rotating liners. Accurate and detailed axial-load data near the liner-top tools confirmed successful and unsuccessful setting of liner-top packers. After a packer began leaking early in the project, procedures were updated with revised slack-off loads. All subsequent packer installations were successfully set and tested. In total, 98.9% of the planned completion liner depth was realized on this drilling campaign – more than a 36% increase from previous campaigns.

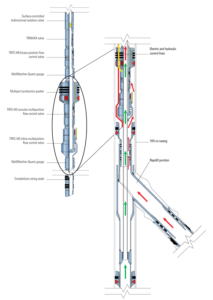

Multilateral technology maximizes production in Caspian Sea

Lukoil recently worked with Schlumberger to optimize well designs on a Caspian Sea field suffering from early gas breakthrough.

The operator’s initial extended-reach horizontal wells completed with inflow control devices (ICDs) experienced production declines within three months of gas breakthrough. To delay the gas breakthrough and maximize oil production, the companies developed an advanced multilateral well design that included a horizontal mainbore with one horizontal lateral. The RapidX TAML 5 high-strength, hydraulic-sealed multilateral junction was recommended because it provides the flexibility to drill sidetracks in any interval of the well and enables hydraulic isolation of each lateral.

The intelligent completion string included WellWatcher Quartz premium high-temperature, high-resolution PT gauges and TRFC-HD flow control valves to help monitor and control each leg of the well separately and, in the event of catastrophic gas breakthrough, maintain production while controlling the gas-oil ratio (GOR).

The strategy resolved Lukoil’s technical challenges, including slot restraint, low recovery factor, high GOR, catastrophic gas breakthroughs and noncontributing toe zones. The well now consistently produces approximately 3,200 bbl/day with water and gas ratios better than nearby wells.

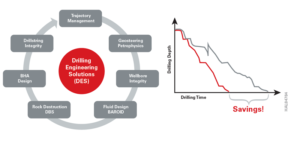

DES helps save $7.2 million in Mexico’s shallow waters

In Mexico, an operator had been drilling shallow-water wells in approximately 93 to 105 days due to sub-optimal ROPs and time required for hole cleaning. To keep its operations economically viable as oil prices declined, the operator partnered with Halliburton’s Drilling Engineering Solutions (DES) team. DES, which integrates multiple service lines, supported the project with multidisciplinary teams.

The DrillingXpert software was deployed to integrate the drilling system in one package, including drilling models and integrated processes from Sperry Drilling, Baroid and Drill Bits and Services (DBS). NAV drilling efficiency solutions also were used to perform detailed well studies. Additionally, the SHIELD risk mitigation solution helped to conduct real-time evaluations of the hydraulic model to optimize drilling parameters and increase ROP, while ensuring well integrity.

Together, the operator and the DES team were able to deliver an optimal well path trajectory, a bit with proven performance in a similar formation, higher hydraulic power to the bit, a better bit-nozzle position and an optimal drill pipe selection for higher flow rates.

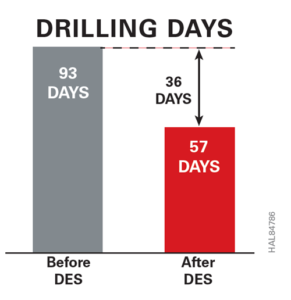

The joint effort between the operator and the DES team succeeded in cutting 36 days from the drilling program, a reduction of approximately one-third of the original number of days. The improvement was achieved by increasing the ROP and by reducing unnecessary circulation, setting a new benchmark for the field.

The operator saved $7.2 million on this operation, while potential annual savings were estimated at $39 million per rig. This means potential savings for all future wells on this development total $117 million.