Drill pipe logging sub uses real-time downhole data to improve liner, lower completion installations

Tool leverages wired drill pipe platform to eliminate guesswork at surface, reduce NPT

By Kim Mathisen, Tore Sorheim, Vijay Kumar Keerthivasan and Dustin Young, NOV Completion; Stephen Pink, NOV Wellbore Technologies

In the well construction process, after pulling standard instrumented bottomhole assemblies (BHA) to surface, the subsequent liner deployment typically happens without any sort of downhole sensors or diagnostics. The liner is often subjected to the most strenuous conditions during well construction, and an unsuccessful installation can add significant amounts of nonproductive time (NPT) and other costs for operators.

Surface data, torque and drag simulations, as well as previous experience, are commonly used to plan and facilitate liner installations. However, field development campaigns often present challenges that cannot be sufficiently planned for by using these resources. Such challenges include reaching target depth during run in hole and critical cement jobs where liner rotation is required for quality zonal isolation.

The availability of live data during liner deployment through a real-time drill pipe logging sub (RT-DLS) tool would take away a lot of guesswork at the surface, minimizing NPT and allowing operators to overcome a steep learning curve for challenging field development campaigns.

Building a real-time platform

To develop a real-time data acquisition platform on which the RT-DLS tool could operate, three conventional data logging technologies were incorporated: the wired drill pipe (WDP) platform, a real-time drilling dynamics tool used in drilling applications, and a memory-based drill pipe logging sub (MB-DLS) used in completions.

WDP is a real-time data acquisition platform that has been used on more than 146 wells, including 65 offshore, since 2015. It provides the infrastructure to support real-time monitoring of operations. It consists of wired tubulars, repeater subs and a data swivel that is installed below the top drive, allowing the drill string to rotate while functioning as the primary connection between the drill string and the surface network.

Since its initial development, WDP tools have been expanded to incorporate along-string measurements featuring RPM, vibration, pressure and temperature measurements. This has opened up visibility to data in locations not normally accessible with downhole tools with real-time data transmission capabilities and in operations where flow was limited, such as liner running or well control.

The MB-DLS tool is equipped with an electronics package consisting of sensors, batteries and memory gauges. The tool is placed in the drill string at one or several points where information concerning string dynamics is desired, most commonly on the top liner hanger running tool. It has no internal or external upsets that can cause activation balls, wiper darts or any other objects to hang up.

The MB-DLS has been used since 2013 for several field developments during the running and installation of liners and lower completions. This includes field developments for major operators globally and for most major operators in the North Sea. The top of liner data collected by the MB-DLS has proven to be valuable by facilitating a fast learning curve, optimizing completion installations and utilizing the full capabilities of the liner string.

The RT-DLS tool couples this WDP platform with the data acquisition of memory-based dynamic logging tools to provide operators with real-time access to axial loads, torque, temperature, pressures, vibrations and RPM during lower completion and liner deployment operations. It ensures immediate access to critical data for completions as they are run, while also capturing this data for use in future completions.

Real-time data logging sub development

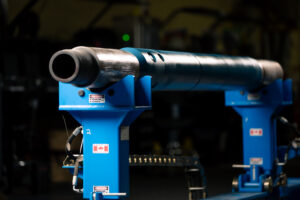

The three key mechanical components of the RT-DLS tool are the main body, the wired connection sleeve and the electronics housing. That housing contains the batteries, main and ancillary boards, and a memory board. The memory board allows users to utilize the tool as a memory-based logging tool in applications where WDP is not available.

The annular pressure sensor, internal pressure sensor, temperature sensor and strain gauges are located on the main body. Various sensors enable measurement of pressure (internal and external), loads (tension and compression), torque, vibration, RPM and temperature.

The key challenge in developing the RT-DLS tool was to ensure that it was robust enough to meet the load, pressure and torque parameters, while also allowing for a sufficiently large inner diameter that would allow for passage of liner balls and darts. An 8-in. outer diameter allows the tool to be run inside 9 ⅝-in. casing to install 7×9 ⅝-in. liner hanger systems without limiting the operation with regard to tool dimensions and mechanical capability.

The design of the mechanical body was optimized to withstand the load limits using finite element analysis. In the engineering calculation process, critical sections of the tool exposed during various loading scenarios were first identified. Finite element analysis was also performed on these sections to ensure that the maximum stresses in the tool were below the yield strength of the tool during various loading scenarios. Further simulations were carried out to characterize the pressure drop across the tool during a dynamic flowing scenario. These simulations showed that, at higher flow rates, small changes in fluid densities will result in more pronounced changes in the pressure drop.

Upon completion of the engineering analysis of the design, prototypes of the tool were manufactured for full-scale lab testing. The successful validation of the tool was completed in April 2020.

Real-time data logging sub applications

Having access to real-time data during liner or other completion deployments through the RT-DLS tool can provide significant value in field developments. In the initial wells during a campaign, live downhole data can be used to visualize challenges during each run and tell users how the decisions they make at the surface impact downhole tool behavior. The data and learning gathered from these initial wells will enable a steep learning curve that could benefit the later wells of a drilling campaign.

Users will typically utilize the RT-DLS tool on field developments that have a WDP system set up on the rig. However, the tools will also be available on an as-needed basis when companies are running liners and other lower completion systems. This will facilitate the identification of operational issues and help users take remedial actions during these installations, as opposed to learning after the job from memory data.

De-risking liner running operations

For instance, a typical challenge for operators is cementing the liners and lower completions with rotation on the drill string for optimal cement placement. Lower completion equipment can include rotations as part of the installation; several liner hanger system designs feature a running tool release mechanism that includes string rotation. The RT-DLS tool provides an actual number of string revolutions downhole. This and axial load are key parameters to understand, establish and confirm best practice procedures in these sequences.

The live data provided from RT-DLS tool can serve as an early warning if cool fluids pumped influence the position of the liner running tools, which can potentially put the cementing operation at risk.

Pressure is often used to manipulate and operate downhole tools used on liners in various ways. Operators are often reliant on surface pressure readings and the manipulation of rig pump rates to achieve the desired pressure to operate these tools, but other pressure variations occur downhole without the means of monitoring at surface. Closed-end displacement and piston effects from pipe movement, as well as varying fluids with differing specific gravities, result in pressure variations at depth and can negatively influence liner installations. Real-time data downhole is useful as a checkpoint and, in many situations, can be the main pressure reading used in liner installations.

Accurate and detailed load data near the liner top tools provide confirmation of successful (or unsuccessful) activation of liner top packers. Activating a liner top packer results in a distinct and repeatable load and pressure signature. Understanding the shape of these signatures is very useful when packer failures occur, as it’s possible to confirm if the packer has been activated properly. Live top-of-liner data will dictate and confirm the packer setting and total set-down weight on top of the packer. Real-time monitoring sub data can be used actively in the planning and execution of future wells with regards to surface set-down weight, with operators verifying the impact of adjustments made from previous wells.

Live top-of-liner data with axial loads and torque can also be vital information for projects where deployment limitations and challenges are identified and experienced during run in hole. The load data recorded will provide accurate, real-world input to drag modeling software for tuning friction factors and optimizing model output on the fly. Feeding surface and top-of-liner data into a torque and drag model will result in a more accurate model, and companies can use the data to anticipate potential friction-related issues before they happen in order to take appropriate actions.

The future of real-time downhole data acquisition

The RT-DLS tool is the first step in opening the liner and completion space to real-time in situ downhole data acquisition. Looking to the future, access to the WDP network will enable the industry as a whole to develop innovative solutions and enhancements to current processes.

With the acquisition of high-fidelity data during the installation of the lower completion system, it is possible, for instance, to reduce the uncertainty of setting weight or pressure, as these measurements can be obtained in situ. The ability to monitor downhole real-time pressure and weight can improve the industry’s understanding of running procedures to reduce swab/surge and maximize the success of these operations by taking decisions at the time, not after the fact, and decrease the number of operationally induced wellbore issues.

As part of future developments of the real-time data platform for completion operations, the development of smart interfaces could enable ball/dart-free activation of liner hangers, with instant feedback on activation and confirmation of setting. The instrumentation of service tool assemblies could open the door to a net reduction in associated failures and issues, thereby reducing the likelihood of expensive remedial actions, particularly in high-cost deepwater operations.

Moreover, as the industry moves toward autonomous operations and moving personnel out of harm’s way at the rig site, acquisition of data from the rig site at the right resolution will allow users to incorporate certain critical operations into process control algorithms and protocols.

The acquisition of continuous downhole weight, torque and pressure could enable automated liner running with a level of precision and reduction of risk not currently available. However, it requires adoption, engineering and a return on investment.

The evolution of data acquisition and other diagnostics tools using the WDP platform is ongoing. Further opportunity exists to develop new measurement tools, technology and interfaces that will enable direct connectivity with completions and monitor downhole operations, such as gravel packing and the running of service tools. DC

This article is adapted from SPE/IADC 204127, “Improve Installations of Liners and Lower Completions with Real-Time Downhole Data,” presented at the 2021 SPE/IADC International Drilling Conference, 8-12 March 2021.