Better understanding of data, physics key to BHA optimization

Companies realizing that a more holistic approach may be needed to enable precise directional control while optimizing ROP

By Stephen Forrester, Contributor

In an industry that continues to face financial headwinds, it is more important than ever that drilling is a cost-effective endeavor. Solutions over the past decade have achieved some success in the cost per foot of drilling, but those solutions have often focused on optimizing individual items within a given bottomhole assembly (BHA) – for example, implementing a more powerful motor or a more precise rotary steerable system (RSS).

Although such pieces of equipment and technology, when incorporated individually into a BHA, can improve some performance metrics, the current market environment demands more holistic BHA optimization to achieve better results. By looking at BHAs with a more critical eye, companies can work to improve operational efficiencies, reduce equipment damage and associated maintenance costs, and decrease the capital necessary to drill wells.

Understanding drilling dynamics

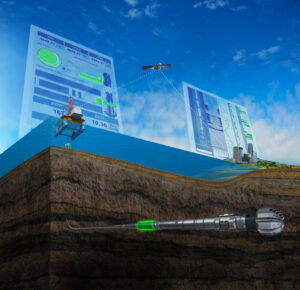

For NOV, BHA optimization involves a modern systems approach, where both service companies and operators need to examine designs and configurations more critically. Tony Pink, Chief Technology Officer of NOV’s Wellbore Technologies segment, believes that he’s seeing an ongoing transition in BHA design. “We’re seeing high-tech BHAs with a drive system, likely an RSS, connected via MWD/LWD and real-time, along-string drilling dynamics tools, into wired drill pipe,” he said. “Real-time data is acquired by the rig at surface and analyzed, and answers are determined by the system using that data set. This enables full closed-loop automation back to the drilling control system, which communicates with the RSS and sends a setting to geosteer the well and deliver accurate, precise reservoir placement.”

In line with the industry’s shift toward remote operations, NOV aims to design BHAs that optimally function while removing people from the rig site and placing them in a real-time operating center.

The company also believes that advancements in drilling motors, which will be powered by digital software that automatically talks to the rig’s control system for orientation and steering, will fundamentally change directional drilling. The company is developing software with embedded artificial intelligence and machine learning, which allows the software to continually learn and optimize drilling parameters, as opposed to basing decisions on a simple lookup table.

The challenge is that, while enabling precise directional control, ROP also needs to be optimized.

Mr Pink laments that the industry has lost its understanding of the fundamentals of drilling dynamics, like stabilizer placement and design, the appropriate amount of inertia in a drillstring to overcome the shear modulus of the formation, and so forth. Much of the loss has stemmed from the great crew change, as well as repeated downturns and volatile business cycles.

“This is leading,” he said, “to some bad practices, with people developing cut-and-paste BHAs not based on physics and engineering, not based on the actual interaction of all the conditions downhole. Poor BHA design then leads to poor drilling performance, which necessitates costly BHA redesign. So, you drill an extended lateral with a large bent housing on the motor in a slide/rotate pattern and end up unable to reach TD due to excessive drag at the end of the well. The operator solves the problem by implementing an RSS, but they could have just reduced the bend on the motor and slid/rotated the well more proficiently to reduce tortuosity and achieve the appropriate borehole condition.”

He believes that companies relying on these types of technological band-aids are driving costs up against conservative AFEs when they don’t need to be.

One of NOV’s answers to this challenge is the SelectShift downhole adjustable motor, first field trialed in 2018 and now commercial in more than 200,000 ft of hole. Steve Pink, Western Hemisphere Director of Technical Sales for Drilling Optimization and Automation, explains the tool: “Once you land the well horizontally, you can put the motor in a more benign bend setting, therefore allowing higher surface RPM, better hole condition and cleaning, reduced spiraling/tortuosity, and higher ROP. It’s a mechanical motor without costly, complicated electronics, which reduces failure points in the system.”

In a 2019 project in the Permian Basin, the SelectShift motor was used to drill an entire vertical/tangent section to the kickoff point (KOP) while effectively holding inclination and improving bit life. Due to a challenging mix of sandstone, siltstone and limestone, the previous bit was pulled before reaching KOP and damaged beyond repair. After configuring the motor to operate between 1.83° and 0° bend settings, the operator reached the KOP without having to trip, drilling 2,719 ft with the motor in the 0° setting. Hole inclination was easier to hold with the tool in straight mode, reducing the number of slides by 57% versus the offset well, and the bit dull grade of 1-3-BT-S-X-I-CT-KOP was significantly better than that of the previous bit.

Mr Tony Pink said he believes that the next frontier of BHA optimization will be in geothermal applications. “If we’re going to drill and expose significant amounts of hot rock, we need tools that can survive in extreme temperatures; we need BHAs that can handle high-energy, hard rock environments; we need cutting structures that can achieve high enough ROP to make the wells economic; and we need new cooling systems and high-temperature electronics.”

NOV recently created a geothermal group focused on improving its existing technology to be viable in geothermal applications. By transferring the oil and gas industry’s technology momentum into this new domain, commercial geothermal drilling at scale is not as far away as some might think, he said.

Drilling performance analysis

For Schlumberger, BHA optimization focuses on the understanding of downhole events and drilling performance limiters that cause operators to trip unnecessarily. The company has developed a portfolio of technologies that enable quick analysis of post-run data and subsequent adjustment of drilling parameters to optimize drilling performance and efficiency.

Additionally, the tools aim to reduce premature tool failure and maintenance through the evaluation of performance and tool placement within specific BHA designs.

The company has two key services for optimizing BHA design and performance. The first, the Synapse performance insights and optimization service, uses an in-bit memory-mode shock and vibration logging device to analyze tool performance and evaluate optimal placement within a given BHA design. Gerard Johnson, Product Champion for Schlumberger’s Well Construction Drilling portfolio, explains that the service allows “operators to create an intelligent network of sensors and feedback throughout the BHA, monitoring the downhole environment to enable continual BHA optimization – both in the sense of drilling efficiency and overall equipment reliability – in different applications.”

The service performs post-run data analysis using automated, cloud-based data workflows to allow operators to quickly identify performance limiters and generate recommendations for BHA improvements on future wells. “Downhole, surface and formation evaluation data,” Mr Johnson said, “are uploaded to this cloud, where algorithms merge and synchronize the inputs into a report, which can then be used to generate a drilling performance roadmap for optimized BHA tool placement.”

This data can also be instantaneously visualized and reviewed by Schlumberger. In addition, operator personnel can zoom in on areas of interest within each report, allowing them to take a micro-level view of BHA performance and drilling parameters that enables scalable improvements based on well design and expected downhole phenomena.

In a 2020 project, an operator sought to reduce the number of trips in highly interbedded formations in the Marcellus Shale. Using the Synapse service to better understand downhole conditions and drilling dysfunctions that could affect BHA performance, Schlumberger generated drilling parameter roadmaps for the operator that allowed them to complete the section using only one bit instead of two, which is typically required for similar drilling scenarios in the region.

“Not only did this save the operator the expense of running, and potentially damaging, two bits,” notes Mr Johnson, “but it also reduced their drilling time by 12 hours, yielding savings of approximately $50,000.”

Another key tool in Schlumberger’s BHA optimization toolbox is the OptiDrill real-time drilling intelligence service, which monitors surface and downhole data and enables event detection and customized reporting. Rigsite displays integrate the downhole and surface data to provide actionable information, allowing the operator to mitigate risk and increase downhole drilling efficiency.

The real-time data is interpreted by remote Schlumberger experts, who collaborate with drilling engineers onsite to improve performance. The surface data is integrated with borehole calipers and images from LWD logs to evaluate wellbore stability throughout the drilling process; combined with the detection of spiraling for bending moment data, this information helps operators drill a smoother wellbore for running casing.

A suite of downhole drilling mechanics and dynamics subs allows the service to identify the type and severity of BHA motions, calculating continuous borehole friction and factors that cause drillstring failures, equipment damage and issues like stuck pipe. The service is intended to be used for both short-term parameter optimization to improve ROP, as well as long-term analysis of trends, performance limiters, risk on future wells and process improvements.

An operator in the Gulf of Mexico undertaking a salt drilling campaign in 2018 was looking to optimize common rig activity, enhance drilling operations and improve benchmark performance while ensuring adherence to strict HSE guidelines during well construction. “By using the OptiDrill service,” Mr Johnson explained, “the operator actively managed shock and vibration through real-time drilling parameter optimization recommendations, which led to average on-bottom ROP improving from 73 ft/hr to 141 ft/hr.”

Schlumberger is also working to develop new technologies that can be run with wired drill pipe for ultrahigh-speed data transmission. Advancements into BHAs that can function within new energy applications, such as geothermal, are also part of the company’s ongoing research and development efforts.

Design optimization app

Corva believes that software should not only help select better pieces of downhole equipment to comprise the BHA itself but also allow optimization of drilling parameters and performance via the knowledge gained from apps. The company’s BHA Optimization App, which can be accessed via a web-based platform, provides customizable monitoring and analytics tools built on understanding live data from the field and determining optimal parameters with it.

Senior Customer Success Manager Darhan Sydykov notes that at the core of the BHA optimization app is this question: “What, exactly, is a good BHA?” With BHA design varying dramatically based on factors such as downhole conditions, wellbore geometry, well location, available resources, and geology and lithology, there is no one clear answer.

In the past, drilling engineers might review BHA performance data – often delivered in individual reports – from a drilling campaign, aggregate the data, analyze it and make a recommendation on any changes moving forward.

This repetitive, time-consuming process saw technical experts becoming what Mr Sydykov calls “data wranglers,” with many spending around 80% of their time looking through the data and only 20% using that data to make more effective decisions.

Corva argues that this percentage should be the other way around, with the data being presented in a clear and easy-to-understand way up front to provide drilling teams with more time to analyze it and develop an appropriate plan. Users can filter data to make more relevant comparisons.

The process begins with ensuring that the app is fed with good data. “First,” Mr Sydykov noted, “wellbore schematic and directional plan are uploaded to Corva’s cloud-based system, automatically generating a template of the well from this static information. Then, we tie into live rig data via a WITSML stream so that users receive a real-time view of what’s going on with their BHA. Real-time rig-state detection, accomplished via a proprietary algorithm, allows for detailed visualization, so that users always know BHA conditions and drilling parameters. BHA and mud reports from the field are also input to allow real-time torque and drag modeling, hydraulics modeling, and other more advanced functionalities.”

The BHA optimization app features a set of user-defined charts and a list of BHAs, with a color-coded schematic that provides insight into the BHA’s overall design. In each drilling performance category for a given BHA, a green or red designation on a parameter means that the parameter was either optimal or out of spec, respectively, allowing Corva to work with customers on a per-BHA basis to continually optimize its design as part of an iterative process. Small insights into the impact of individual drilling parameters can provide a significant benefit to drilling crews looking to better understand how a BHA holistically functions within a given downhole environment.

In one study of the time to drill five production vertical sections, Corva’s app identified one underperforming well, according to Drilling Optimization Engineer Chris Schneider. Comparing BHA performance between that well and its offsets, then analyzing individual BHA designs and drilling parameters, allowed the customer to clearly understand the problem.

Despite comparable wellbore geometry, a dissimilar BHA design had been used to drill the well with slower ROP. Looking at the performance of the other four wells, the customer determined the optimal benchmark well to use as a template for BHA design in the subject well.

“We helped the customer identify potential operational savings of 1.42 days by changing BHA design to correspond with the best offset well using similar drilling parameters,” Mr Schneider concluded. DC