INPEX acquires Block 2A offshore Sarawak, Malaysia

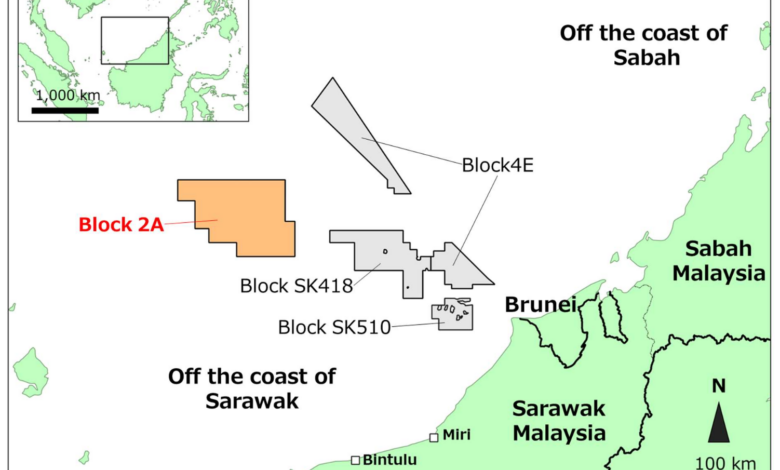

INPEX executed an agreement with Seascape to acquire 100% of the shares in Longboat Energy (2A) Limited, a subsidiary of Seascape that will own a 42.5% participating interest in the Block 2A Production Sharing Contract. Block 2A is located offshore Sarawak, eastern Malaysia in the North Luconia hydrocarbon province covering approximately 12,000 sq km in water depths between 100–1,400 m. Block 2A contains the world-class Kertang prospect, located across four Oligo-Miocene reservoirs.

Block 2A was originally awarded to Seascape in February 2023 as part of the Malaysian Bid Round 2022 by PETRONAS Malaysia Petroleum Management. MPM acts on behalf of PETRONAS in the overall management of Malaysia’s petroleum resources throughout the lifecycle of upstream oil and gas assets.

INPEX will assume operatorship of the block where it will engage in hydrocarbon exploration activities alongside partners Topaz, a wholly owned subsidiary of Seascape, PETRONAS and Petroleum Sarawak Exploration & Production.