Autonomous drilling at scale: How close are we?

A fully automated rig has been piloted in the Permian, but economic and interoperability challenges will likely keep near-term focus on automating specific tasks that can realize tangible efficiency gains

By Stephen Whitfield, Associate Editor

In recent years, the industry has mostly reached consensus around the value of automating critical functions in drilling operations: It has great potential to improve safety while driving efficiencies and performance improvements, both on the rig and in the wellbore. Results have been well documented. However, when it comes to the viability of deploying fully automated drilling rigs at scale, there doesn’t seem to be much of a consensus yet.

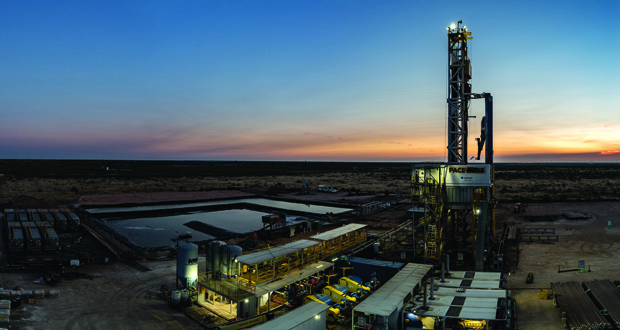

Some believe full automation at scale is not that far off from becoming a reality. Perhaps the prime example is Nabors Industries’ PACE-R801, a fully automated land rig which completed a pilot campaign for ExxonMobil in the Permian Basin this year.

“When we can move people out of harm’s way, that’s a good thing,” said Brett Schellenberg, Director of Controls and Automation at Nabors. “Automation enables us to do that. Just as importantly, it allows us to standardize the best practices from our best drillers, derrick hands and floor hands and standardize those things and repeat them consistently across our fleet to improve our cycle times.”

Another perspective in the industry is more skeptical that the industry will see fully automated rigs dominate the landscape in the near future. Commonly cited obstacles include the development of standard control interfaces that can be used from rig to rig, as well as the financial challenges of building new rigs or performing capital-intensive retrofits with systems that can fully automate the wide range of tasks still being manually performed by humans.

In this article, DC speaks with two drilling contractors, an operator and a service company to explore their current views on autonomous drilling and discuss recent efforts to advance automation.

Achieving a fully automated rig

Nabors has been at the leading edge of fully automated drilling with the R801 rig, which was in development for five years before it was deployed last fall. It combines the company’s automated drilling software with robotics to remove personnel from red-zone areas and deliver consistent results. During the pilot project with ExxonMobil, the rig drilled nine wells across three pads. In total, it has drilled, tripped and cased approximately 2 million ft.

To enable full automation on the rig, the catwalk was replaced with a robotic pipe handler. This robotic arm handles drill pipe and tubulars up to 13.375-in. diameter and contains its own spinners for connections and tripping. Drillers control the robot from the driller’s cabin using an automated tubular management application that was incorporated into Nabors’ SmartROS, a software application that controlled the rig’s control system and managed the equipment on the rig.

By inputting the specifications of different tubulars being used on the rig floor into the tubular management application – for instance, the inner and outer diameters of a drill collar – the movement of the tubulars were tracked automatically, with the app’s algorithms automating the process. The app also measures the torque of each connection and relays that information to the robotic pipe handler.

Developing this intelligent tubular management system was one of the biggest challenges in fully automating the rig, according to Ram Murthi, Senior Manager of Control and Automation at Nabors. This was primarily because the system had to account for a wide variety of tubulars, as well as ensure precision and accuracy in the tubular’s positioning. On top of that, it also had to be able to manage the flow of the tubulars from one system to another and coordinate with other processes and equipment on the drill floor. Another key aspect of the rig’s full automation was Nabors’ Smart Suite of automated drilling software that runs on its SmartROS rig operating system. R801 incorporated several of Nabors’ existing software solutions, and new ones were also specifically developed for the project.

One example is SmartDRILL, an automated drilling activity sequencer that configures drilling workflows to follow best practices. Engineered sequences were programmed into the app so it can automatically deliver the bit to and from bottom, during a connection and around a slide. It also was intelligent enough to automatically update the sequences when needed to avoid unexpected downhole hazards. Another app featured on R801 is SmartSLIDE, a directional control steering system that automates slide drilling.

While the rig floor of R801 was crewless, Nabors said it still maintained roughly the same level of staff at the rig site – they just had different duties. There was still always a driller onsite to supervise the overall operations, while other crew members performed essential tasks associated with maintenance, inspections and rig moves.

A few design changes were also made on the rig to ensure the safety of crew members. The red-zone area was fenced and equipped with motion-detection sensors connected to the drilling control system. If the sensors detect a person has entered the area, the moving equipment in the red zone stops automatically. The driller’s cabin was also elevated above the rig floor, slightly higher compared with a standard land rig. This was primarily meant to help drillers better observe the automated rig floor and further remove them from potential hazards.

While no detailed performance data from the pilot project was provided, Mr Schellenberg noted that the campaign saw zero OSHA recordable incidents and that well times approached the average of Nabors’ best West Texas fleet.

Having proved fully automated land drilling is possible, Nabors is now focused on retrofitting the software and robotic components of the R801 onto its other existing rigs – without the need for major redesign. Later this year, the company plans to deploy modularized automated systems on an existing Nabors rig. This move, Mr Schellenberg said, better suits the current economic realities of the industry.

“As we start to commercialize these products, we really want to be able to focus on modularization, being nimble and flexible to whatever the rig configuration may be,” he said. “As you start to see future iterations of rig floor automation, our focus will be scalability on existing rigs. Capital is not as easy to come by anymore, so we need to be thoughtful about providing these technologies without putting customers in a position where they need to build an entirely new rig.”

Targeting automation at tangible benefits

Many people in the drilling industry remain skeptical about the viability of achieving fully autonomous drilling in the near future, especially at scale. Mark Anderson, VP of Drilling Solutions at Ensign, pointed to the complexity and variety of tasks completed by humans on the rig. They are far too great for an autonomous system to fully handle, particularly at a reasonable cost for drilling contractors, he said.

“To have an autonomous rig, you have to have every single task and all the contingencies automated, and the economics of that is not going to be feasible in terms of development costs,” Mr Anderson said. “Also, we have a huge installed capital base of equipment. I don’t think we’re going to go out and scrap 2,000 modern AC rigs for an autonomous system.”

Instead, Mr Anderson said he sees automation as a “journey.” Rather than trying to develop fully autonomous rigs to deploy at scale, it’s more likely that drilling contractors will expand the list of tasks on the rig that can be automated. At Ensign, in addition to developing its EDGE Rig operational system – which combines an automated control system with cloud-based machine learning algorithms to optimize drilling performance – it has recently focused on developing tools for automated reaming, MSE-based ROP optimization and automated downlinking to the rotary steerable system. It is also developing a prototype to automate toolface control.

Further, Ensign developed a human/machine interface with drill-down capability for all rig equipment, as well as a one-button connection system where the driller can start an automated sequence of certain critical functions on the rig with the push of a button. The system activates the top drive and the pumps, driving the bit to bottom.

“The driller makes the connection, picks up out of the slips, hits one button and goes about doing other stuff, like managing the crew, all while the system lowers the bit on bottom,” he said. “It picks up off bottom, reams if needs to, turns off the top drive, stops the mud pumps and then allows the driller to deactivate the system. Drillers love that system. We’re trying to improve little parts of the drilling system, and then the humans can do the other parts we haven’t gotten to yet.”

Mr Anderson said he also believes remote operations of automated systems will generate a significant economic benefit for drilling contractors in the coming years. “The equipment control system doesn’t really care if the controls are coming from a human or a PLC. It will raise or lower the drawworks regardless. If you require more weight on bit, it doesn’t matter if that command comes from the unmanned drilling control system or a human. You can change set points from an offsite center, where you go in and change variables in your automated drilling control system remotely. Those are areas where we can get a real benefit.”

Can full automation at scale become reality?

While Occidental (Oxy) has engaged in automation on a limited scale for years, it has no plans for a fully automated rig in the near future, according to John Willis, VP of Drilling and Completions for US onshore. Currently, the operator’s automation efforts focus on the deployment of 11 automation applications from drilling contractors and third parties. Outside of these applications and any other automation tools offered by its drilling contractors, the operator sees “full automation,” including pipe handling, more as a long-term goal.

Mr Willis pointed to pipe handling as a key obstacle in automation at scale. It remains one of the more complex tasks humans perform on the rig, given the variety of pipe sizes and predefined positions within a pipe-racking system. While some work has been done to develop automated pipe handling for land rigs, he said cost is a sticking point.

“The problem with a lot of these automated systems is that none of them has ever been competitive with good rig crews. Good crews have always been faster and cheaper,” Mr Willis said. However, he does see changes from 10 or 20 years ago, with systems such as robotic arms that can be retrofitted onto existing rigs. “It’s very different today. To me, it’s just a matter of time before the robotics get good enough that it becomes feasible.”

Another hurdle to full automation at scale is the lack of interoperable systems that can be used from rig to rig. Gaps in critical functions that Mr Willis said still need to be filled include a standard control system interface and a standard system for automation apps to work simultaneously. Further, he pointed to a need for a standard interface to transfer well plans into a rig’s automated control system. Having interoperability between well planning data and rig systems, as well as the ability to configure automation parameters remotely, will be critical to realizing full automation at scale.

He added that current automation systems still require significant amounts of manual data entry and system configuration. Rather than helping drillers – especially the less experienced ones – they often demand more from the drillers. This makes those systems difficult to implement, especially in today’s environment when it’s become more difficult to hire experienced rig crews.

“The vision for automation is that it will allow consistent performance despite inexperienced drillers,” Mr Willis said. “Today, however, the use of automation requires so much data entry and system configuration that, instead of allowing for less-experienced drillers, the drillers need to be experts on manual processes and experts on configuring the automation system.”

He also pointed to the fact that drilling is a cyclical industry. “Rig counts go up and down. When it goes down, we lose people, and when activity picks up, we’ve got to go hire people. And every time we hire new people, they make mistakes as they learn. Two ways to reduce the learning curve are to capture knowledge in automated systems and retain it in remote experts. Then that expertise from your great people, stored in automated systems, can be applied consistently, well after well. The knowledge of experts supervising rigs remotely can be applied on many rigs instead of one.”

Integrating MPD into rig controls

Managed pressure drilling (MPD) has become a widely accepted method for drilling wells in formations with narrow pressure windows. However, the process of implementing MPD services on the rig can be time-consuming and expensive, particularly for deepwater projects. For some drilling contractors, integrating MPD systems into their rig’s automation infrastructure, including hardware, software and procedures, is a way to streamline the process.

NOV has been working to ensure its MPD systems work seamlessly within a rig’s automation system, according to Mark Mitchell, Senior VP of Managed Pressure Drilling. When the rig’s control system is updated with MPD capability, drillers can access additional controls, MPD screen views and data trends. The MPD system does not take the place of or obstruct the driller’s access to conventional drilling tools. Rather, it enhances the visibility of downhole conditions and provides the driller with additional tools to drill the well as safely and efficiently as possible.

“A big part of drilling the well is taking specific data sets, MPD data being one of the subsets, and aggregating it to display useful information that allows for faster and more accurate decision making, ” Mr Mitchell said. “The level of automation is important; if everyone only automates and integrates their own data subset independent of one another, then the full potential of the system is not realized.”

System controls can be connected directly inside the rig’s control system or integrated indirectly through NOV’s NControl software platform. This open architecture platform communicates with the rig’s control system and any third-party interfaces important to MPD operations, such as mud logging. The level of integration is based on the rig owner and operator’s preference.

In 2018, NOV incorporated the active control device (ACD) into its product portfolio. The ACD is an active, non-rotating sealing device for MPD operations that seals the wellbore annulus and diverts returns using a sealing sleeve energized by an annular packer system. As the seal sleeve wears, the system automatically varies hydraulic closing pressure on the seal to compensate for wear and accommodate the passage of wear-inducing tool joints.

The ACD is an active system instead of a passive system, like a conventional rotating device. The design eliminates the need for complex bearing assemblies and high-wear rotary seal components, which cause nonproductive time during MPD operations.

Additionally, it allows the control system to monitor the seal element condition, enabling the driller to proactively plan for seal replacement. When in operation, the driller can manually adjust the seal closing pressure or allow the ACD to run in auto mode. The control system automatically makes these adjustments based on sensor feedback.

“With an RCD, you never really know the condition of the seal until it’s not sealing anymore, whereas, with the ACD, we can understand when it’s time to change the seals. Also, as the seals wear during operation, we can apply additional closing pressure, effectively regenerating that sealing surface,” he said.

There are currently eight drillships using the ACD for MPD operations worldwide. Over 30 wells have been drilled with this technology since it became available. DC