Maersk relies on new ways of working to drive energy efficiency without large capital investments

Project focused on embedding energy efficiency into existing processes, procedures without adding complexity for rig crews

By Lola Caballero, Rune Loftager, Konstantin Puskarskij and Johan Karlsson, Maersk Drilling

As part of the larger energy landscape, the oil and gas industry is confronted by an impending energy transition. Like many other industries, oil and gas is facing increasing demands – from customers, shareholders, investors, authorities, employees and other stakeholders – to become more sustainable. The answer to this must be to transform the business to continue delivering affordable and reliable energy but in the most sustainable way.

Maersk Drilling fully recognizes its responsibility in relation to the energy transition and, in 2020, announced one of the most ambitious targets in the offshore drilling industry by committing to reduce greenhouse gas (GHG) emissions intensity from its operations by 50% by 2030, compared with a 2019 baseline. To realize the targeted savings, Maersk Drilling has defined two key levers: increase the energy efficiency of its drilling operations and unlock new low-emission energy sources, such as external power or alternative fuels.

Timing to combat climate change is important, and the implementation roadmap was divided into two phases. While the second lever – low-carbon energy sources – is not yet mature and available at scale and would require large capital investments, the first phase is being implemented in a new way of operating Maersk Drilling assets, with a heightened focus on reducing GHG emissions by increasing the efficiency of drilling operations. This is based on available technologies and can be initiated immediately.

Initial findings show that great results can be achieved without large capital investments. Rather, the results are driven by management commitment, collaboration, engineering acumen and dedication throughout the organization to embrace changes.

Energy Efficiency Embedded Project

The greenest energy is the energy we don’t use and, for this reason, energy efficiency will play a key role in the decarbonization roadmap of any organization due to cost efficiency and high potential. Saving energy by changing the way a drilling unit is operated and maintained, or by implementing relatively inexpensive technical upgrades, has the potential to significantly lower GHG emissions from drilling operations at relatively low costs.

However, to fully leverage the energy efficiency potential, several enablers must be in place:

A paramount condition for a successful decarbonization rollout is management commitment. Full alignment with the organization’s priorities and strategies is crucial.

A clearly defined target and the roadmap for getting there must be designed, including concrete milestones.

A dedicated decarbonization team with responsibilities and mandate to drive the emission reduction agenda across the organization.

The ability to create awareness by using data analytics – for example, using onboard IoT sensors to relay real-life data for processing, modeling and visualization.

The ability to provide data insights and context regarding the energy consumption of equipment, systems and drilling operational modes, supporting identification of hidden efficiency potential.

Strong collaboration between onshore and offshore, as well as with customers and the entire value chain, to ensure lockstep around emissions-reducing initiatives.

With the above enablers in place, emission-reducing initiatives can be coordinated and deeply embedded into the way drilling operations are conducted in the most efficient way. This was done by Maersk Drilling under the Energy Efficiency Embedded (EEE) project, which rests on three pillars:

Ability to measure the GHG emissions levels from the operating rig(s), directly or indirectly (reverse calculation).

A willingness by the organization to set ambitious emission reduction targets and build awareness around emission reduction opportunities through advanced analytics and continuous feedback to rig crews.

Leveraging the available data and analytics and embedding energy efficiency into the management system by adjusting relevant processes and procedures that govern the way the company operates its fleet.

The three pillars proved to be equally important in supporting the project within the organization and in securing sustainable development after the project was turned into operational processes and workflows.

Efficiency Embedded Playbook

The EEE project follows the Plan-Do-Check-Act (PDSA) continual improvement framework, also outlined in ISO 5001, where:

Plan: understand the context of the organization, formalize the EEE project charter, assign the resources and assemble the EEE project team, consider actions to address risks and opportunities, review historical emission levels and energy consumptions numbers, identify significant emitters and establish energy efficiency baselines, and establish energy budgets for individual assets.

Do: execute the project as per the project plan, implement updates to the Maersk Drilling management system, assign offshore Energy Champions, establish operational and maintenance controls, roll out an awareness campaign focused on the EEE project and energy efficiency in general, and consider energy efficiency through technical upgrades and offshore crew competencies.

Check: monitor energy efficiency developments, measure emission levels, analyze each individual asset’s equipment and systems energy efficiency performance with a focus on potential improvements, benchmark performance among sister vessels, conduct offshore energy audits, and arrange management reviews and awards.

Act: establish a lessons learned database, address non-conformities and continually improve energy efficiency.

Preparing for impact

During the planning phase, it was agreed to introduce energy budgets for individual drilling rigs and place accountability for the budgets with the rig teams. The budget targets for the individual units were set using the baselines calculated for the respective units. The baselines for the individual unit’s energy consumption and emission levels were defined using:

- Historical average daily consumption for drilling activities, taken from Business Intelligence reports;

- Rig type (drillship, semi, jackup);

- Operational status (operating, in transit, stacked, etc);

- Station-keeping considerations (moored,

DP, DP assisted, self-elevated); - Environmental aspects (harsh environment, high current, benign conditions, etc);

- PMS configuration for self-propelled rigs (open or closed bus);

- Third-party package onboard;

- Ambient temperature; and

- Any specific client or regulatory requirements.

- The energy budget targets were defined as an emission reduction in percent against the original baseline and can be monitored in the Business Intelligence report.

The Energy Budget tab is a part of a comprehensive solution called Energy Efficiency Insight. This Business Intelligence report allows monitoring of energy and fuel consumption of the individual drilling rig but also provides an operational context to these consumption numbers by cross-referencing them with various parameters of the drilling rig. Hence, the solution does not only provide consumption and emission data but also insights for the crew to understand why the consumption is at a given level, and to make an initial analysis of where potential optimizations can be made.

The project team identified risks and opportunities, which were mostly related to the embedment of the energy efficiency initiatives into daily operational activities and anchoring these initiatives with rig teams. Based on previous experiences, it was agreed to seek support from the dedicated Business Performance function within Maersk Drilling. A dedicated resource was assigned to the EEE project.

Decarbonization is a team sport, hence a basis for the project planning was that the plans had to be aligned and/or co-created with representatives from the rig crew. “Offshore Ambassadors” were nominated for every drilling rig. During the planning phase, the project team, together with Offshore Ambassadors and other stakeholders, performed a gap analysis between “as-is” state and “to be” state. The “to be” state was defined by combining the strategic EEE project goals and what the offshore teams identified as realistic and sensible actions. During the gap analysis, triggers for behavioral changes needed to get to the “to be” state were identified and added to the project scope as deliverables.

Delivering impact

Saving energy and reducing emissions through behavioral changes requires an open mindset. This can be as simple as switching off the lights in a room or switching off one thruster or idle equipment, such as drawworks or rig pumps. This can be done by establishing communication channels to facilitate the right conversations.

The campaign’s approach and rollout plan was established in the project planning phase and implemented in the execution phase. This was done with a focus on supporting global rig crews in changing their collective behaviors and practices in order to conduct daily operations in the most energy-efficient manner, consequently lowering emissions and meeting energy budgets.

Another stream focused on ensuring that energy-efficient behavior was supported by the management system. A number of procedures, processes and solutions were amended to include energy efficiency aspects and sustainable changes:

- An energy efficiency awareness slide added to safety induction video;

- Agenda of HSE meetings was expanded to include energy efficiency;

- Agenda of daily planning meetings was expanded to include energy efficiency;

- Shift handover documents now include energy efficiency checkpoints;

- DP manual was updated to include guidance on energy efficiency;

- Maersk Drilling’s offshore portal now includes a dedicated space for sharing energy efficiency content;

- Energy efficiency was added to review scope by the HSE department;

- Agenda of customer performance update meetings was expanded to include an energy efficiency topic;

- Client rig appraisal questionnaire was expanded to include energy efficiency metric; and

- Management recognition reporting.

No new processes were created to accommodate energy efficiency. Instead, it was embedded into well-established workflows. Furthermore, during project execution, knowledge transfer documents were distributed across the fleet to encourage technical upgrades through available rig budgets or upselling to the clients.

Evaluating the impact

During the planning phase, the following means of measuring energy efficiency and evaluating the effectiveness of actions were built into the design:

- Review of individual rig energy efficiency performance vs energy budgets;

- Benchmarking between rigs of the same type;

- Analyzing the individual asset’s equipment and systems energy efficiency performance with a focus on potential improvements;

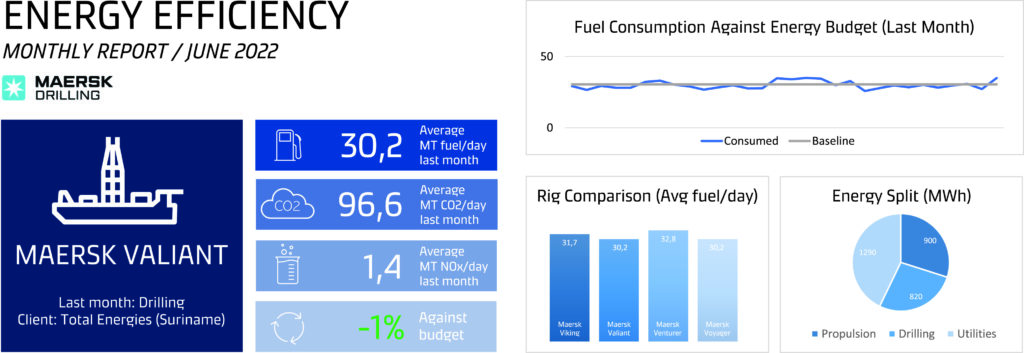

- Publication of monthly rig emission reports (Figure 1);

- Conducting offshore energy audits;

- Arranging a management review of the results; and

- Ensuring that the best-performing rigs are recognized and rewarded.

- Success criteria for behavioral changes were also outlined to measure the project:

- Concrete activities that were taken as a result of the project;

- Positive effects observed in relation to the realized project deliverables; and

- Detected energy efficiency improvements in relation to the realized project deliverables.

An example of the Business Intelligence energy budget screen.

The list of concrete activities that were carried out included offshore conversations (Figure 2), feedback from the rigs with concrete actions proposed to improve energy efficiency, meetings with clients, workshops with offshore representatives, and weekly check-ins with Offshore Ambassadors.

During the planning phase, 10 project deliverables were defined, all aimed at triggering energy-efficient behavior and increasing emission reductions from ongoing operations. In the evaluation phase, eight out of 10 deliverables met the success criteria. The remaining two were moved to the improvement phase.

Furthermore, post-project energy efficiency from the equipment and systems that were addressed during the project was compared with pre-project efficiency levels. A generally positive trend was documented.

Project objectives and targets were evaluated by management, and project success was recognized via documented energy performance improvements, detected by advanced analytics tools. Feedback from management review, where further opportunities for improving energy efficiency were identified, was moved to the improvement phase.

Project tangible deliverables

Several tangible improvements from the Maersk Drilling fleet can be highlighted to provide context on what can be achieved.

Energy-efficient behavior

Analysis between rigs with the same design and operational parameters allowed the project team to identify optimum parameters and best practices.

The first example is the HVAC system, which contributes significantly to any drilling operation’s overall energy consumption picture. In particular, optimization can be achieved by aligning accommodation temperature and exchange & supply fan speed in different machinery compartments. Savings from HVAC optimization are significant and easy to implement if the optimum parameters are known.

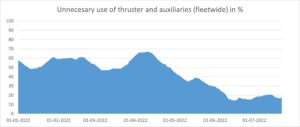

Another example is eliminating the inefficient use of thrusters to support the rig’s station-keeping operations. Again, benchmarking was done with sister vessels. Combined with comprehensive DP simulations, this gave confidence to the marine crew in minimizing the number of thrusters required to perform safe, compliant and efficient operations. Initially this initiative met with skepticism from the marine teams, but collaboration between the teams led to the results seen in the advanced analytics, where the average amount of thrusters online decreased on several units.

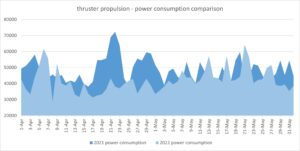

Figure 3 shows a power consumption reduction comparison on a drillship, where it was possible to compare the performance in similar metocean conditions and during similar operations. Figure 4 highlights the impact made on the analytic models when calculating the unnecessary use of thrusters and associated auxiliary systems during the first half of 2022.

Light emitting diode (LED)

Maersk Drilling rigs are on the path to phasing out conventional fluorescent lighting tubes with LED tubes. This not only allows a reduction of approximately 60% of the energy currently consumed by rigs’ lighting fixtures but also increases each tube’s lifetime. One example is a generation 7 drillship where expected fuel consumption driven by the LED initiative is calculated to 220 mT/year. On several rigs, this initiative was co-funded by Maersk Drilling and the client.

CJC Filters

Another initiative is to replace conventional lube oil separators for the main engines with CJC filters. Such an upgrade has been performed on several Maersk Drilling drillships. On some of the vessels, the initiative was co-funded by the client. The savings are significant and measured not just by the fuel saved but also by lubrication oil consumption reduction, as well as a significant reduction in sludge wastes generated by the rig.

Collaboration with clients

As mentioned earlier, some of the energy efficiency initiatives were co-funded by Maersk Drilling’s clients, and Maersk Drilling has generally observed a highly increased momentum in collaboration on sustainability and energy efficiency matters. Together with clients, emission reduction targets for individual wells are defined, various initiatives are implemented during campaigns, and successes are recognized by issuing End of Well Emissions Reports.

Improvement phase

Like any other organization, Maersk Drilling will continually improve the suitability, adequacy and effectiveness of the GHG emission reduction efforts. This is supported by the demonstration of continuous energy efficiency improvement.

The prerequisite to continuous improvement is establishing and maintaining a lessons learned database focused on energy efficiency matters, as well as broader emission reduction considerations. It is important that the lessons learned database is used to plan energy efficiency measures onboard the rigs and that all stakeholders have access to the database and are encouraged to provide relevant input to the database on a continuous basis.

While a significant number of lessons were learned during the EEE project, the most critical were facilitated by anchoring EEE objectives with individual rig teams. This process did not go smoothly across the entire fleet, as some rig teams were able to engage significantly more than others. Analysis of the underlying reasons was conducted and will be used for the next PDSA cycle.

Conclusions

Solely relying on technical or IT solutions will not move the needle and generate the impact needed to address emissions reduction as part of the industry’s contribution to the energy transition. It is all about creating an open mindset and fruitful collaboration, both onshore and offshore. The ultimate goal for the EEE project was, by using the PDSA framework, to create a sustainable and permanent awareness offshore on energy efficiency matters and a willingness to go the extra mile to unlock savings without frequent interventions from headquarters.

And while energy efficiency matters were embedded into the Maersk Drilling management system to play a role in daily operations, they did not increase the complexity for rig crews but rather leveraged existing processes and procedures. In other words, instead of adding more processes and procedures, existing processes and procedures were amended to take energy efficiency into account. This adjustment of structures, processes and behaviors was done through an engaged and trustful collaboration, with a high focus on individual accountability.

The EEE project was determined to be a success and has been extended to the entire fleet. The project and the results were presented to several of Maersk Drilling’s clients, where the overall feedback was positive, recognizing second-to-none big data solutions and how dedicated crews had changed their behaviors to fully embrace the sustainability agenda. DC

This article is based on a presentation at the 2022 IADC Advanced Rig Technology Conference, 30-31 August, Austin, Texas.