Data analytics, artificial intelligence facilitate development of failure prediction models for subsea BOPs

Machine learning and text mining techniques used to turn both structured/unstructured data into valuable insights for optimizing maintenance windows

By Alberto Albuquerque, Samuel Lima and Gustavo Carvalho, Delfos IM; Fabbio Leite, Rodrigo Machado and Cristiano Xavier, Ocyan

This article presents how a drilling contractor, Ocyan, worked with a startup company, DELFOS IM, to optimize the maintenance window of subsea blowout preventers (BOPs) through the use of condition-based maintenance (CBM). It showcases examples of insights about operational conditions of the BOP components that were obtained by applying machine learning techniques to real-time and historic, structured and unstructured data.

Digital Transformation

The development of machine learning-based solutions to enable the predictive maintenance of BOPs is only sustained within a broader context of digital transformation. Simply speaking, digital transformation is the implementation of technology to enhance performance and produce better results and reliability for operations and processes. The goal is to create value and knowledge by leveraging the huge amounts of data that are generated on a daily basis.

Modern drilling rigs generate terabytes of non-structured data every day, but only 5-10% of it is analyzed. It is often heard that data is the new oil, but the right resources are needed to refine it and extract the desired value.

Rather than Big Data, one should be looking for Good Data. Data must be managed as one of the most precious assets of a modern, digitally transformed company.

Ocyan SMART Project and Dimensions

This development is part of the Ocyan SMART project. It is an advanced integrated real-time monitoring system where a technology platform is used to collect, synchronize and process data from different sources and communication protocols on the rig and then bring it onshore, thereby integrating people, systems, sensors and processes.

Together with its partners, including DELFOS IM, Ocyan developed dashboards and custom graphs to display the real-time data and generate valuable insights for operations. The most exciting and challenging part of the project has been having data scientists from Ocyan and its partners working together to develop machine learning algorithms, then apply big data analytics to detect and prevent abnormal situations. Then, automated alerts can be sent that enable the engineering support team and specialists to directly intervene. This provides essential information to support the decision-making process. The aim is to apply CBM on critical equipment, using monitored data to improve reliability and to intervene on equipment at the correct time – not too early, not too late.

To give complete and reliable decision-making support for operators and the management team and to have a full picture of what is happening offshore, Ocyan SMART is based on six dimensions: drilling/MPD, well control and integrity, subsea (BOP), power management system, dynamic positioning and CCTV (rig cameras). The development presented in this article is related to the subsea (BOP) dimension.

BOP and Development

The subsea BOP is one of the most critical pieces of equipment on a deepwater drilling rig. A failure in one of its components can cause huge downtime (NPT) or, even worse, an environmental disaster. BOP failures are responsible for approximately 40% of the overall downtime on drilling rigs.

Ocyan recognized that its BOP operational data was not being used to its full potential to plan maintenance interventions during operational windows. The maintenance plan was often overestimated, aiming to cover as much as possible of the BOP stack parts (valves and regulators), which is not suitable in the context of ever-decreasing maintenance operational windows. This led to unnecessary maintenance and costs, as well as wasted time.

It’s becoming more common for industries to apply solutions that can extract the maximum amount of information from the data generated during the operation and maintenance of critical assets. Typically, the goal is to improve activity and maintenance planning, thus increasing equipment availability, reducing downtime and personal security risks, and increasing the general profitability of the assets. In the case of BOPs on Ocyan’s drilling rigs, the challenge was to utilize unstructured historical data to evaluate, in a macro way, the condition of annular preventers and the gap between activations of the HPU pump. Ultimately, the goal was to replace time-based maintenance activities with condition-based ones.

To achieve this, text-mining techniques were applied to identify operational records in the event logger associated with these two components. Then, machine learning techniques were used to develop normal behavior models. This allowed the development of a monitoring system for those component-specific conditions, making it possible to identify deviations from normal before they became a significant operational risk.

It was also recognized that historical knowledge has primarily been based on the experience of individuals, and the quality of any maintenance operation was significantly dependent on the person who was performing the planning or maintenance. For these reasons, Ocyan looked for a partnership with DELFOS IM, a Brazilian startup focused on artificial intelligence for the energy industry, to develop failure prediction models for subsea BOPs using data analytics and AI, enabling predictive maintenance for the BOP’s critical components.

The predictive maintenance strategy is based on the hypothesis that it’s possible to optimize maintenance activities by evaluating the operational conditions of the equipment from available data. Even for an experienced technician, a visual inspection may not be enough to determine, for example, if the elastomer of an annular BOP is losing its properties and is at risk of not supporting the amount of functional and pressurized cycles expected for the next campaign. Similarly, without a historical analysis of the HPU pump activation intervals, it’s not easy to determine if normal system leaks are increasing to the point of reaching an unsafe condition.

From unstructured and structured historical data, which are generated daily from BOP operations, a knowledge bank was built and used to develop normal functioning models. This has been possible even without real-time data, as it has been tested with large sets of operational data collected from event log text files. The analytical models, which are based on historical operational data, then allow the projection of expected behaviors and its comparison with real data, making it possible to identify behavior deviations in advance. This helps to guide the teams responsible for maintenance activities. Teams can now go in-depth with specific maintenance and inspection activities in the components where deviations have been identified, leading to optimized maintenance of the BOP when it’s on the surface and reducing the risk of downtime.

It should be emphasized that real-time structured data is not required to develop normal behavior models for BOP components; it can be done with only non-structured data of the log archives. By establishing a routine of log archives extraction, it’s possible to build specific reports that provide the insights necessary for maintenance events.

Dashboards, Visualizations and Reports

After special treatment of the unstructured event log, data is organized as time series, events and commands for the BOP equipment. Then, analytic models and machine learning algorithms are applied to turn the previously unused data into valuable information, such as:

- Cycle counting for ram and annular BOPs and solenoid valves;

- Annular BOPs’ elastomers failure prediction;

- Comparison of deviations in the volume of fluid used for function activations;

- Leakage or degradation on the HPU pump; and

- Alarm events analytics.

All the information and analyses are presented on an interactive web-based dashboard, allowing users to easily navigate through the displayed information. Additionally, automated reports are generated to help key support users identify the critical issues and facilitate maintenance planning.

The module for monitoring a BOP’s annular condition, at the time of this article, was divided into two sub-modules: cycle counting and categorization of pressurized/non-pressurized cycles; and evaluation of the historical behavior of volume needed to execute the opening and closure of the annulars.

The first has the main role of allowing annular maintenance based on its utilization history. Counting annular BOP cycles not only reduces uncertainty but also makes it possible to account for attributes associated with those cycles, such as time, volume and the flowmeter curve in each activation; active POD; regulating pressure during the function execution; and wellbore pressure during the closed period. It should also be noted that the implementation of the same technique for other preventers, such as pipe rams and shear rams, is made readily extensible and constitutes an extra bit of information that can be utilized for maintenance planning.

These attributes are then used to model normal behavior in the activation of annular BOP functions, the second sub-module. For the implementation of this technique, it is necessary to select a period that represents a healthy behavior of the component. After that, there was an initial attempt to apply multi-varied statistics to identify the expected volume for each function execution, modeled by its attributes. In sequence, after training takes place, it is possible to evaluate the tendency for functional degradation, in which each activation event is classified as normal or abnormal.

The result is a robust method to evaluate whether the behavior of the last cycle indicates normal operation, a possible tendency of elastomer degradation, or even an abrupt increase of fluid consumption, indicating the presence of a possible leak. This allows for operational planning based on the equipment’s condition. Additionally, after switching each elastomer, statistic testing is conducted to evaluate whether the maintenance that took place had any impact on the volume used for the opening and closure of the BOP. This generates an extra insight for maintenance planning.

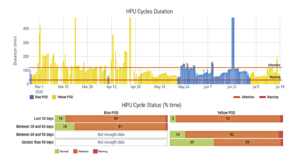

The HPU’s condition-monitoring module was developed to enable advanced identification of leaks in the control system, thus allowing operations based on condition. Currently, the most widely used method for identifying leaks is calculation of the HPU pump activation interval. A high frequency of pump entries is associated with a higher level of leakage. The solution developed aims to continually track the activation interval, classifying each pump cycle by its active POD and the presence or absence of BOP functions execution.

By observing the behavior of this target variable over a long period, it can be evaluated whether there’s a tendency for leakage increase, and it is possible to estimate the time until operational limits are reached. It is also possible to observe sudden behavior variations, which represent a strong indication of leakage in the control system. With this result, the operator can plan its operation so as to not surpass the established limits until the next maintenance window.

Applying the text-mining solution to the event log generates a lateral benefit, which is the possibility of incident history investigations. If the specific BOP data doesn’t have a history, the structure of analog variables, commands executed and alarms raised, along with other forms of information, can enrich the incident investigation process.

Results and Roadmap

During the implementation period, Ocyan was able to identify a BOP failure using the detection algorithms and used 100% of the information generated by the system and reports to efficiently plan for equipment maintenance. The system has also been intensively used for incident investigation, helping to identify root causes through data analytics and retro-feeding the machine learning algorithms for future automated failure predictions.

The roadmap of the partnership between Ocyan and DELFOS in the development of the global condition-monitoring approach includes, besides the availability of these same analyses in real time, the following functionalities:

- Cycle counting and normal behavior model of all the solenoid valves;

- Analysis of the operational health of regulator valves;

- Analysis of alarms and work orders to allow the categorization of failures and improve the calculation of reliability indicators; and

- Condition-monitoring module applied for all BOPs.

The BOP maintenance process, like many other critical equipment on offshore rigs, has room for additional development and can highly benefit by transferring knowledge from other industries. In this context, the applications and roadmap presented in this article represent a great potential to improve the planning of maintenance activities and, therefore, increase its availability, reduce downtime and operational security risks, and increase the general yield of its active components. DC

This article is based on a presentation at the 2020 IADC Advanced Rig Technology Conference, 1-2 September.