2016 IADC/SPE Drilling Conference Abstracts

Tuesday, 1 March

Case Studies – Fixing Problems

IADC/SPE 178878

Multi-Zone Intelligent Completions for Interference Test Data Gathering Onshore Kenya. J.S. Ure, Tullow Oil; A.D. Wenk, Tullow Oil.; T.E. Asbey, Tullow Oil; M. Jha, Tullow Oil; P.A. Peytchev, Tullow Oil

Objectives/Scope: This paper presents the completion design selected and the operational challenges which have been overcome by Tullow Oil in appraising its discoveries in the Turkana region in remote north-west Kenya. These fields are characterised by multiple pay zones spread over relatively long intervals of 800 – 1,000 m. Well TDs are typically around 2,300 m MDRT and the productive zones to date have been sub-hydrostatic in initial pressure. The reservoir fluid is a waxy crude oil (35 – 40% wax content) with low GOR. Flow assurance is a key aspect of the completion design, as the reservoir temperature of the shallower zones is close to the wax appearance temperature (WAT). Methods, Procedures, Process: Until late 2013 the testing of discovery and appraisal wells was rig based, with zones flowed in a ‘bottom-up’ sequence. Using this approach, a five zone well test would typically take 50 – 60 days. The initial focus of well design activity was to increase efficiency of the testing operation however Tullow decided to accelerate its area development planning based on the significant exploration/appraisal drilling success in the basin. Subsequently, completion design efforts became driven to meet a subsurface requirement for the acquisition of transient interference test data from Extended Well Testing involving five wells in two of the discovered fields. The approach which has been successfully implemented has been to make all well testing rigless after the installation of a multi-zone intelligent completion. The completion is complex and consists of a Halliburton digital hydraulics controlled Interval Control Valve (ICV) and downhole pressure/temperature gauge at each completed zone. Zonal isolation is achieved using stacked feedthrough packers above each zone. Downhole heating is incorporated via electric cables for flow assurance and performance evaluation of these is achieved in the two EWT production wells with fibre optic cable distributive temperature sensing. Artificial lift is provided by low speed, long stroke hydraulic rod pumps. The completion was originally designed to be installed inside 9.625-in. casing but the opportunity to realize significant well construction cost savings and to minimize environmental impact has also been taken by successfully trialling a slimmer well design using 7-in. production casing in the three observation wells. Results, Observations, Conclusions: This approach, where the rig is moved off after installing the completion, has resulted in rig time savings of approximately 30 days per well, in addition to providing the flexibility to acquire zone specific transient well test data. Novel/Additive Information: The bigger prize is applicability of the approach to field appraisal data gathering in any discovered field enabling the acceleration of development planning and reduction of the time to first oil production. Additionally, adoption of the slimmer well design will result in significant development well CAPEX saving.

IADC/SPE 178780

Solid Expandable Solution to Qualify Existing Non-Sour Service Production Casing. J.D. Contreras, ConocoPhillips; F. Gamarra, ConocoPhillips; J.L. Becnel, ConocoPhillips; G.G. Galloway, Weatherford

Objectives/Scope: In the early development of the EagleFord Field in South Texas, the initial well design equipped wells with non-sour service P-110 production strings. After the early stages of production, some of these early wells were found to produce increasing levels of H2S, which posed the problem of sulfide stress cracking at shallow wellbore depths because of relatively high H2S partial pressures and associated low formation temperatures. To mitigate this risk, production packers were run to protect the production casing in wells with H2S partial pressures more than 0.05 psi. As these wells were depleted to lower flowing pressures, production was maintained by intermittently producing. This method was used because of limited or no artificial lift options for wells with non-sour service production casing. A solution allowing artificial lift was needed to better maintain and sustain production, to extend the utility of these wells, and to allow future recovery of the potential reserves. Methods, Procedures, Process: Expandable casing technology was ultimately chosen as a solution to maintain well integrity and enable implementation of artificial lift (gas lift). This operation involved the running of an expandable liner to cover and protect the section of the casing susceptible to sulfide stress cracking. A solid expandable tubular designed to support the corrosive environment was successfully tested and qualified for sour service in extreme corrosive conditions by ConocoPhillips metallurgists, who adhered to sour service qualification A.2.1.6 and Annex B of NACE MR0175/ISO 15156 standards. Additional testing was performed to ensure that the required length of the chosen liner could be run while being held at surface. Normally, these liners are left free at the top so that they can slightly shrink in length to avoid high tensile forces as they are expanded outward. The liner also passed these tests performed independently by the service company. Results, Observations, Conclusions: The team proceeded to install the solid expandable liner, from 7,047 ft (where the temperature was high enough that H2S effects were minimal) to surface to protect the existing 5 1/2-in. P-110 casing. The ID of the completion changed from 4.776 in. (original id) to 4.140 in. (expanded liner ID). The well was then completed with 2 3/8-in.-tubing, a production packer, and traditional side-pocket-mandrel gas lift. Currently, the well is producing on continuous gas lift with the casing protected by the expandable liner. Novel/Additive Information: It is important to mention that this is the longest solid expandable liner installed in the world (March 2015). The expandable liner provided an enabling solution that allowed implementation of the optimal artificial-lift method to recover additional resources within the drainage area.

IADC/SPE 178786

First Successful Implementation of an Advanced Fibrous Organic Based LCM and Optimized Casing Design in Europa: A Case Study From Drilling a 6022m HPHT Exploration Well in Vienna Basin, Austria. K. Abdelaal, R. KNEZEVIC, K. Ovrevik, OMV Austria; R. Husodo, Drilchem

Objectives/Scope: This paper lists technical challenges encountered recently during drilling the HPHT exploration well X to 6022m and describes how these new fibrous organic LCM have proven their value in all sorts of lost circulation applications in the Vienna basin. This case represents the first application of specialized organic fiber LCM in Europa. The author will also elaborate on the narrow mud window available and the main drivers for well design along with contingency concepts. Methods, Procedures, Process: The operator identified a special lost circulation product made of organic fiber which has the characteristics that it is plastic, deformable and can be squeezed into the loss zone. This produces a seal over the loss zone with an internal filter cake rather than forming a high fluid loss filter cake on the wellbore itself. Several pills with this specialized lost circulation products were used achieving excellent results when applied in a very specific manner (described in the paper). Detailed decision-tree charts, characteristics and wettability of fibers, function of the patented material and treatment will be highlighted in the paper. Results, Observations, Conclusions: XYZ field in Austria has a history of mud losses ranging from continuous seepage to severe losses. Several attempts were made to explore the referred to structure without success. The main uncertainties in predrilling the well were the magnitude of the overpressure from Alpine tectonics and the severe losses in Olistolithe (part of Jurassic formation) which was the root cause of failure in previous attempts since its thickness was unknown. The operator was able to control the pressure ramp at 3371 m in the 12 ¼-in. hole. Drilling was resumed but was forced to stop again at 3821 m when severe losses beyond 50 cu m/hr were encountered which prevented the operation’s ability to drill ahead. Several attempts to cure the losses with different lost circulation products were not successful. The choice faced was either to run the casing earlier than planned or attempt a new solution to control the severe losses. By deploying this technology, the Operator was able to continue drilling ahead to 4496 m where the 9 5/8-in. casing was run and cemented. Severe losses were encountered in the 8 ½-in. hole and the operator was able to cure them successfully by applying the techniques developed in 12 ¼-in. hole. Novel/Additive Information: Successful implementation of this advanced technique allowed the operator to drill the well using a three string casing design with a final hole size of 8 ½ in. without reducing the mud weight. The level of success achieved by using these materials means it should seriously be considered as the preferred standard practice for curing any type and volume of losses.

IADC/SPE 178813

Real Time Reservoir Mapping While Drilling Reduces Risks, Geological and Fluid Position Uncertainty in the Gulf of Mexico. S. Leveque, Schlumberger; D. Walz, C. Wolfarth, J. McCarty, ANKOR Energy; L. Castaneda Zigala, M. Alexander, C.L. Fulton, H.O. Kadir, Schlumberger

Objectives/Scope: Reservoirs in the Northern Gulf of Mexico (NGOM) are predominantly drilled with low angle wells. Drilling a well horizontally presents its own set of challenges. Mississippi Canyon block 22/21, operated by ANKOR Energy embodies the significant drilling challenges sometimes found in the NGOM reservoirs. The “H Sand” reservoir is a low resistivity (3 to 5 ohm.m) reservoir bounded by a northeast/southwest fault. The overburden is uniform for more than 200 ft true vertical depth (TVD) above the reservoir, making the landing challenging with conventional well placement techniques. ANKOR Energy was planning a 2,300-ft lateral section to be drilled close to the gas-oil contact (GOC). Early water production was observed in the offset well located at the toe of the planned well, raising questions about the current position of the oil-water contact (OWC). Landing this well was challenging from both a geological and drilling point of view as a 3D trajectory was required to avoid the fault and offset wells. Methods, Procedures, Process: In light of these challenges, ANKOR Energy decided to use the newly commercialized deep directional resistivity (DDR) tool with a detection range of more than 100 ft, enabling the detection of the top of the “H Sand” reservoir long before landing. In the lateral section, the tool was used in conjunction with an integrated petrophysical platform to map the top of the reservoir, detect the OWC, and identify the lithology and fluids present while drilling. Results, Observations, Conclusions: While landing the well, the top of the “H Sand” reservoir was detected 48 ft TVD away, 10 ft deeper than expected. The DDR tool enabled the well to be confidently landed despite the lack of correlation markers and depth uncertainty of the “H Sand” reservoir. The OWC was detected more than 70 ft below during the landing section even though the bit had not penetrated the “H Sand” reservoir yet. The top of the reservoir and the OWC were mapped throughout the length of the lateral section along with the lithology and fluid content. Towards the toe of the lateral section, near a producing offset well, the OWC, still 50 ft below the current trajectory, was observed to be rising up and getting closer to the well. TD was called early to avoid premature water production. Water coning was confirmed as the reason behind early water production in the offset well. Novel/Additive Information: The use of this technology during the landing and the lateral section of the well significantly reduced the risk associated with geological uncertainty as well as the fluid contact position providing critical information for field management planning.

Innovating Drilling Into Extreme Environments

IADC/SPE 178857

A challenging HPHT Operation Supported by Dynamic Real Time Simulation, Forecasting and 3D Visualization. J. Nabadi, R. Rommetveit, eDrilling Solutions; J. Wessel, Maersk Training Centre A/S; L. Scott, Wintershall

Objectives/Scope: Dynamic Real Time Simulation, Forecasting and 3D Visualization was utilized extensively in support of a very challenging HPHT drilling operation in the Norwegian Sea. The well was a vertical exploration well in the Haltenbanken area. Methods, Procedures, Process: In preparation to the operation, an advanced training session was performed using a dynamic downhole training simulator linked to a topside rig simulator, for training of the drilling teams. A real-time link was established with the operation, and WITSML data in addition to all well, fluid and string data was streamed into a dynamic, real-time simulation system. This simulation system provided the following: RT dynamic modelling of the pressure (ECD) and temperature profile in the wellbore; the cuttings distribution and its effects on the ECD; automatic look-ahead simulations of ECD and temperatures on the fly was performed with the calibrated models as support for decisions; RT profiles of simulated versus measured pressure at the PWD, and simulated versus measured standpipe pressure; RT dynamically updated 3D Visualization of the downhole wellbore with a continuously updated risk picture made available for the drilling teams. Seamlessly linked to the RT system was a sophisticated what-if and planning model. 24-hour forecasting of operation was provided every day, and this gave a very good indication of future possible operational impacts. In addition to 24-hour forecasting, pre-planning simulations of upcoming sub-operations as well as what-if simulations on the fly were performed. The results from these simulations were used to update the risk register and made available in the 3D Visualization window. Results, Observations, Conclusions: Three specific cases will be discussed in the paper: pre-simulation of running the 13 3/8-in. casing; pre-simulation of cementing the 13 3/8-in. casing; RT modeling of ESD in case of mismatch between rig calculated and measured values. In these cases the simulations provided valuable results which increased the risk awareness and prevented problems. The paper will also discuss the RT 3D Visualization and its impact on reducing risks and communicating the dynamic risk picture. The operation was successful, and the results from the simulation system was a contributor to this. Novel/Additive Information: The total simulation system with infrastructure, models and challenges will also be presented.

IADC/SPE 178863

The Use of Wired Drillpipe Technology in a Complex Drilling Environment Increased Drilling Efficiency and Reduced Well Times. R. Teelken, B. Van Burkleo, National Oilwell Varco; O. Rossa, Baker Hughes Drilling Services; S. Schils – Van Der Starre, Total Norge A/S

Objectives/Scope: This paper presents and discusses the results of a case study where Wired Drillpipe (WDP) technology was implemented on the Martin Linge offshore field development project in the North Sea for Total E&P Norge AS in Norway. Martin Linge’s resources consist of an oil reservoir and several, deeper, structurally complex, high pressure gas and condensate reservoirs. The oil reservoirs will be developed with long horizontal wells and several deviated wells will be drilled to unlock the gas and condensate reserves. The field was initially discovered in 1975 but proved too complex to develop at the time. Over the years several exploration and appraisal wells were drilled within a narrow pressure window, with multiple BHA runs per section. The complex drilling environment posed many challenges including severe losses, unstable formations and excessive downhole shock and vibrations resulting in poor MWD/LWD signal. Methods, Procedures, Process: WDP telemetry enables bi-directional, high speed data transmission to and from downhole tools at speeds up to 57,600 bps (Olberg et al. 2008). Conventional telemetry methods only provide very limited bandwidth for real-time data transmission and can suffer from signal reliability under adverse conditions, for example: no mud pulse data transmission to surface when pumps off or at flowrates below tool settings, and decoding issues during high levels of downhole shock and vibrations. WDP technology was implemented on the Martin Linge field development from the start. The technology introduction cost off-set against the quantifiable benefits for the project was calculated close to break-even. Furthermore the high upside potential associated with the use of this technology should allow improved well placement and have a positive effect on the quality of the drains drilled. Results, Observations, Conclusions: This paper will summarize how the high-speed telemetry provided by WDP enables wells to be drilled without the typical limitations imposed by conventional telemetry methods. The resulting efficiency gains and quantified time savings of the wells drilled with WDP telemetry when compared to the offset wells, drilled with conventional telemetry system, will be presented. Novel/Additive Information: The analysis will focus on two areas of efficiency and performance improvement. Firstly, the quantified data transmission time savings due to the real time high-speed transfer of critical data between downhole and surface will be discussed in detail. Secondly, the improvement in drilling performance, well placement and reservoir section length due to the real time availability of memory quality formation evaluation data and drilling data, will be discussed.

IADC/SPE 178771

Low Solids Shear Dependent Fluid System to Plugs Zones for Preventing Fluid Influxes and Losses. J.A. Urdaneta, Halliburton; K. Ravi, Halliburton; J. Pacheco, T. Joseph, Halliburton; O. Jaramillo, J. Patiño, Emerald Energy

Objectives/Scope: Lost circulation and influx from sections of high-pressure zones is a recurrent challenge and high-cost event in the oil industry, especially in mature fields or weak-fracture-gradient zones. These can significantly increase the operation cost, non-productive time (NPT), possibility of stuck pipe, and well integrity challenges. Lost circulation can be defined in a variety of ways, from partial losses to total losses, in a variety of formations, including highly-permeable, fractured, or cavernous formations. Loss circulation materials, such as particulates, can be and have been successfully used to plug smaller fractures and permeable zones. The challenge is when the losses cannot be stopped using particulates because of the loss magnitude. The industry has used various chemical solutions to overcome this challenge, with mixed results. Particulates are usually not successful in plugging high-pressure zones to help prevent fluid influx. This paper presents a low-solids loss circulation solution that develops rapid gel strength when the shear rate decreases. The gel strength buildup is based on polymers and nanomaterials in the fluid system. When the fluid enters the formation, it develops gel strength quickly because the shear rate is much lower in the formation. This helps the fluid continuously flow into the zone or be expelled from the zone. Once the gel strength has developed, the system develops nominal compressive strength to adhere to the formation and thus helps prevent displacement during subsequent well operation. The fluid is shear thinning and hence easily enters the formation zone and does not flow continuously, as it gels upon entering the formation. The low solids and low rheology under shear means that it can be easily pumped through the drillbit without having to pull out of the hole. A number of jobs have been successfully completed by pumping the solution through the drillbit. A case study from Colombia is described in this publication. Methods, Procedures, Process: In this study, the described system was pumped into a high-pressure zone to isolate an unconsolidated sand formation. Initial attempts to isolate the zone included a bradenhead squeeze job, which was unsuccessful, and fluid influx from the zone was observed during subsequent well operations. Results, Observations, Conclusions: In this study, the same characteristics described above were successful in preventing fluid influx from a high-pressure zone into the well during subsequent well operations. Novel/Additive Information: The fluid system and process described in this paper should help the industry in shutting off streaks of high-pressure zones and cure loss of fluids into the formation.

IADC/SPE 178788

Fully Mechanical Vertical Drilling Tool Delivers RSS Performance in Vertical Drilling Applications While Providing an Economical Alternative to Conventional Rotary Steerable Systems Set-Up for Vertical Hold Mode. S. Jones, C. Feddema, TurboDrill Industries; J. Castro, Scout Downhole

Objectives/Scope: A fully-mechanical vertical drilling tool has been developed to provide the economics of vertical drilling with a conventional steerable motor and the performance and borehole quality of a rotary steerable system. Through case studies, we examine the feasibility and performance of the vertical drilling system using instrumented downhole sensors. In addition, the 100% mechanical vertical-seeking control system will be explained. Methods, Procedures, Process: The fully-mechanical vertical drilling tool provides autonomous vertical control without the use of high-cost, vibration-sensitive electronics. The tool works in a “push-the-bit” configuration with four mud-operated pads located close to the bit, which continuously push the borehole wall to seek verticality. High-temperature downhole sensors and electronics were instrumented in the tool to examine the effectiveness of the vertical-drilling mechanism. Additionally, a compact, self-contained three-axis inclinometers and three-axis shock sensors were deployed in the tool (3/4-in. diameter and less than 4-in. length) to capture downhole dynamics of the tool. The vertical drilling tool was designed with improved durability for high weight on bit and high-temperature applications. It can withstand the most challenging environments while running peak drilling parameters to improve ROP (rate of penetration). Results, Observations, Conclusions: An operator drilling in West Texas was historically using steerable motors in their vertical sections, however they struggled to maintain verticality due to the high formation dips, fractured formations and faulted zones. Utilizing the vertical drilling tool allowed them to drill 6066 ft of 7 7/8-in. hole at an average ROP of 98.7 ft/hr in 61.4 hr, compared to the nearest offset wells which were taking approximately 160 drilling hr. The average inclination was maintained at less than 0.7˚, while the average inclination of the nearest offset well increased to inclinations of 3˚. To date the vertical drilling system has been used in 1,220 runs, accumulating 77,248 circulating hr and 4,072,335 ft drilled. The data retrieved from the instrumented sensors confirmed the effectiveness of the purely-mechanical verticality-control system, showing at 0.5˚. Inclinations, the tool was self-corrected to steer back to vertical. A compact downhole dynamics tool installed in the vertical drilling tool confirmed high-resolution inclination changes in various drilling conditions and revealed downhole dynamics associated with challenging vertical-drilling applications. Novel/Additive Information: A fully-mechanical vertical drilling tool has been designed and developed with 100% mechanical “intelligent” control system, which autonomously seeks verticality. Because no temperature and/or vibration-limiting electronics are used in the vertical-drilling tool, the system is rugged and durable while providing superior vertical drilling performance and enhanced ROP. Downhole instrumented sensors were used to confirm the value of the above control mechanism. A compact downhole dynamics recording device has provided new insights in challenging vertical drilling applications.

Extended Reach Drilling

IADC/SPE 178859

Long Reach Well Concept. S. Stokka, E. Cayeux, B. Aas, Intl Research Inst of Stavanger; D. Gardner, International Research Institute of Stavanger; A. Saasen, Det Norske Oljeselskap ASA; T. Larsen, Wintershall; H. Kyllingstad, IRIS FI

Objectives/Scope: Current ERD well technology is able to construct well lengths of roughly 12 km with a horizontal departure of approximately 10 km. The paper presents a concept that enables simultaneous drilling and completion with an aim to substantially extend well reach, with an ultimate objective of constructing 30-km long production wells. Longer reach wells can be used to drain remote reserves using existing production facilities as well as provide a means to access reservoirs located beneath environmentally sensitive areas. Methods, Procedures, Process: The key technology elements that enable the concept to construct long reach wells are multiple sliding packer traction units in combination with a dual casing drilling system, comprised of a casing with an inner tubing. The sliding packer traction units provide two main functions; continuous well control along the length of the borehole and traction to overcome axial friction. In addition, the traction packer units provide a stable bottom-hole drilling platform avoiding the occurrence of drilling instabilities such as stick-slip, which can damage conventional BHA’s and the drill bit in particular. The dual casing provides the conduit for drilling fluid circulation to the bit and cuttings transport to surface. The drilling fluid is pumped through the annulus formed between the casing and inner tubing. The drill cuttings are transported to surface through the inner tubing, ensuring efficient cuttings transport with a low pressure loss. Results, Observations, Conclusions: The concept has been developed through a four year project kicked off in 2010. A prototype has been built and tests have shown that each sliding packer traction unit is able to push the drill bit or pull a completion string with a force of 18 tons for the 12-in. hole version. In the paper, elements of the system are described in detail and the results of the full scale yard tests are presented. Novel/Additive Information: The concept represents a new well construction method incorporating advanced completion technology. It enables drilling and completion of long reach wells and can operate in areas with complex pressure regimes such as can occur from pressure depletion due to production or pressurizing as a result of the injection of water or gas. Well control is provided by packers placed in pairs which seal off the annulus over 100-m intervals along the drill string. Production takes place through a large inner diameter. It is a well construction method with no flat time.

IADC/SPE 178812

Drilling from Onshore to Offshore Target Reservoirs: Case Study Demonstrates Value of Diligent Planning and Systematic Execution on an Extended-Reach Drilling Campaign. G. Akinniranye, K&M Technology Group; R. Tikkoo, Origin Energy; B.N. Thearle, Origin Energy Resources; J. French, Origin Energy; S. Amin, Schlumberger; N. Goura, K&M Technology Group

Objectives/Scope: An operator in the Halladale field, offshore Australia, completed its first extended reach drilling project from an onshore location to access offshore targets. The Halladale gas field is located up to 5.5 km offshore and up to 1.8 km below the seabed. The proximity of this and the adjacent Speculant prospect to the coastline enabled the operator to drill wells from onshore using extended reach drilling (ERD) techniques. Methods, Procedures, Process: To mitigate depth uncertainty at the target location, an S-shaped trajectory was selected starting with a shallow kickoff followed by a sub-horizontal section that traveled laterally offshore and ended with a dropoff section to intersect the reservoir target. Advanced drag management techniques were required to install the 9 5/8-in. production casing, 7-in. production liner, and 5 ½-in. intelligent upper completion. The 9 5/8-in. casing was installed using the buoyancy-assisted method (i.e., “floatation”), such that it could be “pushed” and “reamed” in the hole beyond the point of negative weight. As a result of the successes achieved to date, the operator is now exploring drilling longer reach prospects up to 8 km from the onshore drill site. Results, Observations, Conclusions: Technical challenges were overcome and well design solutions and operational practices were developed with the aid of modeling and simulations performed during well planning. The preparation of comprehensive well programs, the use of real-time data to validate the models that were implemented, and the systematic approach to well planning contributed to the success of the project. In addition, a process was adopted to ensure that every member of the team understood the program and was committed to the successful delivery of the wells. These measures resulted in significant project cost savings. The first of the extended reach wells was drilled and completed 16 days ahead of schedule and approximately $7 million below budget. Novel/Additive Information: The 9 5/8-in. casing was run completely empty and required rotation in order to reach TD, however, during the operation of landing-out the casing on the well head, the use of rotation to overcome axial drag was not an option, and adequate contingency planning was required. A casing selective floatation collar was installed to provide additional weight if required by filling the top portion of the string with drilling fluid as TD was approached, but allowing the lower portion of the casing in the high angle interval of the wellbore to remain empty, allowing the drag required to slack the string off and land out the casing to be minimized. This contingency was in addition to the available push-down weight that the top drive could provide, which also formed part of the risk management plan that was in place.

IADC/SPE 178801

Planning, Collaboration and Optimized Drilling Performance for Drilling Extended Reach Wells in the Bakken/Three Forks. N. Nair, P. Bitzan, Halliburton; F. McRobbie, Enerplus Resources (USA)

Objectives/Scope: This paper discusses the methodology involved in evaluating the risks associated with drilling extended-reach wells using conventional drilling tools and adopting a stepped approach towards the drilling optimization of 25,000-ft TD wells, with horizontal legs exceeding 14,000 ft. Extensive planning was carried out over the following areas of the project: well-trajectory design, torque and drag, the fluid program, drilling practices, drillstring design and integrity, hydraulics management, drilling optimization tools, and BHA design. Methods, Procedures, Process: The objective was to drill two extended-reach wells in the Bakken and Three forks formations in North Dakota and to use the lessons learned to drill three additional wells with 50% percent longer laterals. The first two wells of the project were studied to calibrate torque-and-drag models for hole friction, drillstring dynamics with the effects of fluid in-hole drag, effects on ROP with regards to weight transfer while sliding, hydraulic effects of the fluid system, motor output, vibrations analysis, drilling practices through transitions, and parameter optimization while drilling through formation markers through the horizontal leg of the well. Results, Observations, Conclusions: The first two wells were drilled using a drilling-optimization down-hole tool placed above the motor that measures the weight, torque and bending moment across the sub, and the pressure while drilling tool. Tri-axial vibration sensors were used to measure and transmit data in real time to optimize drillsting dynamics and make improvements in the drilling system post run. The improvements in the system and lessons learned were used while three additional extended-reach wells with measured depths over 25,000 ft. Drillstring dynamics from the down-hole sub were studied to identify ways to overcome friction. The data validated the effectiveness of certain friction-breaking tools and proposed areas for improvement in order to orient drill with conventional motors further into the lateral. The limitations with the current system were identified with the first two extended-reach wells. Wellbore-trajectory design and pipe placement were optimized to aid in transferring weight to the bit beyond the 10,000-ft lateral horizontal leg. Alterations in the drilling program were subsequently made to drill further into the lateral based on lessons learned from down-hole optimization tools and surface sensor data. Novel/Additive Information: Three wells were drilled beyond a 25,000-ft total measured depth, with the horizontal leg exceeding 14,500 ft in the lateral. Continuous improvements were made to the system to drill to the limit with conventional motors and to pick up sophisticated rotary steerable tools to drill the last 1,500 ft of the lateral. The approach proved more cost effective to optimize within the constraints of the drilling system before using sophisticated rotary steerable tools.

IADC/SPE 178785

Improved Ecd Prediction And Management In Horizontal And Extended Reach Wells With Eccentric Drillstrings. O. Erge, The University of Tulsa; A. Karimi Vajargah, The University of Texas at Austin; M.E. Ozbayoglu, University of Tulsa; E. van Oort, The University of Texas At Austin

Objectives/Scope: Accurate prediction of Equivalent Circulating Density (ECD) plays a vital role in hydraulic pre-planning and real-time management of drilling operations. Such accuracy is often not available in case of drilling horizontal and extended reach wells, when there is a partially or fully eccentric annulus in a large section of the wellbore. Many hydraulic models, including those widely used in the industry based on e.g. the Narrow Slot approximation, simply ignore the effects of drillpipe eccentricity on annular pressure loss and equivalent circulating density (ECD), thereby generating unreliable estimates for these important quantities. Methods, Procedures, Process: In this study, we discuss the experimental, analytical, and numerical results of a comprehensive investigation into the impact of drillpipe eccentricity on ECD in horizontal and extended reach wells while circulating non-Newtonian drilling fluids. A 91-ft long flow loop with a drillpipe-to-hole/casing ratio of 0.5 (fairly common in conventional drilling applications) was used for the experimental investigation. Drillpipe was placed at the bottom of the hole/casing, thereby simulating a fully eccentric annulus. Four realistic non-Newtonian drilling fluids, which their rheological behavior best described by the Yield Power Law (YPL) model, were used as test fluids. Moreover, a novel numerical model based on a Computational Fluid Dynamics (CFD) approach was developed. Subsequently, the experimental data was compared with both the new proposed model as well as with several other widely used analytical and numerical models previously reported in the literature. Results, Observations, Conclusions: The experimental results confirm – and add to – the historical observations that the annular frictional pressure loss in a fully eccentric annulus is significantly less than the values predicted by the Narrow Slot approach, sometimes by more than 50%. In general, all the evaluated models under-estimated the effect of drillpipe eccentricity on annular frictional pressure loss. However, by comparison, the newly proposed model in this study exhibited by far the least discrepancy with the experimental results. The difference between the estimated and experimental results was found to be proportional to the magnitude of the fluid yield stress and consistency index, and attributed to the complexity associated with simulating YPL fluids. Novel/Additive Information: This study provides valuable insight towards superior hydraulic planning and real-time ECD management in horizontal and extended-reach wells. Its beneficial impact on managing the annular pressure between the fracture and pore pressure in the field to prevent drilling problems such as kicks, mud loss and wellbore instability events is expected to be immediate. Its use will also be key to successful implementation of innovative drilling techniques such as managed pressure drilling and dual gradient drilling, which require highly accurate annular pressure prediction and management.

IADC/SPE 178905

Friction Load Redistribution for Robust and Cost Efficient Design of Extended Reach and Horizontal Well Completions. A.R. McSpadden, R. Trevisan, Altus Well Experts.

Objectives/Scope: In horizontal and extended reach wells where long completions are run into highly deviated or lateral zones, large compression loads arise due to running friction. These loads remain locked into the string when the packer or cement sets. Dissipation of friction during life service due to string vibrations and movements redistributes these friction loads between the wellhead and packer. A numerical approach is presented to correctly calculate the redistributed friction load so that an accurate initial tubing load is implemented in the tubular stress analysis. The proposed methodology offers an opportunity for tubular cost savings by accurate estimation of the stress regime when running friction is locked-in during completion but later dissipates. Methods, Procedures, Process: The numerical approach is a simple 1-D finite element model in which incremental frictional loads are decomposed and redistributed based on relative stiffness of the string uphole and downhole of each local node. Essentially each portion of the string is represented as a series spring system. The methodology requires input of the estimated friction load during running from a standard torque-drag analysis. An analytical solution derived for a simple configuration with a build and hold trajectory is used to validate model accuracy. Results, Observations, Conclusions: The results are particularly relevant for ERD and shale-type multizonal lateral wells, where overestimation of in-service compression above the packer or cement may pose considerable design challenges for tubular components including connections. The common assumption to ignore friction in tubing analysis is non-conservative in that it may underestimate friction loads, especially downhole at the packer. However applying the full slackoff load downhole is also unrealistic and overestimates compression above the packer leading to costly component selection. Results from the numerical model wherein post-dissipation friction loads are redistributed show that only a part of the friction induced compression migrates to the packer. Some of the redistributed friction load results in additional tension at the wellhead. The type of trajectory, kick off depth and deviation angle are important for the load redistribution. Results from a sensitivity study provide some possible guidelines and recommendations. Comparison of the numerical solution with the analytical solution demonstrates that the accuracy of the numerical model depends on the element mesh spacing. Novel/Additive Information: The methodology presented in this work provides an approach for accurate calculation of the amount of friction load transferred to the completion above the packer. The redistributed result which divides the running friction load between hanger tension and downhole compression is not intuitive. This is critical for correct modelling of the initial conditions in the tubing stress analysis with significant impact on tubular cost efficiency and fit-for-purpose design and well integrity.

IADC/SPE 178792

A New Friction Reduction Tool with Axial Oscillation Increases Drilling Performance: Field-Testing with Multiple Vibration Sensors in One Drill String. S. Jones, C. Feddema, Turbo Drill Industries

Objectives/Scope: Weight transfer problems, hanging-up, poor tool face control and diminishing ROP are all problems that are encountered with steerable motors in high angle and horizontal wells. A number of oscillation and/or vibration devices have been introduced to the market over the years to aid these common problems. Both axial oscillation and lateral vibration tools have proven to provide improvements to drilling performance and toolface control. But, as with any device there are always limiting factors, and oscillation and/or vibration devices can cause unwanted vibrations that interfere with MWD systems and even cause component failures. This paper describes the operation and field test results from a new axial oscillation tool. Key component in the string were instrumented to gather critical information on vibration frequency levels throughout the BHA in an effort to optimize system performance. Methods, Procedures, Process: The new oscillation tool uses a mud valve to generate pressure pulses in the string. These pressure pulses are magnified using a specifically designed stroke tool referred to as an intensifier. The mud valve is driven with a short power section from a Positive Displacement Motor (PDM). The lobe configuration of the power section along with nozzle size allows the frequency of the tool to be varied to optimise system performance and reliability. The system was tested with specific MWD systems in a flow loop prior to going downhole to confirm compatibility. The oscillation tool has been designed to be durable over long horizontal runs. A compact, self-contained three-axis inclinometers and three-axis shock sensors (3/4-in. diameter and less than 4-in. length) have been deployed during field testing to capture downhole dynamics. These sensors were strategically positioned in the BHA to gain understanding of vibration propagation distance/pattern and vibration frequency changes over the course of the run. Results, Observations, Conclusions: The data received from the downhole instrumented oscillation tool provided valuable information on drilling dynamics over the course of the field test runs. This data will be discussed and correlated to improvements made during the course of the field test. Strategically deployed vibration recording sensors in the BHA revealed the characteristics of the axial excitation generated from the oscillation tool. This data was used to optimize BHA and tool placement to maximize drag reduction. The new oscillation tool has proven to provide the performance improvements and economics required to compete in this expanding market to aid slide drilling. Novel/Additive Information: Downhole instrumented sensors were used to confirm the value of the axial oscillation mechanism. The use of multiple compact downhole dynamics recording devices has provided new insights in challenging steerable motor drilling applications, assisted with a friction reduction tool.

Deepwater and Subsea

IADC/SPE 178820

Subsea Driving of Conductors: a Cost Effective and Successful Alternative to Pre-drilling on Moho Nord TLP Development. G. Navez, Total E&P Congo

Objectives/Scope: The proposed paper will address the subsea driving of 27 conductors in 800 m water depth offshore Congo, in preparation of the drilling operations from the Moho Nord Tension Leg Wellhead Platform (TLWP). The objectives of the paper are to present part of the experience gained on this project, in particular the reasons for selecting this alternative to pre-drilling of the Conductors in deepwater and some of the main planning, engineering and operational challenges encountered, so as to help preparing and delivering future similar projects in due time, on cost, and without jeopardizing the subsequent drilling operations. Methods, Procedures, Process: The methodology will be that of a case study, described from the perspective of the operator’s drilling entity and in a mostly chronological fashion, from the selection of the installation method to the operations. The main challenges encountered during the project and the solutions found will be addressed, including but not limited to a decision-making process based on technical-commercial data and an engineering process combining geotechnical and mechanical (FEA) analyses. Results, Observations, Conclusions: The selection of this installation method is primarily linked to the significant direct cost savings it allowed in a situation where planning (rig & installation vessel availabilities) and the development specificities (semi-tender assisted drilling from TLP with asymmetric surface/subsea patterns) made the jetting alternative not applicable and the pre-drilling unappealing while synergies with other project entities put the driving method forward. The novelty of using this method for subsea wells led to specificities in the conductor design and engineering, including tubular geometry, connections (pipe-to-pipe welds) and conductor housing, mainly due to the fatigue accumulated during the driving operation but also following specific geometrical and mechanical requirements linked to the installation equipment and procedures (vent holes, driving shoe, shims, etc.) Interfacing among drillers, equipment providers and offshore installation professionals, each with their technical knowledge, constraints and limitations, led to re-engineering of existing equipment (conductor housing) and the design of adapted lifting/handling tools. The actual driving campaign took place as planned and with success in Q4 2014. The actual drilling operations on the Moho Nord TLWP are planned to start in Q1 2016. Novel/Additive Information: Whereas conductor or pile driving has been used extensively in other applications and/or industries (shallow water drilling, offshore construction, etc.), its use in deepwater drilling operations with subsea hydraulic hammers and wellhead systems is recent and the published knowledge accordingly scarce. This paper will add to the body of knowledge by providing offshore development project managers & engineers with first-hand information about this alternative to jetting conductors, its potential benefits, and key engineering and operational challenges to be considered to make it a success.

IADC/SPE 178827

Reduce P&A Cost with Section Milling Technology. T. Ghegadmal, A.D. Ponder, Baker Hughes

Objectives/Scope: Section milling technology is over 50-years-old. Before sophisticated sidetracking systems were invented, a section mill was commonly used to mill away a 75 to 100 ft section of casing to set a ramp for the drilling assembly to sidetrack into the formation. For stabilized milling, section mills were sized close to inside diameter of the casing to be milled, and knives were extended far enough to mill a single casing string. Methods, Procedures, Process: There are times when milling a section of casing must be accomplished below a restriction. In these applications, multiple stabilizing arms are extended along the mill to centralize it inside the casing. Then, cutting knives are extended to cut through the casing wall and mill down, removing the unwanted casing section. Stabilizer arms keep the mill firmly centralized inside the casing being milled. Results, Observations, Conclusions: Recently, such a section milling system was used to plug and abandon (P&A) subsea wells, which required removal of multiple casing strings. The P&A cost of several of these wells in the Gulf of Mexico (GoM) was substantially reduced by using this new section milling system for removing casing which had an inside diameter larger than that of the production riser. The results were substantial, with three days saved on one well, saving the operator approximately $1 million. This was accomplished by leaving the riser, blowout preventer (BOP), and swarf handling equipment in place. Novel/Additive Information: This new section milling system has significant advantages over the conventional system. A full 90˚ extension of knives and stabilizer arms provides greater reach for reliable milling of an intermediate or outer casing string, after conveying the mill through the innermost casing string. A unique method of extending and retracting the milling knives and stabilizer arms provides reliable operation. State-of-the-art tungsten carbide cutting inserts improve milling performance significantly. The knife’s greater reach gives unobstructed access to the mill and eliminates individual runs ordinarily required for removal of multiple casing strings, production riser, BOP stack and other surface equipment, substantially reducing costs and HSE risks. Case histories of offshore applications of this new technology will be presented.

IADC/SPE 178856

A new Method for Determination of Stress and Fatigue in Risers and Wellheads. H. Horn, Ferrx as; A. Saasen, Det Norske Oljeselskap ASA; A. Skogvang, Lundin Norway AS

Objectives/Scope: The scope of the paper will be to present a new and patented non destructive technique for measuring deterioration and cracks in steel structures. Results from stress and fatigue tests with different full scale structures will be presented and related to real applications with respect to life time prediction. Methods, Procedures, Process: The method monitors stress and deterioration in ferromagnetic steel. The material properties magnetic permeability and electrical conductivity and changes in these are determined by analyzing the measured voltage response to injected current pulses. The response is transient voltage drop signals, measured under various conditions, and are the basis for calculating the parameters representing the stress, fatigue and crack nucleation and crack development in the materials. Degree of material degradation can be used to characterize used degree of operational lifetime. Results, Observations, Conclusions: The method has been tested and verified for different types of stress and fatigue in different steel alloys. High sensitivity to elastic stress and early detection of permanent changes for high-cycle fatigue testing have been demonstrated e.g. with fatigue tests of work over riser pipes. High sensitivity to remanent stress, i.e. the steel’s ability to “remember” stress (elastic) is a feature that is proportional to maximum stress since last measurement. This is valuable information when monitoring e.g. steel risers. On risers it can be installed on selected location to give the actual condition in the steel for the most exposed locations and use this information to calibrate the mathematical models used to estimate the condition of the whole riser and by this reduce estimated uncertainty. The technology’s ability to monitor the actual stress and fatigue development in wellhead casing pipe has been described. Novel/Additive Information: A new method is presented which will significantly reduce uncertainty related to the condition of monitored subsea structures. This method provides for directly measurement of actual material deterioration which can lead to fatigue in e.g. steel risers or wellhead pipes, and can predict any crack initiation or fatigue development.

IADC/SPE 178907

A Reliability-Based Approach for Survival Design in Deepwater and High Pressure/High Temperature Wells. P.V. Suryanarayana, D.B. Lewis, Blade Energy Partners

Objectives/Scope: We present a reliability-based approach to demonstrate well integrity under survival load scenarios, which are increasingly driving well design in critical deepwater and HPHT wells. It is shown that the current practice of using standard working stress design for survival scenarios, even with design factors approaching unity, fails to quantify risk of failure, and can lead to design practices and outcomes that are not risk consistent or optimal. A probabilistic, limit-state based approach is therefore necessary to adequately demonstrate integrity and risk under survival scenarios. Methods, Procedures, Process: The paper describes Reliability based design (RBD) and its use in other structural design codes, and shows how it can be used for survival design in critical wells. A distinction is made between operating (service) loads and survival loads. Particular attention is given to Worst Case Discharge and Well Containment loads, which have become design-dictating survival loads in many deepwater well designs. A probabilistic approach in which a deterministic load at its extreme survival magnitude is compared to stochastic strength (from data on strength parameters) is presented to address survival design. Regardless of how low the probability of occurrence of the load is at its survival magnitude, well integrity is demonstrated assuming such a load occurs. The method can be easily implemented by constructing resistance distributions using limit state equations such as the Klever-Stewart Rupture Limit, and the Klever-Tamano Collapse Limit equations, with strength parameter data from API TR 5C3 (ISO TR 10400), manufacturer reports or direct measurement. Statistical approaches to constructing such distributions are presented. Results, Observations, Conclusions: The goal in survival design is to demonstrate survival rather than continued operability. The probability that the deterministic survival load exceeds the stochastic resistance is used as the basis for demonstration of survival. Based on this, acceptable probabilities of failure for typical survival loads are recommended, and contextualized to other design codes. The applicability of this approach to connection selection and brittle failure is also demonstrated. Deepwater and HPHT well examples are presented to illustrate the use of the approach. It is shown that designing to an acceptable probability of failure leads to more robust and risk-consistent designs in critical wells. Further, such an approach allows designers to focus on the specific design or well construction changes that enhance survival. Novel/Additive Information: The approach described in this paper provides a quantitative basis to examine design adequacy of wells under survival scenarios, particularly worst-case discharge and well containment loads. Using stochastic strength data rather than deterministic strength estimates provides a probabilistic basis for design, thus quantifying risk, and allowing more informed decision making. The authors believe this is a much needed, rational approach to optimize design of critical wells under increasingly demanding loads.

IADC/SPE 178835

Differentiate Drilling Fluid Thermal Expansion, Wellbore Ballooning and Real Kick during Flow Check with an Innovative Combination of Transient Simulation and Pumps Off Annular Pressure While Drilling. Z. Yuan, Schlumberger; D.R. Morrell, Schlumberger Information Solutions; A. Garcia-mayans, Schlumberger D&M

Objectives/Scope: To achieve a high level of drilling efficiency, it is paramount to correctly identity reasons of drilling events from available data in a timely fashion. Many surface or downhole events share common root causes. Drilling fluid thermal expansion, wellbore ballooning and formation kick share similarities in terms of surface observation such as pit gain volumes. However, resolution for each of them is completed in a totally different manner. Treating a wellbore ballooning effect in the same way as a kick will likely result in losing the current borehole after days or weeks of unsuccessful operations. Methods, Procedures, Process: In this study, pressure while drilling technologies and software simulations are discussed to analyze variances in the wellbore parameters over time to investigate drilling fluid thermal expansion, wellbore ballooning and formation influx during flow checks in riserless drilling operations. A transient simulation software was used to study the fraction of gas in the annulus and fluid level inside the drillstring on several flow checks following flow and gas bubbles at the well head. Availability of continuous pumps off annular pressure while drilling measurement helps calibrate the simulations and verify its validity. Results, Observations, Conclusions: A new workflow combining modelling, simulations and downhole annular pressure profiling measurement was successfully applied to a riserless pilot hole deep water well Gulf of Mexico. The flow contribution from each drilling fluid thermal expansion, wellbore ballooning, formation influx and u-tube flow was identified and decomposed. Novel/Additive Information: Transient flow simulator working together with pressure while drilling data gave the operator an exact knowledge of wellbore dynamics in an operation usually performed with limited information. This proved extremely valuable in the pursuit of drilling prospect.

Tubulars

IADC/SPE 178858

A New Sour Service 125 ksi SMYS Drillpipe with Sour Service 120 ksi SMYS Tool Joints For Use in Sour Gas Drilling or Non-Sour Offshore Intervention Riser Applications Requiring Higher Load Capacities. A. Uttecht, National Oilwell Varco; M.J. Jellison, L. Hehn, NOV Grant Prideco; L.W. Sanclemente, M. Delahoussaye, Workstrings International

Objectives/Scope: The term “sour” is used to refer to drilling environments containing hydrogen sulfide (H2S). In sour wells, H2S causes sulfide stress cracking (SSC) in carbon low-alloy steels under tensile stress. A form of hydrogen embrittlement, SSC causes sudden, brittle fracture in drillpipe. To combat the effects of H2S exposure, sour service drillpipe has been manufactured to meet IRP Volume 1 – Critical Sour Drilling specifications. IRP requires SS75 ksi, SS95 ksi, or SS105 ksi specified minimum yield strength (SMYS) tubes with all three grades using 110-ksi SMYS tool joints for use in sour operations. However, these lower yield strength IRP grades have limited load capacity which restricts drilling parameters such as total depth (TD) and margin of overpull. Methods, Procedures, Process: Using advanced steel heat treatment methods, a 125-ksi SMYS grade sour service drillpipe has been developed. The 125-ksi tube is mechanically incompatible with the standard 110-ksi IRP sour service grade tool joint because of the large difference in yield strength between the two components. Therefore, a new class of sour service tool joint with an SMYS of 120-ksi was required for the 125-ksi sour service tube. This new higher yield strength tool joint needs to meet the same level of SSC-resistance as the 110-ksi IRP tool joint, i.e., pass testing in solution A method A of NACE TM0177 (100% H2S at pH = 2.7, 720-hr test) at a testing stress of 65% of SMYS. Like the high yield strength 125-ksi tube, advanced heat treatment methods were required to achieve SSC-resistance in the higher yield strength tool joint. Results, Observations, Conclusions: A second application for the 125-ksi drillpipe is as an offshore drillpipe-based intervention riser for non-sour wells. Currently, 105-ksi drill pipe grades are often used but increased demands on load capacity (up to 1,000 kips) makes the 125-ksi drillpipe an attractive alternative. The 125-ksi drillpipe also meets recommended hardness limitations placed on offshore risers in specification API RP 17G (Recommended Practice for Completion/Workover Risers). Novel/Additive Information: This paper introduces an SSC-resistant 125-ksi drillpipe with SSC-resistant 120-ksi tool joints and presents the results of NACE TM0177 testing of this new technology. The new 125-ksi drillpipe will allow for increased load capacity over IRP SS105 ksi grade drillpipe in drilling environments with moderate to low concentrations of H2S. In addition, it can serve as an improved substitute over 105-ksi drillpipe-based offshore intervention risers due to its increased load capacity and controlled hardness.

IADC/SPE 178823

Increasing Long-Term Fatigue Performance of an API Box Boreback Using an Enhanced Non-Truncated Thread Design and Revised Machining Methodology. G. Hauze, S.R. Gokhale, T H Hill Associates

Objectives/Scope: Stress Relief Features (SRF) are commonly added to a Rotary Shouldered Connection (RSC) to increase the fatigue performance of the connection. An SRF aims to lower critical stress at the last engaged thread and improve fatigue performance. The most common SRF found on API box connections is the API Box Boreback. Methods, Procedures, Process: The API Box Boreback SRF is added to an API RSC by boring out both box threads and ID to a specified cylinder diameter and depth from the box shoulder. The API boreback is then finished by profile turning a tapered transition of specified angles and lengths which connects the back of the boreback cylinder to the ID of the component. The traditional method of boring the cylinder diameter due to the tapered threads of API connections causes a removal of thread crests at the back of the box. These truncations of the last engaged threads reduce the contact area of the thread flanks available to support the load. The repercussions of this include an increase in stress concentration, reducing fatigue life, and an escalation in susceptibility to thread wear, which inevitably amplifies the effect of the thread truncation, further reducing the fatigue life and cancelling out the benefits of the SRF. Details of this phenomenon can be found in IADC/SPE128931 (Gerdes&Lee 2010). Results, Observations, Conclusions: Despite its popularity, the API Box Boreback SRF can lose its effectiveness as the thread truncation at the back of the box can accelerate crack initiation and cause premature failures. To remedy this, an experimental study was undertaken to develop a machining method to cut a boreback with an enhanced non-truncated geometry on API box connections. The modified boreback geometry and machining methodology were perfected over multiple iterations, prototyped with a Computer Numerical Controlled (CNC) lathe using various routines and tooling selections. The dimensions were verified to conform to the requirements outlined in API Specification 7-2 and the machining process was validated on multiple API box connection types. Novel/Additive Information: This paper presents details of a modified design and a universal machining methodology developed to cut an API compliant Box Boreback which retains full-height threads at the back of the box, avoiding thread truncation, and preserving the increased fatigue performance a Box Boreback provides well into the life of the connection. The method meets all dimensional requirements outlined in API Specification 7-2, ensuring proper makeup. The machining process can be performed on either a CNC or manual lathe. The enhanced boreback design provides a drastic improvement in fatigue performance over the standard API Box Boreback design, while maintaining all other structural and dimensional design aspects, and without altering Makeup Torque (MUT) or Bending Strength Ratio (BSR) of the connection.

IADC/SPE 178833

Casing Wear: Is it an Enigma or a Conundrum? R. Samuel, Halliburton

Objectives/Scope: This paper examines the current state of casing-wear modeling and simulation and identifies the complexity involved. As more and more complex wells are drilled, an important problem to be addressed is related to casing wear, more specifically, the casing exposed to production. Casing wear is one of the continuing challenges faced by the industry, and an accurate estimation of downhole wear remains a paradox. Methods, Procedures, Process: Presently, there are no guidelines available in the industry, as the severity is felt after long-term production. Short-term effects of improper estimation of casing may not be felt owing to the overdesign of the casings by largely applying excessive safety factors. Various casing-wear estimation techniques have been proposed; however, the accuracy of the models developed is questionable, and companies rely on the outdated model and wear factors. The paper proposes new model and guidelines by integrating the model and wear factor estimation. Results, Observations, Conclusions: This paper aims to bridge this existing knowledge gap and provides a comprehensive treatise on casing wear and, more in general, tubular wear estimations and their underlying model parameters. The paper describes the details and the new calculation methodology of position wear around the casing using the stiff-string method. The wear factors are inherently tied to the friction factor in the modeling process. This paper investigates in detail the dependency of the casing-wear factors on these uncertainties through several example calculations and presents an extensive analysis on the results obtained. It provides a simple set of guidelines to help understand the fundamental concepts for better downhole-wear estimation. An accurate prediction of casing wear is essential to enhance well integrity and further the life of the well. Hence, the paper presents specific examples for casing-integrity analyses and provides recommendations to improve the overall well integrity. Novel/Additive Information: This paper provides a sound engineering basis for future drilling engineers to effectively understand the challenges involved in estimating and quantifying casing wear. The methodology presented in this paper is validated with a scalable mathematical model. The paper provides in-depth understanding of the casing-wear position based on contact points using the stiff-string model. The coupled engineering model provides a basis for well-integrity analysis.

IADC/SPE 178806

Collapse Strength of Casing Subjected to Combined Loads. J.F. Greenip, Viking Engineering

Objectives/Scope: Triaxial evaluation of loads is used extensively for casing and tubing string design and analysis. The paper, proposed for the Tubulars – Production Tubulars technical category, presents a more accurate method of determining the collapse strength of casing and tubing subjected to simultaneous axial and internal pressure loads. It will be shown that casing and tubing subjected to combined loads have higher collapse design factors than current calculation methods predict. Methods, Procedures, Process: A triaxially based formula is presented that simultaneously incorporates internal pressure and axial load into the calculation of casing and tubing collapse strength. The formula is compared to the existing First Edition API TR 5C3 uniaxial method of accounting for internal pressure. The paper compares both the existing uniaxial method and the new triaxial method with API combined load collapse test data, further validating the triaxially based formula. Casing design examples contrast the existing method with the triaxially based method, showing the higher collapse design factors calculated when using the more accurate triaxially based formula. Results, Observations, Conclusions: The First Edition API TR 5C3 formula for calculating the effect of internal pressure on collapse fails to account for the contribution of instability to collapse of higher diameter-to-thickness ratio pipe. In addition, the current effect of internal pressure on collapse formula inaccurately assumes uniform stress across the wall and the formula is inconsistent with moderate and thick-wall stress theory. The paper augments existing First Edition API TR 5C3 formulas for calculating collapse strength in the presence of internal pressure plus axial loads. The triaxially based method generates higher collapse design factors when internal pressure is present. Novel/Additive Information: Common existing graphical methods of triaxial analysis for OCTG do not permit incorporating internal and external pressure simultaneously. The paper provides improved depiction of the triaxial stress state and reflects the impact of combined loads encountered in oil and gas well applications. OCTG string design is improved using the method presented.

IADC/SPE 178791

Casing Integrity: Modeling Strength Degradation. C. Li, University of Houston; R. Samuel, Halliburton

Objectives/Scope: Casing integrity management is of critical importance especially in wells experiencing severe casing wall degradation. It is highly desirable to predict the threshold pressure for degraded casing burst and collapse strength, and design the casing strings considering these wear effects. Knowledge of stress distribution in worn casing helps predict where casing failure occurs first. This study focuses on building a model for stress distribution along casing circumference based on “crescent shape” casing wear. Methods, Procedures, Process: A common method is to estimate the reduction of the casing burst strength in worn casing using API burst strength equation with a linear reduction by the remaining wall thickness or wear percentage equivalent to a “uniform-worn” casing model. However, this approach can be too conservative, resulting in higher costs because of overdesign of the casings. This paper presents a rigorous engineering method to calculate the hoop strength directly, including the local bending in the thinner portion of the “crescent-worn” casing. Results, Observations, Conclusions: A model and correlation to calculate varying hoop strength in the crescent worn shape and non-worn casing have been developed with force and moment balance equations. This paper further delves and builds equations for stress distribution at every section along the circumference in the near critical scenario. The study finds the calculation of strength using the linear wear model to be overly conservative because it only focuses on the stress at the thinnest portion of the worn casing. The study based on the variable worn cross section provides stress distribution at every section along the circumference in the near critical scenario. The hoop strength varies with the angle of the cross section showing that hoop strength increases with the casing wear. It is also observed the hoop strength almost remains constant in the non-wear part of the casing. In addition, hoop strength decreases with the increasing of the half angle of the casing wear part. Novel/Additive Information: The stress predicted in this paper is similar to results obtained from the finite element method (FEM), which validates equations and results obtained from this paper. Simple guidelines presented along with several example calculations using von Mises failure criteria help illustrate the improved tubular modelling aspects. The developed model is generic and can be used for casings, risers, and tubings.

IADC/SPE 178861

Buckling of Tubular Strings in Open Sea. A. Kyllingstad, National Oilwell Varco

Objectives/Scope: An analytical model for steady state lateral buckling of tubular strings is presented. It applies both for drill strings during riser less drilling of top holes and for marine risers. The model represents a tool for predicting critical compression force at the lower end and also critical shortening length of the buckled string in situations when the top site heave compensation or tensioner system fails. Methods, Procedures, Process: The static lateral deflection of the string is described by a fourth order differential equation that can be linearized for small inclinations. Non-trivial analytic solutions include homogeneous and inhomogeneous Airy functions that can be combined to satisfy various boundary conditions and shortening lengths. The effect of a side force is also included in the solutions. The paper discusses the validity of the underlying assumptions, such as linearity, simplified boundary conditions, and the neglecting of dynamic effects. Finally, the theory is also compared with experimental results from a small scale physical model. Results, Observations, Conclusions: Analytically derived formulas are valuable because they provide physical insight of the buckling phenomenon. They can explicitly tell how the buckling load varies with various string properties, such as diameters and length. As an example, the presented theory predicts that both deflection and stress increase proportionally to the square root of the shortening length. Another formula shows that maximum stress is nearly independent of the string length. This is at least true when the length exceeds a few characteristic buckling heights, defined as the cube root of the ratio of bending stiffness divided by the effective buoyant weight per unit length. An important result from the analysis is that a drill string will survive rather large accidental shortening lengths without being plastically deformed. The analytic solutions are successfully compared with the deflection of a small scale physical model having a characteristic buckling height scale of 1:185 as compared with 6 5/8-in drill pipes. The good fit between theory and experiments strongly support the validity of the analytic solutions. Novel/Additive Information: The presented theory provides simple formulas that can be used by engineers to predict critical compression force and critical shortening of tubular strings, such as drill strings and risers in open sea. It can also serve as static benchmark solutions to more advanced numerical and dynamic models.

IADC/SPE 178777

Landing String: Breaking the 2.5 Million Pound Limit. G. Plessis, NOV Grant Prideco; R. Verhoef, S. Ringstad, A. Pangilinan, NOV

Objectives/Scope: With operating companies moving into deeper prospects, it is becoming increasingly more challenging to land heavy casing strings. Solutions are referenced in published papers focused on the optimization of specific aspects of the overall operation. To date, these solutions are used for casing landing operations running up to 2.5 million pounds (1,250 sTon), which is the hoisting capacity of most offshore mobile drilling units. A trend has been established in the oil and gas industry where more frequent requests are being made for landing strings of higher tensile capacity, with ratings of 2.75 or even 3.0 million pounds. Reaching this level of tension in a string is demanding in terms of its own design but also presents additional challenges when it comes to hoisting it on the rig, sitting it on slips, torquing it, and being able to shear it with the BOP if quick disconnect is necessary. This paper focuses on that challenge. Methods, Procedures, Process: This paper addresses the impact of design choices and shows the best options the industry can use at every landing string interface. Often, the system components are selected in isolation bringing partial answers to this industry’s challenge; the true answer goes beyond this and is an integrated solution. The impact that design choices have on capacity are discussed and an integrated solution was developed that focuses on every landing string interface. Results, Observations, Conclusions: This paper presents an array of technologies that allow operating companies to safely run casing string weights greater than what is run today and can serve as guidelines for drilling engineers as they plan deeper prospects. Novel/Additive Information: The challenge is to understand the interactions of these technologies to create a balanced system that leads to safer landing operations.

Directional Drilling

IADC/SPE 178831

Effect of Transient Surge Pressure on Stress Distribution around Directional Wellbores. Z. Zamanipour, S.Z. Miska, University of Tulsa; P.R. Hariharan, Shell

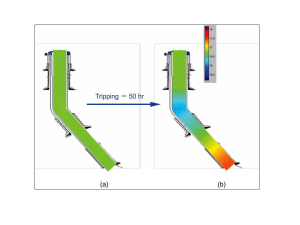

Objectives/Scope: Fluid displacement due to pipe movement into/out of the wellbore generates surge/swab pressure. Surge/swab pressure could result in formation fracturing, lost circulation, kicks, and even blowouts. Transient surge pressure depends on tripping velocity, mud viscosity, fluid compressibility, wellbore expansion, and elasticity of the drillpipe. Considering wellbore stability, sudden pressurization of the wellbore due to surge pressure causes rapid change in stress distribution in the zone near the wellbore that may result in wellbore instability. Therefore, it is necessary to have an estimation of transient surge pressure and stresses for safe and effective tripping operations. Methods, Procedures, Process: In this work, for the first time, stress distribution and the stability around the wellbore are being investigated when transient surge pressure is generated in the wellbore. Firstly, a transient surge pressure model is developed to calculate the pressure along the wellbore during the tripping-in operation. The model is based on transient wave propagation due to fluid compressibility and wellbore expansion. Then, the following steps are taken to obtain stresses around the wellbore: 1- Stress distribution around directional wellbore is calculated based on poroelasticity concept. 2- Induced pressure and stresses due to constant borehole pressure change are calculated. 3- Induced pressure due to transient surge pressure is calculated using Duhamel’s theorem. 4- Induced stresses are calculated and added to existing stresses around the wellbore using superposition principle. Results, Observations, Conclusions: The model is implemented for tripping into a directional wellbore with a trapezoidal velocity profile. The induced pressure, radial and hoop stresses versus radius are calculated at different times. Results show that induced pressure vanishes almost completely at a distance of about six times the wellbore radius. Induced pressure increases with time until it reaches its maximum which is the maximum of surge pressure and then dissipates with time. Induced pressure peak propagates into the wellbore and dissipates with time. Induced radial stress shows the same trend as induced pressure. However, its peak is always at the wellbore wall. Induced hoop stress is tensile with a maximum value of about 30% of induced pressure before it decays and dissipates. Total radial stress peaks about 30% compared to base value. However, same comparison for total tangential stress shows 9% decrease due to induced tensile stress. A failure criterion can be applied to analyze the stability of the wellbore. It is noted that the time rate of surge pressure change and dynamic rock strength must be taken into account in wellbore strength management. Novel/Additive Information: The developed model presents an effective tool for wellbore stability analysis in tripping operations. A few example simulation cases are discussed. The tool can be applied for optimization of tripping operations in vertical and directional wellbores.

IADC/SPE 178825

Changing Drillstring Design to Allow Accurate Calculation of BHA Sag Corrections. S. Hinke, K. Kanji, Halliburton; B. Mracek, C. Slight, R. Happy, L. Zabcic, Brion Energy; R. Diver, Formerly of Halliburton