Digital solutions guide path to better accuracy in directional drilling

Service providers also advancing rotary steerable systems to drill more reliably in harsh environments, lower cost of operations

By Eva Vigh, Editorial Coordinator

The global directional drilling services market has taken a big hit during this downturn. In terms of market value, directional drilling fell from $16.55 billion in 2014 to $10.95 billion in 2015, then shrank further in 2016 to just $6.71 billion. Most of these reductions were brought about by project cancellations in the low oil price environment, according to Rajashekar Lokam, Research Analyst at Mordor Intelligence.

However, after three consecutive years of losses, the market appears to be reversing course. By year-end 2017, the market value of directional drilling services had risen to $9.6 billion, driven by increases in drilling activity and deepwater investments, as well as by longer lateral lengths in the US, Mr Lokam said.

No matter these market dynamics, however – or perhaps because of such market dynamics – directional drilling technologies appear to be evolving faster than ever. Operators, pinched by budget cuts, are demanding improved accuracy and quality in well placement.

“As the operator is becoming more sophisticated about completions and oil and gas extraction, they are starting to realize that, yes, it’s important to place the well quickly, but where the well is placed becomes critical, as well,” said Christopher Papouras, President of Nabors Drilling Solutions.

“They’re now realizing all wells aren’t equal in terms of their productivity, and they’re getting better at defining what makes one well better than the other, which means that placement has another layer of sophistication.”

Continuous improvement is also driving companies to develop directional drilling systems that are fully integrated with advanced software platforms, as interconnectivity and the need for optimization change the way the industry does business. Automation and digital solutions, in particular, are helping “directional drillers and MWD operators to make quicker decisions so we can execute drilling the wells more efficiently, predictably and consistently,” said Kiattisak Petpisit, Strategic Business Manager with Halliburton’s Sperry Drilling business line.

In this article, DC speaks with representatives from Nabors, Schlumberger, Halliburton and Weatherford about the latest innovations and milestones in directional drilling technologies.

Speed and quality

“Operators want to consistently drill as fast as possible with as few runs as possible and with no service quality incidents,” said Ginger Hildebrand, Operational Efficiency Manager – North America Land Drilling at Schlumberger. To deliver an industrialized performance in directional drilling, Schlumberger launched the abbl drilling operations advisor service in 2014. It leverages real-time downhole and surface data to recommend steering instructions to guide the bit along the well plan, as well as provide objective slide feedback, such as direction, length, toolface control, motor output and rotary tendencies, while steering operations are executed.

As of November 2017, the service had been used to drill more than 4.2 million ft across North American land operations, particularly in the SCOOP and STACK plays in Oklahoma, as well as the Midland, Delaware and the Western Canada basins. Over the past year, feedback from both operators and Schlumberger’s abbl command center, which monitors every well drilled using the service, has helped to improve and add functionality to the system.

While the application’s original focus was to provide real-time guidance, Ms Hildebrand said, recent developments have added analysis capabilities that allow drilling engineers to feed the results into their planning process for subsequent wells. “When things do not go as planned, operators want to understand why and how they can use the experience to do a better job for future operations.

“The abbl directional advisor is becoming increasingly sophisticated as it evolves. Initially the service possessed learned and forecasted sliding tendencies. During the next phase, rotary tendency detection was added, and later rotary tendency forecasting capabilities were included.” Other recent improvements have centered on making the service resilient against missing and intermittent data, as well as unexpected events like depth shifts.

Overall feedback from drillers, Ms Hildebrand said, has been positive. “It takes approximately an hour to fully train a directional driller, and it only takes about five minutes to set up the software for a specific well,” she said. “Users build confidence in the system with every well that they drill. Broadly speaking, we will typically introduce the abbl directional advisor as a service quality assurance tool first, and then only start crewing modifications once the operator and the crew are comfortable with it.”

The service can even be used to develop directional driller competencies and enhance performance. “The ability to closely and objectively review the night hand’s work can help avoid service quality issues and help establish a stronger collaborative relationship across shifts,” she said. “We had a case where the operator questioned a night directional driller’s ability to slide, and we used the abbl toolface control scoring to work with the directional driller to improve his skills.”

Although some directional drillers have expressed concerns about being “watched” by the software, the service was actually designed to augment the analytical skills of a good directional driller to help them consistently drill the operator’s desired well. “While the abbl drilling advisor can identify operational issues, more frequently the software highlights good operational execution,” Ms Hildebrand said. “It provides a detailed slide history illustrating the slide effectiveness to understand why some surveys are not providing the required dogleg severity (DLS) while others are.”

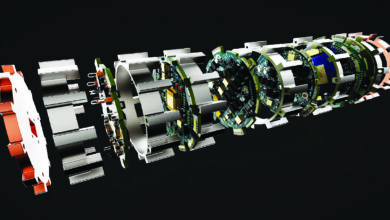

Alongside providing software that simplifies and automates workflows, Schlumberger is also developing downhole tools for harsh drilling environments; the goal is to increase reliability during directional drilling operations. In September 2017, the company launched the PowerDrive Xcel rotary steerable system (RSS), part of the PowerDrive family. The RSS is designed for use in high-profile directional drilling operations and provides a redundant inertial directional control that can be toggled with conventional control modes via downlink.

“This inertial mode is enabled by the introduction of a rate gyro on its direction and the inclination package, comprised of three-axial magnetometers and accelerometers,” said Juan Restrepo, Rotary Steerable Systems Product Champion at Schlumberger. “The PowerDrive Xcel RSS receives an accurate reference rotation in areas of high magnetic interference, allowing directional control. This mitigates collision risks of deviated holes on crowded platforms, as well as precise control in cased-hole sidetracks, ferrous formations and trajectories passing through the zone of exclusions, or where the Earth’s magnetic field projection on the cross-section of tool is low.”

The new RSS is also enabled for configuration so that it can be used as a tailor-made tool rather than one-size-fits-all, Mr Restrepo said. “The tool can be configured to maximize the curvature delivery in dogleg severity assurance applications or provide tighter control in long tangent sections. In other words, the optimal tool configuration is selected to match the directional needs, allowing both higher dogleg severities and smoother well profiles.”

Petrobras used the new RSS offshore Brazil last year to drill a sidetrack from a pilot well. This required the ability to geosteer into a complex turbidite reservoir with the potential risk of exiting the reservoir and to gyrosteer from a highly magnetically interfered environment. Because of the magnetic interference generated by the 9 5/8-in. casing, a regular magnetometer-based RSS would require about 15 m of spacing from the shoe.

This spacing had the potential to lead to a complete exit of the sandstone body, jeopardizing the well placement. The PowerDrive Xcel RSS’ inertial mode enabled Petrobras to sidetrack just 1 m below the casing shoe, achieve the full deviation from the pilot well after 16 m and build inclination from 82° to 85° with a dogleg severity of 5.33°/30 m, despite magnetic interference.

Enabling automation

Nabors has been improving upon and adding capabilities to its RigWatch Navigator software platform since the second half of 2017, based on experience gained from drilling more than 100 horizontal wells in the Bakken, Haynesville and Eagle Ford using the system. The software helps to eliminate more manual modes of conveying geosteering directions – such as phone calls or online messaging – by seamlessly incorporating geosteering decisions into the directional drilling workflow. Through Navigator, drillers receive automated directional drilling decisions and guidance every 90 ft.

“The logic in the software is maturing,” Mr Papouras said. “It is now taking into consideration multiple pieces of information, such as inclination, rotational trends and azimuth, as well as historical data from existing wells, to determine the optimal instruction to give to the human operator in order to achieve the planned well path.” For instance, if a change in drift has occurred at a certain depth in previous wells, the system will recognize a drift change is likely to occur as it approaches that depth again in a future well, and will modify its instructions.

“The system uses historical performance on previous stands to inform how you think you’re going to perform next and modify your assumptions accordingly,” he continued. “What we’ve been doing with Navigator is getting more effective historical information to inform what the instructions are going to be.”

Nabors has also extended the technology to link multiple parties within the geosteering workflow. For instance, any changes to the target are input directly into the system, and Navigator automatically updates the plan, which then becomes immediately available to any personnel involved in the geosteering process, Mr Papouras said. “It drives all these workflows into one system.”

Building on the company’s experience in drilling automation, Nabors has also developed the ROCKIT Pilot drilling software, which is expected to launch commercially in Q3 this year. It uses downhole data to rotate the top drive quill position to automatically steer the bottomhole assembly and control sliding while directional drilling. It also takes instructions recommended by Navigator to automate the entire process of executing a slide.

“Navigator incorporates best-in-class practices of prepping toolface orientation, automatic driller usage and maintaining of the toolface,” Mr Papouras said. “Ultimately, this automation capability will enable Nabors to utilize the talent of expert directional drillers on higher-value activities than the execution of slides.”

Results on eight wells drilled in the Permian Basin from June to November 2017 show that the Navigator-Pilot combination performs as well or better than human directional drillers when evaluated against decision-making and execution KPIs, he said. “For instance, on the execution side, we measured things like ROP, toolface control, pre-slide time and burn footage, all of which saw improvements from historical offsets.” On the decision-making side, one measurable KPI was number of slides for a given section of the hole compared with a human directional driller. These were found to be similar.

Both ROCKIT Pilot and Navigator were designed to integrate with Nabor’s Rigtelligent drilling control system, which has been installed on a majority of the company’s rig fleet. By leveraging a common platform across the fleet, Mr Papouras said, it will be easier to integrate new hardware and enhancements onto rigs.

A complete package

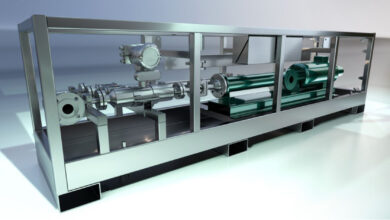

Halliburton Sperry Drilling is preparing to launch the company’s first push-the-bit RSS in Q3 2018. To accelerate the development of this new technology, the company has mobilized its own drilling rig to fast-track the testing process without impacting operators’ wells. The new RSS is designed to be rugged, with a focus on improving capabilities on weight on bit, torque and RPM to work in areas where customers are driving for higher performance in tougher drilling environments – in unconventionals, deepwater and mature fields.

The system also features advanced diagnostic and prognostic predictability for preventive maintenance and improved reliability. “This is where the machine learning comes in and where the tool can learn to predict how long it can last when it’s experiencing this type of vibration, at this frequency, at this magnitude,” Mr Petpisit said.

However, the real differentiator is its intelligent and autonomous decision-making capability, focused on driving drilling efficiency and predictable well performance, he added. The functionality is provided by the drilling advisory system, powered by downhole data and integrated into the company’s drilling automation platform. “We’re going through a digital transformation,” Mr Petpisit said. “We’re building an enterprise architecture, and part of the architecture is the drilling automation platform designed to help operators reduce well time.” The new RSS uses advanced physics-based algorithms to calculate wellbore placement up to 1,000 ft ahead of the bit.

As of March 2018, the drilling advisory software that will drive the automation system has been used to drill eight onshore wells in Texas. In these wells, the software has consistently delivered wellbore placements of no more than 3 ft away from the planned target, according to Halliburton. The new RSS also provides better management of vibrations, which Mr Petpisit called “the enemy of drilling efficiency.” Sensors on the tool collect 1,000 data sets every second – such as, vibration and rotation measurements – which are processed in the tool at a high frequency and then placed into a global database for real-time decision making. “Tool failures modes can be correlated back to type, frequency and magnitudes of vibration,” he explained. “Understanding, identifying and mitigating these vibrations can reduce downhole tool failures.”

Sperry Drilling is working with Baroid, Halliburton’s fluid services business, on the BaraLogix autonomous drilling fluid measuring system and Halliburton Drill Bits and Services, Halliburton’s drill bit division, which are developing an intelligent bit that Mr Petpisit believes can improve RSS performance and wellbore quality. “We’re working together to deliver a solution where the driller can monitor hole cleaning, pressure management, directional control and vibration management all at the same time, while helping our customers maximize asset value through more barrels and lower costs.”

Customer-driven solutions

Amidst the industrywide downturn, service companies are striving to deliver both efficient and affordable directional drilling solutions, with most customers cash-strapped and hesitant to invest in bells and whistles. “To be able to play in the broader market, you need to have an offering that is very attractive to operators in terms of being economical to operate,” said John Clegg, Director of RD&E for Weatherford’s Drilling and Evaluation segment. “We are now in an environment of much lower oil prices, and that drives the whole market to look for more budget-friendly, simple, reliable, lower-cost-to-operate tools.”

In response to this market need, Weatherford is gearing up to deliver a new-generation RSS that can be economical to deploy at $50/bbl. First commercial trials are expected in 2018. The design incorporates features such as variable wellbore direction control, which enables drilling of curve and lateral sections with the same tool while minimizing tortuosity and the risk of stuck pipe.

Customers, Mr Clegg said, are now demanding high-performance tools that enable drilling of longer laterals – in some cases, up to 20,000 ft – and address other wellbore challenges, including narrow pressure windows. The new RSS has a large junk slot area and a minimal number of contact points with the formation, which also reduces the chances of stuck pipe, he said. Further, the tool is designed to be compatible with any drill bit on the market.

The RSS is also built so that everything on the outside of the tool rotates with the bit, thus eliminating non-rotating sleeves or other non-rotating elements, “which can be a source of trouble,” he said. “Also, it’s designed so that there is no full gauge element in either stabilization or in terms of the steering head itself anywhere on the tool. Everything on the tools is smaller than the nominal hole size.”

Although Weatherford’s RSS follows the same design principles of other push-the-bit tools on the market, the key differentiator lies in its much greater variable control of the wellbore direction. “It adds a lot more refinement in terms of proportional control, allowing any trajectory to be drilled accurately,” Mr Clegg said. The control system is designed to work at any inclination and to enable vertical or horizontal drilling with the same tool.

Weatherford began designing this RSS in 2016, with preliminary testing conducted in early 2017 in the US. The company expects to run commercial trials with a national oil company in the Middle East this year. DC

RigWatch and ROCKIT Pilot are trademarks of Nabors. PowerDrive Xcel and abbl are marks of Schlumberger. BaraLogix is a registered trademark of Halliburton.