Unity launches a new range of compact well integrity technologies

Aberdeen-headquartered Unity has launched a new range of compact technologies to solve common industry challenges, including working space, component weight and personnel on board (POB) restrictions. The technologies will be used to support Unity’s surface well integrity, shallow intervention and well decommissioning services.

For offshore operations, the new products reduce well bay space requirements, simplify and accelerate offline mobilization and reduce POB, cost and risk. Due to these efficiencies, the products all offer between 50-75% savings in OPEX.

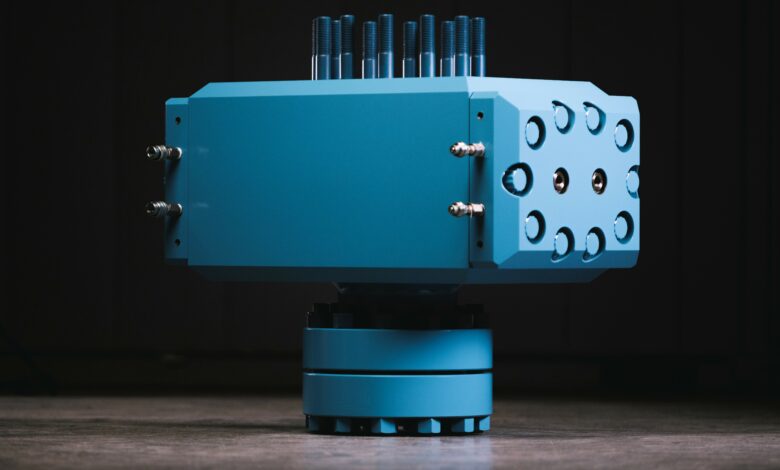

The new technology range includes a compact dual-bore Christmas tree isolation system, a compact valve removal tool and a compact shear-seal valve. The products complement Unity’s existing Surface Intervention System (SIS), the first product in this compact technology range. SIS already delivers multi-functional operations, such as inspection, plug setting, milling and Christmas tree removal, at reduced cost and improved efficiency compared to wireline or coiled tubing intervention. The SIS has a small footprint of around 2 sq ft, requiring only two technicians to operate.

The dual-bore Christmas tree isolation system has a footprint of 1.5 sq ft, with an operating height of only 6 ft above the well cap. It can be mobilized and deployed rapidly for shallow plug setting, particularly suited to support and reduce the cost of P&A operations. It can be deployed offline without the need for traditional intervention equipment. Time savings from rig-up to rig-down are in the order of 2-3 hours compared with 2-3 days for wireline or coiled-tubing interventions.

The valve removal tool is also designed for use in cramped well bays and delivers 1,200 ft/lbs torque with optional hydraulic operation without the associated space normally required for such operations.

The compact shear-seal valve is designed to reduce the weight and geometry of intervention pressure control equipment. It utilizes a hydraulically actuated ram but is 50% lighter and 30% smaller than the next closest comparable product. It is rated to cut slickline, wireline, SIS rods and coiled tubing. It is also modular in design, allowing dual redundant stack-up configurations.

“Unity is engaged in long-term contract work on over 1,000 wells around Europe, the Middle East and Africa,” CEO Gary Smart said. “Our investment in this new compact technology range has followed on the back of significant contract wins over the last 18 months, which have highlighted several common technical challenges faced by the industry, particularly in the late-life, P&A and well decommissioning market.”