Solids control seeks balance of size, capacity

High-volume centrifuges, separators, shakers keep pace with faster onshore drilling

By Katie Mazerov, Contributing Editor

The technologies that are taking hydrocarbon recovery into new frontiers are rippling through the industry, surface to downhole. When it comes to solids control, effects are being felt from faster, more efficient rigs; intense, pad drilling campaigns; improved fluid designs; and dual-gradient drilling. Companies are pushing development of higher-capacity shakers, bigger centrifuges, better screen designs and streamlined processes.

The impact is especially evident in North America’s unconventional plays. “As drilling becomes more efficient and rigs move from one pad to the next, operators are paying close attention to every aspect of the process,” said Federico Mezzatesta, Director of Product Line Management, Fluid Control, for National Oilwell Varco (NOV). “Wells are being drilled twice as fast as they were five years ago, yet generating the same amount of solids. How we deal with the solids and cuttings after they are produced is important.”

A growing trend on land is the use of high-volume, or “big bowl,” centrifuges that can remove 2-8 tons of solids

per hour from the drilling fluid and process more volume, he noted. Onshore rigs often are equipped with two centrifuges, a configuration long used in the offshore sector. For weighted fluids, the units work in a series, with the first one processing the barite, a weighting agent, and the second unit removing the low-density solids. With unweighted fluid, the units work in parallel to remove the solids.

“Solids control equipment has been efficient for many years, but we are continually looking at ways we can improve the technology, with higher-performance screens and shakers and equipment that is more compact  yet offers the same processing capacity,” Mr Mezzatesta said. “In the North American land market, where rigs are moving every two weeks and drilling times are as low as 13 days per well, we are looking at developing equipment that is more mobile, compact and easier to set up and tear down to avoid potential bottlenecks. We never want to hold up a drilling operation because of poor solids control.”

yet offers the same processing capacity,” Mr Mezzatesta said. “In the North American land market, where rigs are moving every two weeks and drilling times are as low as 13 days per well, we are looking at developing equipment that is more mobile, compact and easier to set up and tear down to avoid potential bottlenecks. We never want to hold up a drilling operation because of poor solids control.”

Centralized facilities, such as liquid mud plants, that are strategically placed to treat oil-based and water-based muds without the risk and cost of transporting waste long distances are in the pipeline. Development also advances for more efficient waste management and processing systems, such as improved mechanical and pneumatic conveyance systems and storage. “Rigs are able to drill faster, but if we can’t keep up with the cuttings collection, processing and storage, the whole drilling process will be

limited,” he pointed out. “Eventually, we hope to incorporate automation or a feedback loop into the process, making each piece of equipment as efficient as possible with the capability of communicating with each other.”

Advances in barite recovery

Keeping pace with faster drilling is a key driver in the development of Fluid Systems’ centrifugal separator for processing weighted drilling fluids. “When the industry introduced top drives, the existing equipment on rigs became limited, with many rigs able to drill faster than the equipment could handle,” noted Ben Hiltl, President of Fluid Systems. “Today, greater drilling efficiency, coupled with the development of more sophisticated drilling fluids and higher viscosities, is playing a role in pushing solids control technology to the next level.”

The company recently launched field trials for the Barkeeper, (bar signifying barite), a centrifugal separator that recovers up to 100% of the barite in weighted drilling fluids and returns it to the active mud system. The technology is expected to be fully commercialized by Q4 this year, initially targeting the North American land market. Designed primarily for oil-based muds (OBM), the system effectively replaces the dual-centrifuge design used for OBM applications.

The Barkeeper, which is used in place of the barite-recovery centrifuge, is a pumping system designed without gear boxes. It uses cyclonic technology, a high-speed rotational air flow generated within a cylindrical or conical container called a cyclone. A unit can process 250 gal/min of drilling mud, pumping fluid to a module where it is spun using centrifugal force to recover the barite slurry. Decanting centrifuges remove the low-gravity drill solids (LGS), separating out as much liquid as possible, for eventual disposal.

“Unlike centrifuges, the Barkeeper remains constant in processing the entire circulating volume of the mud system on mud weights conventionally used in shale drilling, commonly 14.5 lb, even as mud weights increase,” Mr Hiltl said. “Our experience is that the barite-recovery centrifuges rarely process more than a quarter of the circulating volume of the mud system.

“Centrifuges also are a significant capital investment, with a large bank of units required to generate energy, resulting in higher operating costs and greater environmental impact,” he continued. “Whereas a barite recovery centrifuge operates at 175 to 200 hp, we’re talking about achieving the same results with about 50 hp.” The company plans to eventually move the technology offshore with a dual-gradient, deepwater system that will separate the mud into a low-density dilution fluid and a higher-density drilling fluid.

Fluid Systems also has developed a computer-controlled shaker, with field tests expected to begin in December 2015. The shaker has a g-force of 50 to 100, compared with conventional shaker g-forces of 7 to 8, Mr Hiltl said. The Prodigy2 shaker, which can be controlled from a tablet, is being designed for the next generation of automated rigs. “The industry is searching for an automated solution, and eventually it will be a reality,” Mr Hiltl noted. The system also can be used on older rigs with simple settings.

The design uses two variable-speed motors that create linear or balanced elliptical motion at all points on the shaker basket to maximize the processing of solids and liquids. The shaker removes additional oil or diesel,

as well as oil in drilling mud, waste management and fine-screen systems. “We’re taking a shaker, coupled with software and algorithms, to sense what the rig is doing and make necessary adjustments automatically,” he said.

Adding intelligence

Alongside efficiency, safety and ease of operation also factor into solids control R&D efforts, said Michael Anderson, President and CEO of KEMTRON.

“Yes, the equipment is bigger and must perform at a higher rate with the industry’s push to be faster, quicker and cheaper, but concurrent to that natural evolution of technology is a demand for equipment that has more intelligence built into it, specifically related to the way it is operated, the experience the operator has in using it and the ability of the equipment to protect itself from fault conditions or operator misuse. Companies want to extend the life of these very expensive assets, enhance employee safety and ensure maximum uptime, especially given the continued erosion of the talent pool.”

In keeping with that focus, KEMTRON is developing a predictive maintenance sensory array that provides predictive maintenance recommendations based on continuous feedback regarding vibration, temperature, number of run hours and other parameters from sensors installed on the company’s variable frequency drive (VFD) control systems. Indicator lights alert the operator the equipment needs servicing.

The system, expected to be commercialized in Q1 2015, will provide “cruise control” capability, enabling operators to alter the performance of shakers and centrifuges to match the operating conditions, Mr Anderson explained. “Our objective is to ensure the equipment can operate for the conditions and that it doesn’t break down.”

The Hyper G Dual-Motion Multi-G Drying Shaker, introduced at the 2014 Offshore Technology Conference in May, was designed with a two-motor system that can operate in the traditional linear motion mode or balanced elliptical motion, allowing the operator to tune the g-force up and down depending on the conditions. “This provides operator flexibility to make adjustments based on the type and volume of solids coming across the shaker,” Mr Anderson explained. “The shaker can operate with high g-force for high-flow conditions but can be turned down to a less violent mode for reduced solids volume and flow, resulting in less wear and tear on the screens.” The shaker was recently deployed by an operator for 16 rigs in the Bakken and Marcellus plays.

First deployment of KEMTRON’s new big-bowl, 19-in. centrifuge came in January, with five units now operating in the US and two in Kurdistan. The company anticipates having 12 units deployed by year-end. Designed with built-in sensory logic, the centrifuge provides cruise control capability using sensory array methodology that delivers constant feedback to the control system relative to operating conditions and volume of solids.

“The sensory array feature adjusts the centrifuge’s performance relative to rotating speed, or feed, going into the centrifuge based on parameters such as torque, temperature and bearings to ensure it doesn’t operate at maximum operating stress, which can cause premature failure,” Mr Anderson said. The g-force ranges from 500 to 2,100. The unit can process LGS at 3,250 rpm to achieve a fine cut point from two to five microns, or at 1,700 rpm for barite recovery.

“The oil and gas industry is very slow to adopt new technology, but it does like to see classic technology enhanced in a way that expands the operating envelope,” he said. “We want to provide solutions that address the continued erosion of the talent pool and can be operated safely, maintain its own integrity and last as long as possible.”

Optimizing fluid performance

Solids control processing systems and modular high-performance equipment also are being enhanced to deliver value to operators by reducing mobilization/demobilization time and facilitating faster rig moves through reduced crane lifts and trucking, said Steve Williams, Marketing and Technology Manager, Environmental Solutions for M-I SWACO, a Schlumberger company.

“The goal of a solids control system is to optimize performance of the drilling fluid that becomes contaminated with LGS that need to be removed in order to minimize hole problems, reduce wear and tear on downhole equipment and maximize rates of penetration (ROP),” he said. “This is especially important in the North American land market because fluid is reused from well to well and location to location, gradually raising the level of solids contamination. The traditional way to return drilling fluids to their original specifications is to add more fluid, which requires extra trucking, storage volume and waste management.”

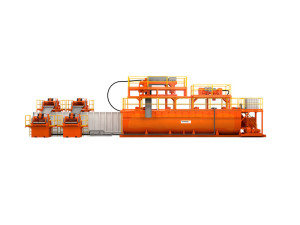

The M-I SWACO mobile closed-loop solids control system carries two big-bowl centrifuges that can be rigged up in less than two hours. It can operate in several modes: for barite recovery, for processing high-volume throughputs and for de-watering. “The closed-loop design ensures nothing goes onto the ground, helping eliminate the need for waste pits,” Mr Williams said.

On a multiple pad well project in December 2013, M-I SWACO implemented the RHE-USE non-aqueous fluid processing system to remove ultra-fine drilled solids. Using staged centrifugation with chemical enhancement, the system was able to reduce the LGS in the fluid to below the 4% target. “The savings from reducing drilling fluid dilution and minimizing waste management costs are easily quantifiable, but there is also huge added-value to the operator in the potential reduction of nonproductive time, increased ROP and therefore reduced days drilling the well,” Mr Williams said.

The Schlumberger rig engineering group works with contractors at the rig design stage to ensure the drilling fluid and solids control system is optimal and fit-for-purpose, including design of tank systems to incorporate faster automatic tank cleaning between mud system changes and rig moves. “We talk about improved efficiency from new technology implementation, but we should not forget the significant reduction in HSE risks that these innovations bring. Moving forward in this regard, we can see the industry continuing to drive for automation of the rig processes.”

The Schlumberger rig engineering group works with contractors at the rig design stage to ensure the drilling fluid and solids control system is optimal and fit-for-purpose, including design of tank systems to incorporate faster automatic tank cleaning between mud system changes and rig moves. “We talk about improved efficiency from new technology implementation, but we should not forget the significant reduction in HSE risks that these innovations bring. Moving forward in this regard, we can see the industry continuing to drive for automation of the rig processes.”

Demand also is growing globally for multideck shakers to enable higher separation performance in smaller footprints. These can accommodate faster drilling of the top-hole sections where large quantities of solids need to be processed, as well as handling the increased volume of fine solids in the lower sections of the well. M-I SWACO produces patented shaker screens with composite frames, which are up to 40% lighter than their metal-back equivalents, providing better performance as well as longer life, Mr Williams said. “The shale shaker is the first line of defense in the solids control system, and traditional single-deck shaker installations can’t always keep up with the amount and type of solids being generated and lifted to the surface. By implementing high-performance shakers fitted with our lightweight composite screens, we can help operators maximize ROP.”

On a rig in South Texas in 2013, M-I SWACO replaced the two existing shale shakers with one MD-2 dual-deck shale shaker fitted with composite screen technology in order to meet the aggressive ROP drilling target. The shaker was able to handle 100% of the flow through the top-hole section at maximum ROP. It also produced a drier solids discard and, therefore, reduced the waste haul-off costs.

Barkeeper and Prodigy2 are trademarks of Fluid Systems. RHE-USE is a mark of M-I SWACO.