Permanent production packer pushes limits of ultra-HPHT wells

Upper completion technology for as-rolled casing sets new technological boundary at 20,000 psi, 470°F

By James Doane, Guijun Deng, Scott Collins, Gary Anderson, Goang-Ding Shyu, Baker Hughes Inc

As operators continue to drill in deeper and more extreme formations, the demand for technologies to suit these environments will steadily increase. Great efforts have been made over the years to overcome the hurdles to develop safe and reliable completion tools qualified for conditions in excess of 15,000 psi and 450°F. A new technological boundary was set recently in permanent production packer development – the first 20,000-psi, 470°F permanent production packer for as-rolled casing.

A modified ISO 14310 V3 validation test was conducted on this permanent packer in as-rolled casing ID. The packer passed the test with no visible seal element extrusion, no slip damage, and there were no leaks detected at any of the load points in the test, including a bubble test.

Background

The criteria for designating fields as HPHT (Bellarby, 2009) have been changing over the years. In the past, it was fields with pressure greater than 10,000 psi and temperatures higher than 300°F (Maldonado, 2005). Currently, HPHT designation tends to be at 20,000 psi and 450°F. The term ultra-HPHT is typically used to define well environments that are above 20,000 psi and 450°F.

Design verification (analysis) and validation (testing) for HPHT packers and bridge plugs has generally been in accordance with the ISO 14310 (API 11D1) standard. Specifically for casing conditions, ISO 14310 defines that the packer or bridge plug has to be validated in the maximum ID of the rated casing or tubing sizes and weights. To meet this requirement, most of the manufacturers tested the packer and bridge plug within a machined maximum casing ID, assuming that maximum casing ID is a reasonably severe casing condition.

However, nuances of a packing element system design may result in pressure containment limits in some systems compared with others when set in an imperfect (out-of-round) casing ID. In-house tests of certain packing element designs indicated that a packer or bridge plug rated according to ISO 14310 standards functioned to higher pressure limits in maximum machined ID casing but was inconsistent in as-rolled ID casing.

In other words, the design validation and verification process of a new packing element seal system should include consideration of its ability to conform to expected irregularities since it can be more difficult for a packer or bridge plug to pass the testing in as-rolled casing than in maximum machined ID casing.

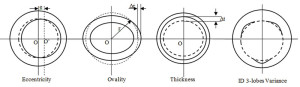

Casing ID quality is largely due to irregularities inherited from the casing manufacturing process. First, the geometric imperfection can be categorized by eccentricity, ovality, thickness variance and ID size variance (Figure 2). For as-rolled casing, geometric imperfection (Deng, 2010) could be the combination of these four defects, and the bigger ID profile variation compared with machined casing ID presents the greatest challenge.

A resilient and robust backup system for the rubber seal element has to be well designed to provide 360° support in order to prevent element extrusion. Secondly, the as-rolled production casing from operator’s stockpile can be corroded, and its ID surface is relatively rough (Figure 3). Pits, crevices and other surface defects are often visible in the ID of as-rolled casing.

Seal system design

The objective of the project was to design a packer for 6.625-in., 58.8 to 60.8 lb/ft casing. The packer was rated to pressure from below to 20,000 psi and pressure from above to 17,000 psi at 470°F. Validation testing was conducted with water to all the rating envelope points at 470°F with a cool-down to 300°F and heated back to 470°F. Customer-supplied as-rolled casing was used for testing, in addition to the maximum machined ID casing.

To enhance performance in as-rolled-casing and ultra-HPHT applications, the two concepts considered for the new seal design were:

• The Three-piece Element System, rated to 15,000 psi and 350°F. It has been qualified for applications with a groove up to 0.040 in. deep on the ID of the casing (Humphreys, 2009); and

• The Radially Expanded Element System (Doane, 2012), rated to 15,000 psi and 500°F.

The new seal design combines the best aspects of both designs. The thin metal backup profile from the Three-piece Element System was coupled with the Radially Expanded seal setting action. The combination resulted in an optimized design (Figure 4) that can be set at higher temperatures and hold higher pressures with improved performance in irregular as-rolled casing.

Slips System

Tangential slips were used to minimize the stress on the casing and packer body. Tangential slips have a large contact area with the casing, which reduces the pressure that the slips apply to the casing. Also, the design of the tangential slip system prevents collapse loads from being applied to the packer body. This design causes the slips to apply a tangential load to the slip seat instead of radial load, which keeps the load off

the packer body. A double-grip slip system design will ensure that the seal system movement will be minimal under both tension and compression loads, and therefore the risk of damaging the seal system on as-rolled

casing will be decreased.

Other accessories

The packer was designed to minimize the burst pressure on the casing and the collapse pressure on the packer body. A body lock ring between the slips and swage prevents the swage from applying force to the seal with pressure differential above the packer. The pressure above acts on the area from the seal ID to the swage ID to create an axial force on the swage. If there was no body lock ring, this axial force would be applied to the seal, which would apply a radial force on the casing. This radial force would be very high due to the shallow angle on the swage. Instead, the axial force is restrained by the body lock ring.

Material selection and characterization

Perfluoroelastomer (FFKM) was chosen as the rubber material because of its temperature and chemical resistance. FFKM has the highest temperature rating (greater than 450°F) and best chemical resistance of any known elastomer. Since the application for this seal is for the harshest well environments, FFKM is the optimal choice. The compound chosen is stable in oil, amines, H2S, CO2 and zinc bromide. In addition, the compound is stable up to 500°F and is NORSOK-qualified for explosive decompression.

Nickel alloy C-276 was chosen as the material for the seal carrier because of its excellent ductility, corrosion and cracking resistance. The material properties of C-276 at various temperatures, such as room temperature, 250°F and 500°F, have been determined because they are critical data for design optimization

Design verification and optimization

To reduce development cost and time, finite element analysis was heavily used for design verification and optimization in the development of the ultra HPHT packer seal in as–rolled casing (Figure 5).

To be considered as a viable design, the following criteria must both be met:

1. The equivalent plastic strain in the metal should not exceed the maximum allowable plastic strain, and the maximum elastic strain in the seal should not exceed the maximum allowable strain; and

2. The seal must be able to set and withstand 20,000 psi above and 17,000 psi below without packing element extrusion.

The process was repeated until an optimum seal design was achieved, and then a 3-D FEA model was set up to identify the minimum setting force. The 2-D FEA model assumed the casing ID was perfectly round, and the 3-D FEA model took into consideration the as-rolled-casing ID profile with as much as 0.050-in ID variance.

Test validation

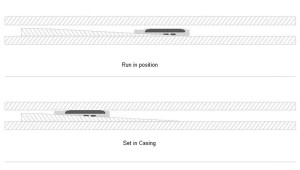

This new production packer (Figure 6) was installed in a test cell with customer- supplied as-rolled casing. The ID profile varied 0.050 in. The variation was due to eccentricity and lobes. The variation due to eccentricity was 0.020 in., and the variation due to the lobes was 0.030 in. The validation testing was conducted with water to all the rating envelope points at 470°F with a cool-down to 300°F.

Test objective

The objective was to determine if the packer could hold pressure at 20,000 psi at the maximum temperature of 470°F and the minimum temperature of 300°F.

Test load cases

The following seven load cases were tested using water as the medium:

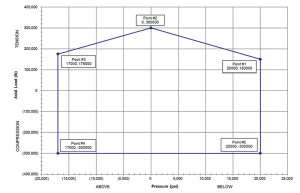

I. Rating envelope point #1 (20,000 psi pressure below with 150,000-lb tension at 470°F);

II. Rating envelope point #2 (300,000 lbs of tension at 470°F);

III. Rating envelope point #3 (17,000 psi pressure above with 175,000-lb tension at 470°F);

IV. Rating envelope point #4 (17,000 psi pressure above with 300,000-lb compression at 470°F) and temperature cycle (470°F-300°F-470°F); and

V. Rating envelope point #5 (20,000 psi pressure below with 300,000-lb compression at 470°.

In addition to the testing outlined above, a nitrogen test was conducted on load case I and V.

Test results

A performance envelope was plotted (Figure 7) based on the test results of the five load cases.

At the end of the test, the test fixture was disassembled. The casing was cut open to remove the packer. Figure 8 shows the tested seal unit after the test. No visual element extrusion was identified on the seal element and seal insert.

Figure 9 shows the packer slip system after the test. There was no damage to any of the packer slip components after the test.

Conclusions

A major milestone in upper completion technology has been achieved. For the first time, a permanent production packer was successfully built to seal a pressure of 17,000 psi from above and 20,000 psi below at both 300°F and 470°F in as-rolled casing.

This article is based on a presentation at the 2013 International Petroleum Technology Conference, 26-28 March, Beijing.

References

Bellarby, J., Well Completion Design. 2009, 1st edition, Elsevier, Amsterdam, p. 639-641.

Deng, G., Shyu, G, “An Innovative Approach to Optimizing Design of HP/HT Well Tubular Strings,” SPE 132550, 2010 SPE ATCE, Florence, Italy, 19-22 September 2010.

Doane, J., Deng, G., Collins, S., “A Completion Technology Milestone – The First 25,000-psi 500°F Packer Seal System,” SPE 159182, 2012 SPE ATCE, San Antonio, 8-10 October 2012.

ISO 14310: 2008, Petroleum and Natural Gas Industries – Downhole Equipment-Packer and Bridge Plug.

Maldonado, B, September/October 2005, “Special Design Strategies Vital as HPHT Completion Edge Towards 500°F, 30,000 psi.” Drilling Contractor, Proc. SPE/IADC Drilling Technology Conference, Aberdeen.

Humphreys, A., Ross, R, “Delivering a Fully Qualified HP/HT Production Packer Following Field Failure,” March 2009 SPE Drilling & Completion.

Shyu, G, “Review of the Application of FEA to the Development of WL and Premier Packer,” MSC Software 2007 Virtual Product Development Conference.