Performance, engineering for safety and environmental impact among top considerations for next newbuilds

KCA Deutag’s Simon Drew: Rig availability may soon be challenged in some markets, but improved ROI will be needed to incentivize fleet additions

By Linda Hsieh, Editor & Publisher

Simon Drew is President of Land Drilling for KCA Deutag.

What do you see as the most critical challenges as you look across your fleet of 70-plus land rigs?

Over the past few years, we have been especially focused on enhancing our brand by adding value for, and reducing the total well cost of, the customer. The challenge is how to do that in a downturn, where so much focus is on pricing.

But with that said, I think we have made progress in overcoming this challenge. We do see interest in technologies and a willingness to invest in things that can deliver value. And it’s really up to the drilling contractor to figure out how to demonstrate enough value to the customer and to show them that the overall well cost can be lower, even if some investment is required to achieve this.

The second challenge is how to generate a return from investments that were made in our fleets when the market was healthier. Obviously, there’s been quite a bit of excess capacity over the past few years, but I think this challenge will be resolved over the next few months – especially in the Middle East and Russia, which are KCA Deutag’s core operating areas.

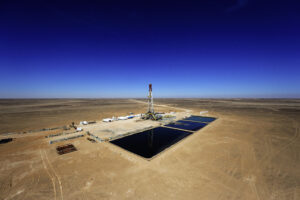

In those areas, we’re seeing growing demand for land rigs, particularly for the heavier end of the market, such as 1,500- to 2,000-hp or even 3,000-hp rigs.

Looking further down the road, I believe rig availability will become a challenge as operators look to grow their contracted rig fleet and as excess capacity disappears. But for drilling contractors, we will have to see a sufficient increase in the return on investment before we can allow more investments into land fleets.

To that end, we are seeing some customers starting to look again at long-term contracts and other models to allow investment in the growth of the fleet, and we are proactively working with our customers in many areas to explore how we can collaborate to achieve this.

You gave a keynote address at the IADC Advanced Rig Technology Conference a few months ago where you said that the rig revolution was ahead of its time. Can you elaborate on that?

I meant that the talk of a rig revolution ran a little ahead of the reality on the ground. KCA Deutag, like others in the industry, proved that having a highly automated rig was possible. The example I gave was our Euromatic 2,000-hp T700 rig, which is very heavily mechanized and can run pipe without anyone on the rig floor.

But there were still blockers to such technology at the time. That, coupled with the industry downturn, meant the widespread adoption of new automated rigs has been slow. However, my point was that the industry can realize significant benefits from technology by enhancing our existing fleet instead of building a whole new set of highly robotic machines of the future.

Over the coming few years, I do think that the industry will ramp up the building of rigs, but those will be incrementally more mechanized versions of existing rigs rather than revolutionary automated new designs.

What is KCA Deutag doing to adopt more digital/automation technologies, and what challenges have you encountered?

In 2019, we launched a marketing campaign called the Well of Innovation, and we have a suite of technologies under what we call +veDRILL, which we believe can bring significant value to our customers.

In terms of the challenges of navigating the new technological landscape, I would describe it as, we have lots of potential hammers, but we need to find the right nail. This means, how do we pick from the plethora of tools that are out there and find those that can truly add value to the processes in our specific industry?

The answer to that challenge is to proactively collaborate with our customers. With our focus on customer centricity, we are listening to our customers to understand their needs so that we can continue to invent solutions.

Can you give an example of what you’re doing with AI or machine learning?

Sure. If you look at all the in-house data we collect, that includes both numbers and text descriptions of various operations on our daily drilling reports. And we’ve been collecting that data from about 70 rigs for 15 years. We’re now exploring deployment of AI and natural language processing to go through comments from 15 years of daily drilling reports and find trends, as well as cause and effect issues.

For example, it could tell us that perhaps nine times out of 10 before you experienced stuck pipe, you saw similar descriptions or similar issues in those drilling reports. That can point to places where we need better training or identify opportunities for using automated systems on the rig to avoid stuck pipe.

We’re still exploring how this would work, so this is still early in development.

What are the barriers to leveraging more of the data generated on rigs today, and how can those barriers be addressed?

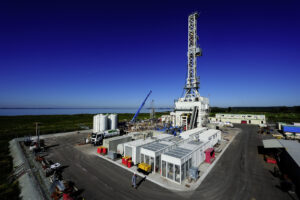

Because we often work in very remote environments, data accessibility can be a big challenge. We’ve spent quite a lot of time and effort to develop and implement a system called FX-Control to get that data off the rig. This is not just for our own data, but we have the capability of acting as a conduit for other people’s data. In addition, the system allows for control signals to be sent back to the rig, so it creates a closed-loop process.

We have trialed this system in Oman, with data being fed off the rig to a computer and that computer running the data through a drilling optimization algorithm. It then sends signals back to the rig telling it how to drill the hole section.

So the computer will drill the stand down in what is basically an automated process, and the driller will watch the process, with his hand over the stop button in case he needs to intervene.

Two other barriers I see are visibility and how we turn data into knowledge and decisions. For this, we now have our Insight tool, which helps us to structure the data we have in order to find trends and cause and effect, as I mentioned earlier.

You also mentioned that you may be building more rigs in the next year or two in order to meet operators’ needs. What will be your main considerations for these newbuilds?

Clearly, performance will be key, and how to reduce overall well cost for the customers. As I mentioned, we’re in a situation where companies will have to look at long-term commitments in order to bring new rigs into the fleet. That’s going to enable positive conversations about what these new rigs are going to be used for and how best to set them up for performance and reducing well cost.

Secondly, engineering for safety will be critical. One example is how Bentec has built anti-collision systems into the bail arms of its top drive, which prevents collisions with the monkeyboard. That’s a feature that wasn’t on the previous generation of top drive. Another example is having BOP interlocks so that the drawworks can’t move if the ram BOP is closed.

Lastly, we are seeing more and more environmental concerns. I look back at our Euro rigs that were built 10 or 15 years ago. They had low noise emissions and height restrictions. They were designed to run off the grid, and they had much better containment for spillages around the site. I hope that we’re going to see more of these features coming into rig design in general.

We’re also looking at having hybrid rigs using battery power. I know there’s already some of those offshore, but we’re looking at the same thing for land.

Do you see any moves to increase equipment capacities? Are we going to see even bigger rigs in the future?

So far, what we’ve seen are incremental enhancements within each size of rig, rather than a fundamental shift in the size of rigs. For example, enhancing top drives to provide 5% or 10% more torque with each evolution. We may also start to see people interested in 7,500-psi fluid-pumping pressures instead of 5,000, as they have already seen in the US.

What are your thoughts on potential changes to drilling contractors’ business models?

I think that, regardless of what model we use, we have to demonstrate value. Sometimes people talk about either dayrate or turnkey, but there’s a whole spectrum of opportunity between those two bookends, within which we can share the risks and the prize.

You’ve probably heard of the incentive model, which has been working for us quite well. We see a lot of our customers are measuring both macro KPIs around well times and HSE and then micro KPIs around tripping speeds and BOP handling times. Some of our customers are very willing to work within this incentive model, and we would like to do as much of it as we can, too.

How do you make the incentive model sustainable in the long term?

That’s always a challenge, but ultimately we have to demonstrate that we can keep improving. Generally, if you’re continuing to deliver value to a customer, I think they will pay for it, because the principle is that you’re sharing the prize.

I want to end by asking about safety. Have we plateaued? What more can we do?

My belief is absolutely not. Zero TRIR is possible, and we are seeing a number of our countries achieve it. For example, we have 24 rigs in Oman, and they have gone two and a half years without a recordable incident. This isn’t to say we don’t have challenges, but we continue to “drive to zero,” as we call it at KCA Deutag.

What tends to happen is a company will see big improvements for a while, then it steadies out or even dips, and then more energy is applied and you’ll see big improvements again. I believe that the next improvement cycle can bring us very close to zero TRIR across the fleet.

We’ve now moved on to also look at total hurt as the next smallest measure of safety to manage. This goes down to first-aid cases, bruises and scratches. So, no, I don’t think we’re plateauing.

Going forward, we need to focus on three areas. First, stick to what works. This means ensure compliance to the safety systems we’ve already developed over the years that have proven effective.

Second, innovate what needs to change and where we see weakness. That innovation needs to come from the bottom up, i.e. from the whole crew, as well as from the office.

Third, we need to continually work on team behaviors and leadership. On any successful rig, there’s always three or four great leaders at the heart of the rig, and the crews will respond to those leaders. DC