No room for failure in RSS performance as cost pressures persist

Industry looks to rig integration, real-time monitoring, autosteering to help rotary steerable systems drill faster, last longer

By Kelli Ainsworth, Associate Editor

- Integration of rotary steerable systems with a drilling rig’s systems and software can enable new workflows and reduce costs.

- Recognizing that mechanical changes alone can’t improve vibration management, RSS tools are being paired with real-time modeling and monitoring to identify deviations from optimum performance.

- Further cost reductions are being sought by ruggedizing tools for improved durability and by eliminating non-essential sensors.

Today’s rotary steerable systems (RSS) are being developed with one primary goal: delivering high-quality wellbores at low cost. Some service companies are reducing costs by developing more durable tools that can drill for longer in harsh environments, while others are focused on reducing the cost of the tool itself by eliminating non-essential functions. At the same time, service companies are also looking to leverage real-time monitoring and data analytics to deliver the highest ROPs possible without inducing damaging vibrations. Drilling contractors, too, are developing RSS technologies that can integrate with their own rig equipment, software and controls.

Whatever approach a company takes to lower the costs associated with using an RSS, they’re all trying to deliver a high ROP with little downtime. “Our customers wanted to push harder. They’re under economic pressures to get a bigger return on their investment, so they want to spend less on their wells, which requires getting the wells done quicker with fewer failures,” said Paul Bond, Product Manager for Halliburton. “I think there’s pressure on the RSS providers to provide equipment and services that can drill faster, hit the targets and not fail. That’s where we have been since the downturn. It’s all about delivering the best value.”

As laterals become longer, RSS technologies must not only enable faster drilling but also endure extended runs, said Paul Neil, Director of Steerable Technologies for National Oilwell Varco (NOV). “We need to be able to develop the technologies so that they are durable, reliable and can handle the length of the run, while delivering a high-quality borehole.”

In this article, Drilling Contractor speaks with experts from Nabors Drilling Solutions, NOV, Halliburton, Schlumberger and Baker Hughes about their latest innovations and achievements in RSS technologies.

Integration for better workflows

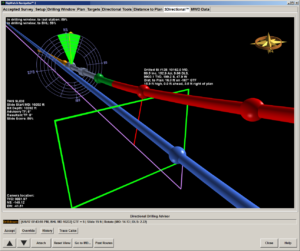

The ability to integrate rotary steerable systems with a drilling rig’s systems and software enables new workflows and lower-cost wellbores, Joey Husband, Vice President of Global Operations for Nabors, said. In an expansion of its wellbore placement offerings, the company will soon introduce a new rotary steerable system. The system can be used on third-party rigs or paired with the company’s “Directional-Ready” rigs, which include integrated equipment and instrumentation to enable high-fidelity surveying and accurate placement into productive targets of long-reach lateral wellbores.

“We believe that by having Directional-Ready rigs featuring specially trained drillers, drilling performance software, and reliable MWD telemetry combined with our new RSS design, we will be able to deliver a game-changing value proposition for rotary steerable technology,” Mr Husband said.

Nabors has already used the new RSS to drill test wells in Norway and is now in the process of testing the new RSS on one of its rigs in Catoosa, Okla. The RSS, with a build rate of 15°/100 ft, has been under development since 2014. Rather than a push- or point-the-bit steering mechanism, it features continuous orientation control. The tool has near-bit inclination, directional sensors and a downhole closed-loop control mode. The near-bit sensors provide direct feedback to ensure appropriate positioning of the continuous orientation unit to stay on course. “We’re drilling a smooth wellbore because the measurements are close to the bit, so we see them quickly,” he said. “The tool automatically adjusts itself to ensure accurate steering at high penetration rates.”

To reduce wear and maintenance on the tool, Nabors designed the RSS without external moving pads. It’s also powered by a turbine, rather than batteries, to prevent having to pull the tool for battery replacements. “The basis for design was for a low capital investment and low maintenance cost but also the ease of use on our rigs, which would enable, for example, our drillers to pick up and run the tool without bringing any additional people onsite,” Mr Husband said.

The tool arrives at the wellsite preprogrammed and already designed to consolidate with the company’s proprietary instrumentation, equipment condition monitoring and data acquisition software, so it can be run by the driller with minimum onsite support.

Nabors has also developed software solutions to optimize rotary steerable performance. The company’s REVit system can be used with any rotary steerable technology to help reduce stick-slip while drilling. The system mitigates damaging drill string harmonics that occur under certain drilling conditions that can result in lower penetration rates and unplanned trips due to MWD and bit damage. “Upon sensing an abnormal harmonic from the drill string in the top drive accelerometers, our control software counteracts and destroys the vibration with quill movement control while drilling, thus attenuating high torque cycles seen in the string under certain conditions of rotational speed and weight on bit,” Mr Husband said. Preventing stick-slip can extend bit life and reduce nonproductive time.

Through Nabors’ RigWatch system, the contractor is able to monitor RSS operations from its RigLine 24/7 remote operations center in Houston. “A single directional driller at a remote operations center can oversee four to five rigs at a time, providing additional expertise to the directional drillers at the wellsite,” Mr Husband said. “We’re able to take a great directional driller and put them in a central location to monitor and to assist in drilling multiple wells at the same time versus having that particular expertise committed to one rig.

“Having highly experienced directional drillers oversee multiple rigs remotely helps the contractor scale up activity,” Mr Husband continued. “Our ability to take capable and experienced people and have them manage multiple rigs will mitigate the impact of the normal staffing constraints during an upcycle that we’ve seen in the past.”

No-frills options

While sensors on the RSS tool can provide data needed to guide a directional drilling operation, they also represent added costs. When drilling well-understood onshore fields, operators may not need such additional features while drilling lateral sections. Recognizing this opportunity for cost reduction, NOV is developing a fit-for-purpose RSS for drilling lateral sections in unconventional wells, the VectorEDGE system, which eliminates near-bit sensors and built-in MWD equipment to cut the cost of the RSS in half.

“We wanted to strip out all the bells and whistles that weren’t mission-critical to drill these lateral sections to keep the cost down,” Mr Neil said. The push-the-bit VectorEDGE system is currently available in the 6 ½-in. size, enabling applications in holes from 7 7/8 to 8 ¾ in.

NOV designed this RSS to require minimal interaction at the drill site. The tool has a closed-loop trajectory feature so that it can autonomously adjust its aggressiveness to align with the directional plan based on data from sensors. “It’s autonomous in the sense that you don’t always have to continuously send steering instructions, known as downlinks, to the tool to steer it,” Mr Neil said. Revisions to the well plan or a geological change in the formation may still require downlinks to be sent, however.

When downlinks are sent, it’s done via pipe rotation, which is considered to be more reliable than using mud hydraulics, he explained, adding that downlinking for the VectorEDGE system has been tested to 27,000 ft. The directional driller inputs the desired toolface and aggressiveness into the software, which notifies the directional driller how to change the pipe RPM to send a new steering instruction.

Although the tool does not have an MWD system built in, NOV designed it to be compatible with any mud-pulse or electromagnetic telemetry MWD system, should the operator or directional company want to utilize one. It can also be attached to a motor, should the operator wish to increase RPM to deliver higher ROP.

NOV began designing the VectorEDGE system in 2012. Preliminary testing, including some performed on NOV’s test rig in Navasota, Texas, took place in 2014 and 2015, and dedicated field tests in West Texas and the Northeast US have been ongoing since 2016. Early results have shown that, when run with an NOV bit and motor, the tool can achieve the same or higher level of performance as other RSS tools on the market, Mr Neil said. “Because we are focusing on cost so much, if we can drill a well as fast and as accurate but at a lower cost, then it can really impact our customers’ economics.” The company is targeting full commercialization of the tool by the end of 2017.

Optimizing RSS performance

Service providers are also working to improve the vibration tolerance of their RSS systems, particularly in environments like Brazil’s pre-salt and mountainous areas like the Rockies and Andes. Vibration can be a particularly tough challenge in those environments. The latest addition to Halliburton’s GeoPilot point-the-bit RSS platform, the GeoPilot Duro, was released in November 2016 to drill in vibration-prone environments. The tool’s bearings and electronics have been ruggedized to increase its shock and vibration tolerance so that “we can push the envelope of how we can operate this tool and get higher ROP and stay in the hole,” Mr Bond said. In addition, its stabilizers have been redesigned with deeper channels to increase the flow-by area by 73%, reducing cuttings accumulation around the tool for better hole cleaning.

However, such mechanical changes won’t, on their own, deliver better vibration management, Jeremy Greenwood, Chief Global Advisor for Drilling Performance, said. “You have to know what the optimum drilling parameters need to be and the various risks and challenges of drilling in that environment, zones that may produce high vibration, zones that are difficult to steer in and zones that are unstable.” To that end, the GeoPilot Duro is automatically deployed with pre-job engineering and real-time monitoring through Halliburton’s ADT Optimization service. With the addition of the ruggedized tool, upfront planning and real-time monitoring, the company is able to expand the operating window of the service. The operating RPM limit is increased to 300 RPM while the operating range for high vibration has been increased by between 33% and 100%, according to Halliburton. The new limits enable wells to be drilled faster while helping to significantly reduce potential nonproductive time.

The service monitors for vibration – particularly stick-slip and whirl vibrations – as well as hole cleaning, torque and drag. During pre-job modeling, the well plan and drilling parameters are input into the system to identify potential challenges and ways to address them. “We want to identify what our best performance could be – optimum ROP, optimum hole cleaning and most efficient trajectory construction – so that we hit the target with no corrections and little time spent adjusting the trajectory,” Mr Greenwood said.

When drilling begins, the models are updated with real-time information. If the data matches up with the model, it lets the company know they’re seeing optimum performance. “If we start to see a deviation between the real-world responses and the model, we know that something’s happening downhole that we need to respond to. We can then diagnose the cause of the difference between our measurements and the assumptions in the model and make modifications to the drilling process to optimize the performance,” he explained.

Sensors in the GeoPilot itself, including accelerometers, gyroscopes and magnetometers, indicate shock and vibration presence and severity. This data, taken in conjunction with surface data, is used to determine the particular mechanism of vibration that’s occurring and its cause, so the right corrective action can be taken, Mr Greenwood said. Knowing exactly when and how vibration occurs and with which drilling parameters allows the company to run the tool at the highest ROP possible without inducing vibration.

The GeoPilot Duro RSS service was provided for an operator in Latin America who wanted to drill a salt section in a single run. According to Halliburton, the operator had planned to drill the well in 10 days, but the GeoPilot Duro and associated services enabled it to be drilled seven days, saving the operator three days in rig time.

Power for Performance

Boosting ROP and cutting down drilling times have been major drivers for Schlumberger’s RSS development. In Q1 2017, the company commercialized the newest entry to its PowerDrive RSS portfolio, the PowerDrive vorteX Max. The high-powered system combines the high-torque and RPM capabilities integrated with advanced modeling through its IDEAS integrated dynamic design and analysis platform. “It unlocks a higher ROP and, at the same time, it optimizes the power section through advanced modeling,” Juan Restrepo, RSS Product Champion, said. “This provides a very robust system.”

The tool’s power section converts mud hydraulic power into mechanical energy, which translates into higher on-bottom ROP from the added RPM and a higher weight-on-bit capability. The company states that it is capable of increasing RPM by nearly 60% compared with a standard RSS, according to advanced modeling, prototype lab analysis performed by Schlumberger, as well as field experiences from land drilling operations.

As an add-on service, pre-job modeling with the IDEAS software allows Schlumberger to optimize the performance of the complete drive system and assess for drilling and hole conditions impacting RSS performance. The software, which was launched in 2011, runs 4D, time-based simulations that capture the entire drillstring and wellbore geometry in order to predict and optimize BHA performance and life. The software can calculate the performance of a variety of bits and RSS tools in a range of formations and rock types. “This modeling provides operators with the confidence that they can efficiently make TD,” Mr Restrepo said.

The system also has an autosteering function that holds the desired inclination and azimuth without input from the directional driller. Typically, the directional driller tracks the inclination and azimuth and sends a downlink to change the settings if it becomes necessary – for example, in the presence of an interbedded formation. This RSS is able to respond on its own to maintain the desired direction, Mr Restrepo explained. “Having the tool just decide itself represents a change in the role of the directional driller,” he said. “Instead of executing, their role can move to monitoring, to ensure the tool is doing what it’s supposed to do. That translates to higher performance and consistency because it eliminates all these commands, downlinks and interpretations.” With a complete direction and inclination package, the RSS is able to provide autosteering for both inclination and azimuth, which is a relevant automation step from the earlier inclination closed loops.

Over the past 12 months, the PowerDrive vorteX Max high-powered RSS has been used in 80 wells for Parsley Energy in the Midland and Delaware basins. Preliminary results from this 80-well campaign indicate that the operator was able to reduce the average number of drilling days by 17% compared with the previous year. The operator has also reported a 30% reduction in the average total drilling cost per lateral foot, according to Schlumberger.

Another RSS from the PowerDrive platform, the Orbit, which was commercialized in 2014, was developed for performance drilling in long runs both on land and offshore. One of the tool’s primary differentiating features is its metal-to-metal seals – evolving from the use of elastomer seals, Mr Restrepo said. “When you have metal-to-metal seals, you increase resilience,” he added.

The metal seals are able to tolerate aggressive oil-based muds and complex fluids in a way that elastomer seals cannot. They’re also able to withstand higher temperatures, whereas the performance of elastomer seals is affected by its chemical interaction with drilling fluids. “Rubber is going to be affected when you start using oil-based muds, or you’re running in high temperatures, or you’ve got high solids content,” he said. “If you remove the weakest link from the equation, then you can start pushing on higher parameters such as RPM.”

In 2016, the PowerDrive Orbit RSS was run in an 8 ½-in. hole for Laredo Petroleum in the upper Wolfcamp in the Permian. The operator had previously used conventional motor BHAs in this field, which were challenged in extended lateral wells due to drag. When Schlumberger deployed the PowerDrive Orbit, it was able to drill a 13,602-ft lateral in a single run, with an average ROP of 125 ft/hr. It drilled for a total of 108 hours.

In late 2016, the system was deployed for Eclipse Resources in the Utica. It was run with a Smith Bits PDC bit and Schlumberger’s TelePacer modular MWD platform in an 8 ½-in hole. In this run, the BHA drilled an 18,752-ft lateral in a single run, in a well with a total depth of 27,048 ft. The system achieved an average ROP of 118 ft/hour and was run for a total of 157 hours. Like the PowerDrive vortex Max, this system has autosteering capabilities. “So for most of those hours, the tool was self-steering and didn’t really require the intervention of the directional driller because the tool is holding both inclination and azimuth through these long laterals,” Mr Restrepo said. He added that the BHA remained in the geological window during the entire run.

Getting more out of each run

The shale boom in the US has driven the development of rotary steerable systems that can drill both high doglegs and long lateral sections, such as Baker Hughes’ AutoTrak Curve RSS. Since the system’s launch in 2013, it has been used in increasingly long runs, often to drill the entire vertical, curve and lateral sections of a well in a single run, Denise Azuaga Livingston, Automated Drilling Systems Global Product Manger, said. “If you can save trips and reduce the number of days it takes to drill the vertical portion of the well, or the curved section or lateral, and do that with one BHA, it’s usually the way to go.”

In early 2017, the AutoTrak Curve RSS was used to drill the vertical, curve and lateral sections of an 8 1/2-in. monobore well in a single run through the Niobrara formation in the DJ Basin in Wyoming. Using the AutoTrak RSS in the 6 ¾-in. size, along with a Baker Hughes Navi-Drill Ultra XL45 motor and an 8 ½-in. Talon Force high-velocity drill bit, the operator set a basin record by drilling 15,261 ft in 1.95 days. It also achieved a daily footage record of 8,267 ft in 24 hours.

Prior to deploying the AutoTrak RSS, the operator used conventional steerable motors, and average daily footage in the area was 3,194 ft, with an average time of 5.2 days for surface drillout to total depth.

Baker Hughes deployed a BHA consisting of its AutoTrak RSS, motor and bit and switched from a water-based mud to an oil-based mud after kickoff. The entire section was drilled to a TD of 17,857 ft in a single run, with an on-bottom ROP average of 443 ft/hr. The operator met the planned trajectory of 10°/100 ft build-up rate.

This operation set a basin spud-to-TD record time of 3.5 days. It also represents a 33% decrease in the operator’s drilling time, compared with offset wells.

A key feature that enables the system to drill long runs efficiently is its near-bit sensors, Ms Livingston said. “The near-bit inclination sensors allow the AutoTrak Curve to better predict BUR ahead of the surveys from the MWD and to precisely control TVD in the lateral section, improving wellbore quality, reducing tortuosity and minimizing torque and drag in long horizontal sections. In addition, by having vibration sensors near the bit, you can quickly identify any drilling dysfunctions close to the bit. As a result, you can proactively mitigate them and significantly improve your drilling efficiency.”

In addition, the continuous proportional steering mechanism, a cornerstone of the AutoTrak portfolio of RSS tools, works to steer the well in the desired direction, resulting in a smoother and less tortuous borehole. The RSS has three pads mounted equidistant from one another that are always working, Ms Livingston said, rather than being either on or off, as is often the case in push- or point-the-bit RSS systems.

“A lot of other systems use an on-and-off steering mechanism that is almost like a motor,” she said. “You’re steering or you’re not steering. Continuous proportional steering is always working toward your directional goal.” The continuous proportional steering mechanism doesn’t have to be run with a particular type of mud or fluid, nor does it need a specific pressure drop across the bit, nor a particular bit type to deliver its directional control, she added. DC

RigWatch, RevIt, Directional-Ready, RigLine 24/7 and SmartRig are registered terms of Nabors. VectorEDGE is a registered term of NOV. GeoPilot Duro is a registered term of Halliburton. PowerDrive Orbit, PowerDrive vorteX Max and IDEAS are registered terms of Schlumberger. AutoTrak Curve is a registered term of Baker Hughes.

- Nabors is developing a rotary steerable system that will be key to the transformation of its fleet of 100 SmartRigs into what the company calls Directional-Ready rigs.

- Pipe rotation downlinking for NOV’s VectorEDGE system has been tested to 27,000 ft.

- The flow-by area in Halliburton’s GeoPilot Duro has been increased by 73%, reducing cuttings accumulation around the tool for better hole cleaning.

- For an operation in the Utica in 2016, Schlumberger’s PowerDrive Orbit achieved an average ROP of 118 ft/hour and was run for a total of 157 hours.