KCA Deutag deploys artificial intelligence to extract lost-time insights from daily drilling reports

Analysis of massive amounts of unstructured comments provides continuous opportunities to help operators identify root causes of NPT, invisible lost time

By Jessica Whiteside, Contributor

KCA Deutag is on a mission to make drilling operations more efficient and cost-effective through the application of artificial intelligence (AI) technologies. The company’s latest machine learning tool uses natural language processing to enable bulk analysis of text-based drilling reports to illuminate systemic causes of costly lost time.

Now implemented on over 91% of the KCA Deutag-operated rig fleet, the machine learning model uses a sophisticated algorithm to assess textual comments submitted to the company’s existing enhanced drilling reporting system (EDRS). Usually, the unstructured nature of such written comments would make them difficult to analyze. However, the algorithm automatically classifies each entry as either a rig problem, a well problem, normal operation, HSE event or waiting time. This categorization allows the company’s performance teams to more easily analyze large volumes of drilling reports to help identify recurring lost-time trends. The tool is especially helpful in pinpointing invisible lost time, or inefficient practices that can hamper well progress even without complete downtime.

KCA Deutag initiated the project in February 2020 in collaboration with AI specialist Endila, which provided the data science expertise, and the UK-based Oil and Gas Technology Centre, which contributed funding. The goal was to help customers, some of whom were experiencing 20-40% overall NPT per well, said technology engineer Anna Moffat, who managed the project.

“We wanted to see how we could help,” she said. “We didn’t want to reinvent the wheel, so we looked at what we already had.”

What it had were 4 million rows of unanalyzed free-text data from its internal EDRS database. Drillers on every KCA Deutag-operated rig enter information about drilling activity into this system. While most data can be entered via drop-down menus, individuals can also enter text, describing rig activities in their own words (e.g., “Drill from 34 to 64 m”). After initial submission and review, these comments are typically never viewed again, unless required as part of an operational investigation.

The KCA Deutag performance teams believed that an analysis of these unstructured comments could reveal important insights into the root causes of customer NPT and ILT. However, unlike the structured data from the drop-down menus, which could be bulk analyzed, there was no effective way to dissect and analyze these free-text entries on a macro scale.

Not only was the volume of text huge – and growing with new entries every day – but the comments also contained a lot of “noise,” such as inconsistent abbreviations, spelling errors, punctuation and special characters. An AI approach was needed that could remove this noise and put the comments in a format that would support complex data analytics.

Developing the machine learning model

For this project, Endila developed an algorithm to process the natural language of the drillers’ written comments and predict their categorization based on the words used, frequency and association with other words. For example, the word “investigate” is often associated with a maintenance or safety issue.

The model doesn’t read words as a human would; rather, key words are reframed as numbers that can be processed using vector formulas. Classification predictions are developed using statistics, without needing to understand the meaning of the comments, i.e., without any human intervention.

The developed process included:

• Extracting 4 million rows of raw data from the EDRS, which was reduced to 3.1 million rows after formatting and ensuring each row would represent a single drilling report entry;

• Running these entries through a data-cleansing algorithm to remove noise;

• Manually tagging 40,000 rows of this clean data with one of the five classification labels to create a data training set;

• Training the model on the words commonly found in each classification category (the system now contains most of the industry’s drilling vocabulary); and

• Running new data through the model and checking the accuracy of its (classification) decisions. Final testing of the model took place in summer 2020.

These efforts resulted in a system that automatically classifies every new EDRS entry with more than 90% accuracy and displays the result immediately to the EDRS user. There is no change in how the driller enters the data; the change is in how the company and its customers are able to access, analyze and manipulate the data, both new and historical. Ms Moffat said any attempt to analyze such a large set of free-text data without machine learning would have been “an impossible task.”

Gaining operational insights

In some cases, the model picked up on subtle implications that the human testers had overlooked or misclassified. The automatic classification system also revealed some previously unknown correlations that helped the team build a picture of efficiency bottlenecks. When dealing with a well issue, for example, there would often be a rig issue shortly after. Some correlations were not unknown, but the company had never been able to demonstrate and visualize the relationships before.

“When we looked at the broader picture, at certain depths of each well, we were finding an issue where rigs were encountering waiting times – waiting for a certain tool to be delivered or waiting on a decision,” Ms Moffat said.

Once highlighted as an issue, such waiting times could be preempted in the planning stages before they happen. Ms Moffat described the AI-enabled analysis of free-text data as contributing to a step-change in how KCA Deutag delivers value from technology to its customers. “It’s a completely new way of bringing information to the table and certainly a part of our Customer Centricity approach.”

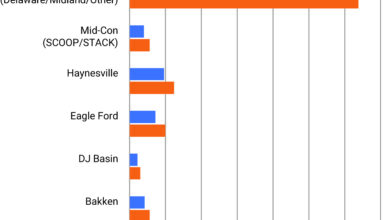

To make the free-text categorization constructive for operations, the project team collaborated with the IT department to introduce an interactive dashboard in late 2020 that enables users to conduct their own investigations into the data to identify trends and previously hidden issues. The dashboard looks like the shape of the well, with each dot representing a comment within the reporting system that is color-coded to reflect its assigned category.

A dashboard user could select options to view entries by country, by rig or by category and could even drill down to a specific well or phase of a well. For example, a user could click “well issues,” and the dashboard would zoom in with a summary that could include that particular well, rig and client, depth of occurrence, section of the well, and the reason the model has assigned it to that classification.

Moving forward

The project places KCA Deutag at the leading edge of companies putting natural language processing and machine learning to practical use in an operational setting.

“It’s something quite unique,” Ms Moffat said of the AI-enabled system. The machine learning model has become part of the company’s “well of innovation” program that features a suite of technology and data science approaches that target delivering additional value to customers. This includes the reduction of overall well NPT, which is an area where the drilling contractor had not been traditionally involved.

She added that the machine learning techniques developed by KCA Deutag and Endila could be applied to customers’ or other third parties’ drilling reports or other types of records that feature human-entered text, such as HSE or inspection reports. For now, however, the company is focused on drilling down even further into the rig and well comment categories to see what specific issues come up.

“We’ll be doing more analysis on each category to make sure we get the most out of what we’ve developed already, and the remarkable part of it all is that the whole project was conducted remotely while we were all working from home,” Ms Moffat said. DC

Click here to view a video about KCA Deutag’s AI project.