Huisman to provide composite casings for pilot well for carbon storage

Huisman has been awarded a contract by Carbfix for the delivery and installation of Huisman Composite Tubulars. The pipe system will be installed in the pilot well of the Coda Terminal, a large carbon transport and storage hub in Iceland.

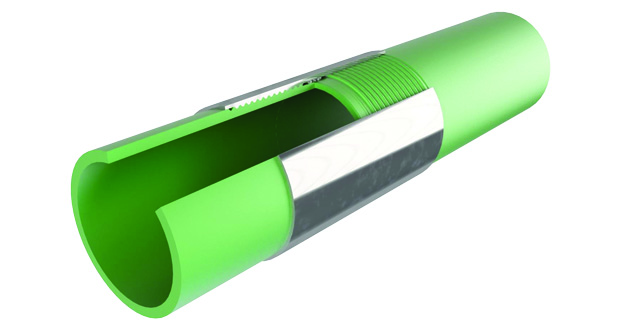

Huisman has developed in-house a fit-for-purpose downhole composite pipe system specifically for well construction purposes, to provide a flow path for the production and injection of fluids. By shifting from conventional steel to composite materials, the composite tubulars tackle corrosion problems and reduces scaling tendency.

After installation and cementation of the 9 5/8-in. composite casing, an 8 ½-in. open-hole section will be drilled to the target depth. This means that the bit and drill pipe will be run through the inside of the composite casing, a unique procedure made possible by the strong, fully composite pipe body.

Carbfix developed a process that turns CO2 into stone. CO2 is dissolved in seawater before it is pumped into a basaltic bedrock formation through a network of injections wells. Once in the subsurface, the injected CO2 reacts with the rock, forming stable carbonate minerals, thus providing for safe, long-term storage. Page 2 of 2

The Coda Terminal pilot well will be located near Straumsvík. At full scale, the terminal will have the capacity to inject 3 million tonnes of CO2 per year for permanent mineral storage.