Drilling & Completion Tech Digest

Expro sets record for deployment of heaviest casing string, launches remote clamp installation system

Expro recently saw two successful deployments of its technologies.

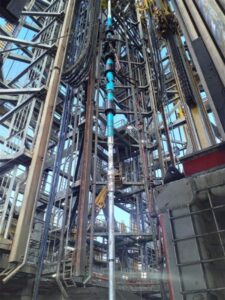

In one project, the company achieved a world record by deploying the heaviest casing string to date, using its advanced Blackhawk Gen III Wireless Top Drive Cement Head with SKYHOOK technology. The record was achieved onboard the Transocean Deepwater Titan in the US Gulf.

With a maximum hook load of 2.849 million lb, the casing deployment exceeded all prior offshore records. The Gen III cement head with SKYHOOK now stands as the only 3 million lb combined rated cementing system in the industry, according to Expro. It is optimal for rotating while cementing drill pipe-deployed casing strings or liners. Combined with the SKYHOOK Cement Line Make-Up Device, the wireless cement heads eliminate the need for personnel above the rig floor.

The Gen III cement head was engineered for full pressure and tensile capacity – 15,000 psi and 3 million lb. Unlike other systems that require derating under high-pressure conditions, the Gen III system maintained full performance and structural integrity throughout the operation.

In another project, Expro successfully completed the first full deployment of its Remote Clamp Installation System (RCIS). Developed by the Frank’s Tubular Running Services division of Expro, the RCIS offers a solution for smart well completions requiring real-time monitoring and control of downhole tools from the surface via control lines.

The RCIS eliminates significant manual intervention traditionally needed to install control line clamps on tubing during completion operations. By fully automating this process, the RCIS enhances the efficiency of the completion installation and reduces risk.

The initial deployment of the RCIS took place in the UK’s North Sea during Q4 2024 as part of a test trial. The project was delivered in collaboration with BP, which also partially sponsored the development of the RCIS technology.

Building on that success, the RCIS was deployed again in Q2 2025, by another operator in the North Sea, where Expro ran a completely hands-free upper completion at up to 15 joints per hour with zero nonproductive time or damage to any of the control lines. This increased running efficiency by 25%. The control line clamps were installed remotely, reducing installation time by approximately two minutes, or 50%, per clamp.

Project launched to develop digitally enabled, additively manufactured propeller

A consortium of industry and research leaders has announced a project to develop the world’s first digitally enabled, additively manufactured (AM) propeller. The Digitally Enabled Efficient Propeller (D.E.E.P) project will pioneer a new generation of marine propellers manufactured using advanced additive manufacturing processes, integrated with digital twin technology.

This innovation aims to transform propellers from passive hardware into smart, cyber-physical systems capable of monitoring their performance throughout their operational life.

The D.E.E.P concept has secured funding from Innovate UK, part of UK Research and Innovation through the Clean Maritime Demonstration Competition, to launch the Techno-Economic Feasibility Study of Manufacturing Digitally Enabled Efficient Propellers.

Crucially, the project will investigate the technology readiness of multiple AM processes for the highly regulated and complex maritime sector, benchmark their performance against conventional casting methods, and establish a clear pathway toward classification approval and type certification. This approach will ensure that the project not only delivers technical innovation but also creates a credible framework for industrial adoption and regulatory compliance.

Led by Enki Marine, the consortium brings together: Stone Marine Propulsion (design and market validation), TWI (materials testing and manufacturing processes), DEEP Manufacturing (manufacturing processes and production scaling), Authentise (digital thread and AI-driven monitoring), ASTM International (standardization and certification) and Newcastle University (hydrodynamic modeling and validation).

The project began in September 2025, with the first phase focusing on evaluating AM processes. Subsequent stages will validate the demonstrator on Newcastle University’s research vessel, with the long-term aim of enabling type approval and scaling production for commercial adoption by the global fleet.