Saturated market, policy challenges push KCA Deutag eastward

Contractor seeks expanded presence in Eastern Europe, Kazakhstan as unconventionals development stalls in the West

By Katie Mazerov, Contributing Editor

Jeroen Holwerda is the Regional Manager for Europe and Kazakhstan at KCA Deutag.

Jeroen Holwerda is the Regional Manager for Europe and Kazakhstan at KCA Deutag.

What do you see as the most significant issues facing the European land market today?

There are several challenges – one of the most significant being the increased number of rigs and drilling contractors now available in Europe, combined with the low number of wells being drilled or scheduled to be drilled. This over-saturation of the market is partly a result of smaller, water-well drilling contractors entering the E&P and geothermal sectors. KCA Deutag is countering this trend by being the contractor of choice, providing quality services and competent crews to deliver high value for our customers whilst operating safely and succeeding globally.

Currently we have a fleet of seven land rigs in Europe, of which the majority are carrying out conventional work in The Netherlands and Albania, where we recently drilled two wells with a 2,000-hp installation. Albania is an established market with traditionally shallow wells. However, new exploration is in deeper formations.

Another challenge, particularly in Western Europe, is the difficulty in obtaining directives and the long decision-making permission process, which can affect the rate of development. This delay by governments in approving concessions has a huge impact on the European market because operators can’t execute their projects in line with their schedules. Public opinion and concerns about drilling play a great part in this trend, despite the fact that Europe remains dependent on Russia for energy. Eastern Europe, however, is more open to oil and gas development. For that reason, we are looking to develop a greater presence in that region, specifically Albania, Bulgaria, Hungary, Romania, Ukraine and Turkey.

How have declining oil prices impacted the European market?

Declining oil prices are contributing to the downturn in activity across Europe. This price drop is concerning for the industry, but it may also open up new opportunities, such as the geothermal market in Europe. A lot of geothermal projects are being considered. For example, cities in southern Germany are looking at geothermal wells to generate electricity and greenhouse farmers to generate heat. With our combined drilling services model, we see the geothermal sector as a potential opportunity as the majority of these projects require an integrated solution.

How significant are Kazakhstan’s hydrocarbon resources, and what opportunities exist to develop those resources?

Kazakhstan has tremendous oil and gas resources, with an estimated 30 billion bbl of oil and 85 trillion cu ft of natural gas from the Tengiz, Karachaganak, Kashagan and Imashevskoye fields. There has been a lot of development in the country in the past decade, primarily from conventional wells. The country has a good long-term economic strategy, with growth expected through 2050. This growth trend is putting pressure on the industry to deliver wells and has increased the demand for modern, 2,000- and 3,000-hp AC rigs, which provide greater efficiency and reduced environmental impact. The current lack of modern and reliable technology is opening up opportunities for us, and we are looking to boost our presence in the Kazakhstan market. We currently have one 3,000-hp rig in the country, and in 2015, we plan to bring in two or three more rigs from other locations.

The requirements for operating in Kazakhstan have also changed because the government, in an effort to secure public support for oil and gas development, has now mandated that all new projects be set up as joint ventures with local companies. We welcome this, and KCA Deutag is actively working with potential partners to expand our footprint in the country.

How does KCA Deutag balance the challenges and opportunities in Europe and Kazakhstan in terms of HSE, expertise/training, rig design and attitudes about drilling?

The two regions are very different and pose challenges that we, as a company, strive to address. Kazakhstan is ready for development but has strict local content requirements that raise the bar for training and expertise. We need to ensure that our crews operate at the high standards we provide to all our customers. A well-trained crew is especially important as rig systems become increasingly complicated and automated and as we want to bring new technology into the country. In light of the ongoing Big Crew Change facing the industry, we are making a concerted effort to ensure the transfer of knowledge to the next generation of rig crews. To support this, KCA Deutag has set up its own competency assurance program, which covers all disciplines and is in compliance with IADC criteria. Competition in the market is tough, but we believe KCA Deutag, with our ability to deliver modern rigs and improved performance, can assist Kazakhstan in fulfilling its strategic plans.

In Europe, training is less of an issue for us as we have a great training path for staff. However, the long approval process, in part influenced by a reduced public appetite for drilling, presents obstacles. KCA Deutag has a good environmental track record, and we try to indirectly influence public opinion by involving citizens in areas and villages where we are drilling. We invite them to well sites for tours, work on building positive relationships, minimize the impact on the local area and assure them that we operate in a safe manner.

Unconventional development in Europe continues to be challenging. What are the key issues for moving that sector forward?

Eastern Europe is eager to move forward with unconventional development, and Poland was one of the countries that emerged early on with high expectations. However, disappointing results have forced several majors, as well as smaller operators, to withdraw from that market. Production is simply not yet economic. In Western Europe, environmental concerns, especially in the UK, Germany and France, have delayed progress, even though stimulation has been done in the past on conventional wells. With unclear political directives, issues of land ownership and delays in decision-making, the unconventional market has not been able to take off in the region yet.

With heightened global focus on HSE, what are some of the key initiatives KCA Deutag is undertaking to ensure operational and employee safety?

At KCA Deutag, we are very focused on process safety, which we refer to as operational integrity. We are committed to ensuring safe, effective and trouble-free operations for our customers and employees, and work in line with European and local requirements and legislation. It is critical that our assets are maintained to the highest standard and that processes and procedures are executed properly. From an HSE point of view, we have implemented personal safety into our day-to-day business, and our crews are committed to it. We utilize the bowtie safety method for identifying risks and necessary mitigating actions. These include accident hazard sheets for all key operations, including drilling, cementing and casing running, as well as identifying safety protocol tasks and who is responsible for ensuring they are carried out. This philosophy has been quite successful at KCA Deutag, with managers leading by example. We have established a strong safety culture and track record, and in so doing, believe we have set ourselves apart from the market.

KCA Deutag also has established training schools in strategic locations across the globe, using DART, the company’s approach to drilling operations training. This service offers simulator-based well control training and simulations with drilling equipment for rig crews and operators. Our goal is to set the standard in training so all our employees fully understand the issues we face instead of just passing exams.

How do KCA Deutag’s new rig designs reflect the focus on safety?

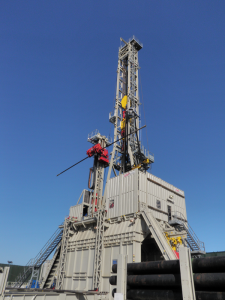

There is an increasing demand to adopt the “hands-off” approach to drilling operations on rigs. This trend is reflected in our newest rig, the T-700, which we introduced in early 2012. The rig, which is operating in The Netherlands, includes highly automated processes, such as systems and barriers for shutting down an operation in the event of an equipment failure. The rig floor and pipe-handling areas are controlled remotely from the driller’s cabin, keeping crew members out of harm’s way in these high-risk areas. Processes and procedures enable sequential activities to occur simultaneously. This results in improved tripping time and operational speed, which is a huge step forward.

The design has allowed us to reduce crew size by 15-20% compared with conventional rigs, which further minimizes the potential for accidents.