Steering capabilities broaden drilling with casing/liner applications

By Katie Mazerov, contributing editor

Image courtesy of Schlumberger

To drill conventionally or not to drill conventionally. As industry increasingly finds itself in depleted and unstable formations, reactive shale plays and challenging subsea environments, more and more operators are facing the question of whether to switch from traditional drilling methods to drilling with casing (DWC).

“When we talk about reaching that tipping point of being able to solve problems with conventional methods versus solving problems with DWC technology, it’s not a question of if – but when,” said Eric Moellendick, director of technology, Casing Drilling, for Schlumberger. “Some of the world’s largest intervals are becoming harder to drill conventionally, and it’s never going to get easier to drill in these environments.”

Drilling with casing, and now with liner, has traditionally been a niche technology used to isolate and produce trouble zones. With the advent of steerable DWC and drilling with liner (DWL) systems, the concept continues to gain credibility among operators as a versatile technology offering a multitude of benefits in complex wellbores, including reduced drilling time and drill pipe tripping, increased well control and better wellbore stability.

Schlumberger’s steerable Casing Drilling technology has seen successful implementation in directional wells, while Statoil and Baker Hughes partnered to develop a steerable liner system for achieving wellbore stability in challenging North Sea wells. Weatherford also is seeing more demand for its drilling with casing and liner technologies.

Schlumberger, which last year acquired the Casing Drilling division of Tesco Corp, defines DWC technology in several levels, the first being the common practice of going back into a conventionally drilled wellbore and rotating and reaming the casing to the bottom. Drivers of innovation include the need to minimize lost returns and increase wellbore stability while drilling.

“We call this the plastering effect borehole-strengthening process, which allows operators to drill through areas of lost circulation, unstable formations and highly reactive or sloughing shales,” Mr Moellendick said. The process plasters the drill cuttings into the formation face, increasing near-wellbore stability.

Choosing the appropriate method is “all about engineering the level of technology for the specific application with an integrated approach,” he continued. “The value propositions of faster drilling and better results in hard-to-drill formations reduce NPT and flat time that come with conventionally solving problems with less effective techniques.”

However, transitioning from conventional methods to new is not always an easy proposition. “From an operator’s perspective, changing the entire drilling system changes every facet of drilling, from the well design to the mud program,” he noted. “Sometimes it takes a compelling event to accept that degree of change.”

A turning point

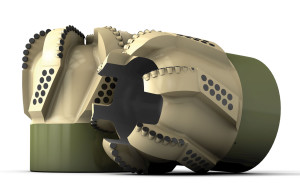

For an operator in Colorado’s unconventional Niobrara play, that turning point came after repeated drilling difficulties in problem formations. Using the non-retrievable Casing Drilling system, which involves rotating the pipe with the top drive and using surface equipment to grip the casing with an XCD3 drillable casing-while-drilling bit on the end of the casing string, the operator was able to drill the well to total depth (TD), land the casing in place and cement the interval. This was achieved in 10 days after spending more than 60 days trying to do the same project with conventional methods. The operator subsequently used the technique on a second well and drilled the entire interval in seven days, saving more than $3 million compared with the cost of the first well.

With Schlumberger systems, a set number of feet can be drilled in one run, at the same angle, but with no logging capabilities. Those limitations led to the development of directional DWC using a rotary steerable logging assembly or bent mud motor to latch into the bottom of the casing. The casing provides downhole torque and rotation to drill. “This allows us to drill directional wells with casing and get real-time logging information,” Mr Moellendick explained. “We can easily make two or three drill bit runs to achieve the wellbore construction objectives.”

The directional DWC technology has become common for well construction offshore Malaysia, where shallow surface wells are routinely drilled from the conductor to 1,500 meters using a seawater mud system. The system also allows for faster cuttings removal in shallow intervals with large casing sizes that have a very narrow annulus. “We can only drill a hole as fast as we can clean it, and with this method, we can achieve directional performance and drill these wells 500% faster than with conventional methods,” Mr Moellendick said.

For the deepwater market, Schlumberger has drilled several successful field-test wells using a new liner drilling system that received a Spotlight on New Technology Award at the 2012 OTC. The system allows an operator to simultaneously drill a directional wellbore and run the liner in a single trip, with the option to set the liner in tension anywhere in the parent casing. The bottomhole assembly (BHA) can be retrieved without having to pull the liner to the surface. “This provides a huge time savings for the operator, as opposed to tripping the liner to the surface,” he explained.

The 80/20 rule

As operators place higher priority on well construction goals, Weatherford is seeing increased demand for its DwC and DWL systems, according to Steve Rosenberg, global drilling reliability manager for the well engineering and project management team. “I call it the 80/20 rule,” he said. “Twenty percent of the time in problem wells, an operator can drill using conventional methods, but 80% of the time is increasingly encountering issues such as lost circulation, stuck pipe and instability – problems that can take a long time to solve and have high probability of failure with conventional methods.”

Using the company’s Total Depth philosophy, which encourages early collaboration between operators and service companies, Weatherford believes it can build DWC and DWL solutions into the well design, potentially delivering significant time and cost savings, Mr Rosenberg said. “For example, we now have software where we can further enhance the plastering, or smear, effect in a well by designing the particle size distribution created by casing and liner drilling based on the formation’s fracture size, permeability and porosity properties. This is a huge step-change in wellbore strengthening technology.”

Key markets for Weatherford’s DwC technology include US land, Gulf of Mexico (GOM), West Africa, Russia and the Asia Pacific, where it has been used for batch drilling. On a platform rig for an operator in China’s Bohai Bay, the technology was used to drill 24 sections with one-size casing string, saving 23 days of rig time and 65% of the total time to execute the well plan over conventional drilling.

For subsea environments, Weather-ford’s SeaLance Subsea DWC system is being used to “soft land” the seal assembly or a high-pressure wellhead housing to avoid potential damage if landed while rotating. “This takes all the benefits of a DWC system on land or shallow water and applies it for deepwater,” Mr Rosenberg said. The system enables a 20-in. casing string and its high-pressure wellhead housing to be drilled to depth, cemented and released in a single trip. A retractable shoe joint allows the casing to be drilled with the high-pressure housing attached to it.

Once the wellhead housing is about 10 ft above the low-pressure housing, a sequence of ball-dropping and hydraulic events is initiated to retract the shoe joint and soft land, without rotating, the high-pressure housing onto the low-pressure housing and cement it in place using conventional cementing methods.

Drilling deeper

The system also mitigates shallow gas or water flows because of the tighter annulus created by using a larger casing size relative to hole size. “More equivalent circulating density can be generated per unit pump rate, so there is less chance of water or gas flows,” he said. “We can drill deeper than we can conventionally because we’re using less mud, and we can potentially eliminate a casing string because we can set the casing deeper in an interval with a higher fracture gradient than could previously be attained using conventional drilling methods.”

Weatherford’s hydraulic liner drilling system has been deployed in several offshore markets, including the GOM, where new US Bureau of Safety and Environmental Enforcement (BSEE) regulations stipulate that DWC designs for shallow and deepwater wells include shear rams to sever the casing. The company believes that regulation and the fact that liners require fewer connections than DWC have been key drivers for deploying liner drilling in the offshore sector.

A 5 ½-in. liner system was used in a GOM well to drill through and isolate a 17-lb shale and a 2-lb/gal sand section in the same hole section. The operator had tried to drill the formation conventionally with a 17-lb mud, but the drill string became stuck in the sand.

A 12-lb/gal water-based mud was designed for the DWL operation. This fluid system was low enough in weight to not fracture the sand but had sufficient weight to manage the pressured shale. The liner reamed and drilled 113 ft, the last 21 ft through the 2-lb sand with no fluid losses, and set the pipe in the shale. The operator was able to complete the well with the planned 3 ½-in tubing.

For both the DwC and DWL systems, which are compatible with Weatherford’s drillable casing bits, the company runs torque and drag, hydraulics and cyclic fatigue models in the planning stages to ensure the limitations of the systems are not exceeded. “We want to ensure nothing comes apart in the well while we’re drilling and that the systems can handle the mechanical rigors of drilling from a tensile, torsional and compressive standpoint,” Mr Rosenberg explained.

Fatigue modeling is especially important for making connections. “Because we’re rotating the casing or liner for thousands of revolutions, we need to verify that the connections can handle the cyclic stresses.”

Steerable liner in North Sea

Baker Hughes began field-testing its steerable drilling liner (SDL) system in 2009 in the North Sea. The system was jointly developed with Statoil, which was encountering drilling conditions and reservoirs that were being significantly affected by wellbore instability. The system, which is expected to be fully commercialized this year, drills while simultaneously sealing off trouble zones and reduces the number of trips or sidetracks needed to complete an interval. It combines a full 3D rotary steerable system with a liner and provides MWD and LWD capabilities. A full suite of LWD tools can be added if needed.

The system has a retrievable BHA, which enables drilling through trouble zones with low pressure or unstable shale or coal layers, explained Muntasar Mohammad, Baker Hughes product manager for drilling services. The system can drill and log complex 3D well profiles with a liner attached to the drill string. It is available in 9 5/8-in. and 7-in. sizes.

“We believe steerable liner systems will be a significant growth area,” said Svein Steen, the company’s product line manager for drilling services. “We are seeing the market moving toward this technology as more operators are experiencing critical wellbore stability issues, which are contributing to higher costs and NPT. We often see that conventional drilling systems won’t provide a solution for these unstable formations and scenarios that have marginal operational envelopes for drilling and completion.” Although applicable both offshore and in land wells, the system is initially being targeted for the offshore market.

“Drilling with a liner has a number of advantages and is applicable in any location at any depth of the wellbore,” Mr Steen continued. “For example, the SDL liner drilling system doesn’t require any top drive modification or specialized rig equipment and can be deployed on floating drilling units without compromising well control. Also, when using a liner solution, some operators are able to seal off the annulus between the open hole and the liner with a packer. Compared to a casing solution, this provides an additional barrier to prevent hydrocarbons from migrating into the well if the cement is channeled.”

The SDL achieves a plastering effect by smearing the cuttings into the formation, where they serve as an enhanced filter cake. This reduces fluid losses and the volume of cuttings that is returned to the surface. Reduced fluid costs and chemical additives that are required to maintain wellbore stability are other benefits when drilling with a liner.

The technology also is well suited for areas that can’t be drilled conventionally and where reserves are otherwise unreachable. In one of the first offshore field tests for Statoil, Baker Hughes used the 9 5/8-in. SDL system to drill – and simultaneously steer and log – a horizontal 3D well through an unstable shale section in the North Sea. Statoil initially was able to drill the well with conventional methods, but the formation collapsed after pulling out of the hole to run the liner. Approximately 354 ft of new formation was drilled using the SDL system on a 4,029-ft liner with an AutoTrak rotary steerable BHA, OnTrak formation evaluation suite and CoPilot real-time drilling optimization tool. Using a total of 4,029 ft of liner, the well was drilled to TD and cemented in place. “In this case, the SDL allowed us to drill through the shale and access the reservoir’s sweet spots of oil,” Mr Mohammad said.

In late 2012, Baker Hughes used the SDL with the AutoTrak steerable BHA to drill an 824-ft liner into an 8 ½-in. section of unstable shale, where getting the liner through the shale had proven difficult and often resulted in sidetracks due to wellbore collapse and/or pack-offs. The mitigating action has been to replace the well path well above the reservoir base, therefore limiting drainage to the reservoir.

“The SDL system allowed drilling through the shale section and sealed it off immediately before problems started to develop,” Mr Mohammad noted. “The well is expected to produce at least 350,000 bbls, and possibly up to 1 million bbls, during its lifecycle – oil that would otherwise have been left in the ground.”

“In the past, casing and liner drilling technologies weren’t where they needed to be to meet industry demands,” he added. “However, today, there are more fit-for-purpose solutions to address wellbore instability issues worldwide.”

Casing Drilling and XCD3 are marks of Schlumberger. DwC, TOTAL DEPTH and SeaLance are trademarked terms of Weatherford. AutoTrak, OnTrak and CoPilot are trademarked terms of Baker Hughes.