Logging data linked in real time mitigate drilling complications

By M. Ribeiro, V. Costa, R. Guedes, P. Bittencourt, OGX; Paolo Ferraris, Ana Beatriz Guedes Domingues, Schlumberger

The Brazilian petroleum industry has entered a new era of success exploiting shallow-water oil reserves in the Campos Basin, utilizing methods enhanced by advanced software and buttressed by a likely world-first application of neural networking to mitigate drilling complications.

The combination of technological innovation and groundbreaking methodology has enabled the industry to evaluate complex carbonates and achieve higher-than-expected net pays in the Quissamã Member of the Macaé Formation.

Following a pilot well, the first completed horizontal well resulted in an estimated maximum achievable flow rate of 40,000 bbl/day of oil without movable water. Net pay was 80%, exceeding the initial goal of 65%.

Operator OGX Petróleo e Gas faced the task of identifying target zones in an Albian (Upper Cretaceous) carbonate reservoir. The complex reservoir section consists of a lower half dolomitized with metric thickness shoaling upward cycles from matrix to grain-supported rocks. The upper segment includes mostly beds of grain-supported limestone with secondary siliciclastic richer beds.

The average porosity is 15%, occasionally reaching 25%. Cores and electric/ultrasonic image logs in the pilot well identified closed and oil-bearing open fractures.

Pilot well

The S-shape pilot well crossed stratigraphically the whole reservoir, with the team from OGX Petróleo e Gas and Schlumberger using data to identify a target zone for a 1,000-meter lateral in the horizontal well.

The team utilized Schlumberger’s logging-while-drilling (LWD) and wireline technologies to compare the two, characterize log reservoir signatures before and after mud filtrate invasion, and support real-time horizontal well petrophysics interpretation for geosteering decisions in the subsequent well.

The bottomhole assembly (BHA) in the pilot well consisted of a PDC bit, point-the-bit rotary steerable tool, LWD laterolog imager, LWD nuclear magnetic resonance (NMR) tool, LWD multifunction formation evaluation tool and measurement-while-drilling (MWD) tool to transmit real-time data. An optimized physical transmission rate was selected to obtain real-time data similar to memory data.

The challenge was to understand the multi-mineral composition of the rock and identify intervals with the largest production potential.

Lithology was defined in the pilot well using capture spectroscopy by a pulsed neutron LWD source, coupled with high-resolution NaI detectors. NMR tools were chosen to analyze the rock texture and determine the connectivity of the pore structure.

The deployment of the LWD tool was a first for the operator, who used synthetic oil-base mud (SOBM) in the pilot well.

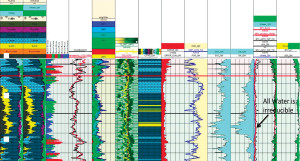

In Figure 1, the two boxed sections show the top two potential target layers. The area in the orange box is a layer of predominant calcite lithology and meso-pores texture. The zone indicated by the green rectangle was dolomitized with the predominant texture consisting of macro-pores.

Differences in textures indicate effective permeability in the second layer up to 10 times larger than the top interval of similar porosity, leading to a decision to bypass the top layer in the horizontal section.

The pilot well also provided an opportunity to validate the new NMR measurement available in Schlumberger’s proVISION Plus magnetic resonance while drilling tool.

The tool, consisting of a 6 ¾-in. collar centered in the borehole using two spiral stabilizers, performed a focused measurement over a resonating ring zone 14 in. in diameter and roughly a ½-in. thick.

The magnetic field has a low gradient, minimizing diffusion effect. The cylindrical symmetry allows the collar to rotate freely without affecting the measurement.

In the water zone, the LWD NMR and combinable magnetic resonance (CMR) data were directly comparable and equivalent. The bound fluid volume (BFV) measured by CMR overlaid irreducible water measured by the magnetic resonance while drilling tool, demonstrating that, under comparable conditions, the two measurements are closely interchangeable and will lead to consistent results.

After proving data overlay in the water zone, the same measurement was observed in the oil zone.

With data in hand, the operator targeted the layer with partial oil re-invasion, good dolomitization and an overall combination of the best petrophysical properties.

Horizontal well

Two kilometers separated the discovery well and the landing of the horizontal well. To reach the aggressive net pay goal, the team made extensive use of real-time petrophysics, integrating both the LWD and wireline data and updating models to support geosteering decisions.

Schlumberger’s RTGS real-time geosteering software was used to build a geological model using the seismic data for its structure and the pilot petrophysical data to propagate properties along the trajectory.

A petrophysics analysis was run in parallel to guarantee the best well placement. NMR was used for net pay count and pore-typing; spectroscopy for elemental analysis, leading to facies recognition and matrix density determination; and images to compute dips and adjust borehole inclination.

The operator opted for a low damaging water-base mud (WBM) instead of SOBM. Textural analysis was performed using the same method and achieved a response similar to the pilot hole.

Identified were zones with calcite lithology close to the top, a combination of calcite and dolomite composing the second reservoir for the sweet spot, and bottom intervals containing a highly dolomitized zone.

The pilot well showed that some intervals with high gamma ray could correspond to zones with high resistivity, atypical of shales. Capture spectroscopy indicated a high quartz content but not clay.

Consequently, these zones could well contain movable oil and contribute to net pay. The true stratigraphic thickness (TST) of the top carbonate reservoir was estimated at around 25 meters, dipping 22° from horizontal in the direction opposite to the well trajectory at reservoir entry.

In the 12 ¼-in. section, the shoe was successfully set at a level corresponding to the second layer from top.

The initial challenge in the 8 ½-in. horizontal section was to build the angle with the maximum allowable dogleg severity (DLS), based on completion limits, to track the upper section of the reservoir, which was dipping against the trajectory for the initial 300 meters.

Resistivity images allowed computing relative dips in real time and monitoring the progress of reservoir structure folding. Well deviation increased from 82° at landing to 89° at 300 meters from it.

Spectroscopy and NMR provided formation evaluation in real time, in addition to density, neutron porosity and 2Mhz propagation resistivity. The best reservoir intervals were identified and net pay accrued using NMR-derived free fluid volume (FFV).

The meso- and macro-pore intervals were easily recognizable. Spectroscopy confirmed the rock dolomitization characteristic of the optimum layer. All water was irreducible. Permeability based on NMR texture was computed using a pore-partitioning for permeability analysis algorithm that can predict the enhanced permeabilities observed over macro-pore intervals.

After the first 300 meters, the trajectory was dropped to avoid exiting from the reservoir roof.

A tool hardware failure at this point resulted in no NMR data being available for steering or evaluation over the later part of the well.

Permeability modeling

Instead of a costly trip to replace the faulty tool, the team used all previous data to reconstruct NMR-equivalent data using a neural network approach in real time, which the companies involved believe was a world-first application.

Data from six spectroscopy mineral fractions were selected to characterize dependent lithological formation properties. Bottom-quadrant densities (ROBB) and thermal neutron porosity (TNPH) were selected because formation density and porosity are related to FFV. Sigma was added because invasion affects shallow measurements.

Estimating logs using neural networks requires the definition of the structure of the network, followed by training on the data set with check to verify convergence of the training process and finally application of the trained network to independent data sets, all while checking for consistency.

To select an interval where all the logs had reliable values, the rat hole section was excluded. The first target variable was FFV. The same variable was checked against known values and not chosen for training. The match (Figure 2) was very encouraging.

The synthetic FFV obtained through the neural network method, implemented using the K.mod module available in the Schlumberger Techlog wellbore software platform, showed only minor discrepancies from spectroscopy, with a lower vertical resolution than NMR due to depth averaging.

The K.mod module within the Techlog software platform has consistently demonstrated its capacity to extract essential information from log data to predict non-recorded parameters and reconstruct missing or poor-quality measurements to compensate for bad hole conditions, environmental effects, acquisition problems and other factors. The software also allows for controlling of scale shift management from core to reservoir scale and comparing well log and core data to reduce the need for coring and plug analysis.

Principal component analysis was performed to determine if input channels were optimal. Figure 3 shows the results. The position of the dots illustrates how the different variables correlate to one another.

The evidence that most of the dots are occupying different spots in the correlation ellipsoid indicates that the variables are independent and their contribution significant.

Eventually, in this case only, the pyrite weight fraction is closely related to clay content and not completely independent from it. Results, however, were practically unchanged removing this channel, so this combination of inputs was used in the final evaluation.

The same network structure and principles were also used to estimate NMR permeability. Figure 4 already displayed the synthetic permeability on top of the one directly derived from NMR.

Over this interval, estimated permeability using neural network and spectroscopy matches NMR data, with the exception of the macro-pore intervals, where the achievable dynamic range is slightly reduced. Figure 5 shows a deeper section of the horizontal well.

Below the last available NMR data permeability, FFV and BFV were estimated using the K.mod method. The results show reliable and conservative permeabilities and confirmed the absence of movable water. With these data, it was possible to continue drilling with confidence in formation evaluation.

After drilling, the contingency run with a new NMR LWD tool was canceled because the operator was confident that collected data was sufficient for a proper evaluation.

RTGS, Techlog and proVISION Plus are marks of Schlumberger.

This article is based on SPE OTC-22738-PP, presented at the SPE Latin American and Caribbean Petroleum Engineering Conference, Mexico City, Mexico, 16–18 April 2012.

Dear Sir,

Respectfully, through this email we would like to introduce ourselves as one of the leading companies in the field of Well-Log-Digitization; situated in New Delhi in India. We have been digitizing all oil well logs (Electric Log, Sonic log, Mud Log, Acoustic Log, Array Log, Density Log etc.) for over a decade. You can give your data in the form of-jpeg/bmp/tiff in colour/gray/B&W/film/disk etc; and we will convert them into digitalized files of international standards with required parameters and latest versions –NLG, WLG, LAS-1.2, LAS-2, LIS. We use Neuralog Digitizing System to convert all analog images to company standard digital formats.

Throwaway prices: We charge reasonably low price. There will not be any starting fee, extra processing fee or any other hidden fee. You just need to pay us for each 100 curve ft data. It will surely be proved a cost effective term in your business.

We are known for our best quality output in the shortest period of time. We are always eager to have new contracts with the company like yours. You can check our potential through a sample job first. Kindly give us a chance-&-you shall find us a valuable vendor !

Kindly see the attachments and know What we do and How we do !

Best Regards,

Sandeep Sharma

R S Datum

C-44, Satya Enclave,

Swarn Park Industrial Area.

New Delhi-110086,

India.

Call us : +91 011 65097374

Mobile: +91 09971097374

E-mail : info@rsdatum.com

: rsdatum@ymail.com

Visit us : http://www.rsdatum.com