Petrobras enhances human factors thinking to improve safety in MPD operations

Analyses of prior incidents lead the operator to take a fresh look at how contextual factors at wellsite can influence human performance

By Stephen Whitfield, Senior Editor

Risk analyses have long been incorporated into the wells engineering process to prevent and mitigate risks in offshore operations. Some analyses, like HAZID/HAZOP, account for the risks associated with using equipment. Other analyses, like FMEA/FMECA, focus on new equipment builds. BOPs and other equipment have their own reliability analyses. Companies also run an exhausting battery of tests on MPD control systems prior to deployment.

However, none of these analyses consider human error’s role in things going wrong, said Ivan Sales, MPD Engineer at Petrobras. Because of this gap, these analyses fail to propose measures to avoid failures caused by human factors. Yet, humans are part of the system, so they will act and respond to issues according to context, and risk analyses should provide that context, he said.

“When we’re talking about MPD, there’s a lot of complexity,” Mr Sales said, noting that organizations cannot expect any specific individual to handle every MPD operation flawlessly. “So, we need to know what to do to make sure something doesn’t go wrong.”

At the SPE/IADC Managed Pressure Drilling and Underbalanced Operations Conference in Rio de Janeiro, Brazil, on 17 September 2024, Mr Sales discussed Petrobras’ efforts to incorporate human factors into its MPD operations. These efforts included a comprehensive review of deepwater wells drilled with MPD in various locations offshore Brazil from 2020-2023. Petrobras looked at how human errors are often the sign of organizational or technological issues, and the operator proposed methods to mitigate them in MPD operations.

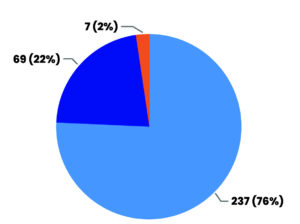

All wells reviewed involved some kind of incident, categorized into three areas: human error (an error in personnel executing tasks on the rig), project error (an error that came from planning) and equipment failure. The majority of the errors recorded (76%) came from equipment failure, but the review also found that 22% contained human errors.

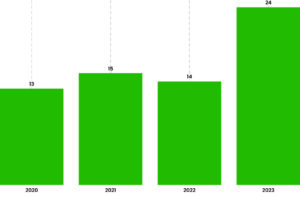

Further, the number of total human errors on the MPD wells showed an upward trend – there were 13 in 2020, 15 in 2021, 14 in 2022, and 24 in 2023. The jump from 2022 to 2023 was particularly noteworthy given that the number of wells drilled with MPD did not see a similar increase – 18 MPD wells were drilled in 2022, 19 in 2023.

Especially given the training mechanisms that were in place for personnel working on MPD, both companywide and industrywide, the trend indicated a cause for concern. For instance, Mr Sales cited a pair of API standards released in 2017, RP 92M (MPD operations with Surface Back-pressure) and RP 92S (MPD – Surface Back-Pressure with a Subsea Blowout Preventer) as providing key guidance for the industry. He also noted that Petrobras and its MPD providers had also began adding simulator-based training to bolster traditional classroom training.

“We’ve been increasing our training hours on MPD, focusing on our procedures for years,” Mr Sales said. “We have several API standards, and we have a core curriculum for MPD. But the human failure in MPD is not decreasing. That leads us to believe that, maybe, the approach we have today is not enough.”

The solutions commonly used to mitigate human error include increasing crew training and writing new procedures. However, Mr Sales said these solutions do not decrease the possibility of human failure to occur. Since human cognition is limited and it is impossible to account for all possible outcomes for an MPD operation, he said it was “utopic” to believe that humans will have enough time to read all failure reports, absorb the information and apply it to subsequent operations.

Even in instances where the crews are well trained and the procedures are complete, errors can still occur. Mr Sales pointed out one particular case from a well that was reviewed, where the operation required pressure loss to be measured in the choke and kill line while drilling. The MPD system used flow measured in the mud pumps and calculated pressure loss in the annulus to apply surface back pressure and maintain a constant bottomhole pressure. The correct calculation for the annulus friction loss relied on the correct input on the flow in.

The review showed that, on occasion, a mud pump aligned to the choke line was incorrectly set by the operator in the MPD control system as mud was pumped through the drillstring. It induced the system to miscalculate the surface back pressure required and reduced bottomhole pressure, leading at times to an underbalanced situation.

Analyzing these cases, it was noted that the MPD operators in these situations were well trained – Mr Sales called the MPD supervisor manning the well “one of the best we had” – and the procedures were also complete.

As a result, Petrobras looked at ways to simplify the MPD supervisor’s job. It added a module to the rig’s control system that indicated visually if the correct pumps were set within the MPD system – a green dot on the screen indicated that the pump was set, a blue dot indicated that it was not set. Since then, the well has not experienced any underbalanced conditions.

The well highlighted the value of taking a human factors approach to MPD, looking at the contextual factors that can influence human performance in executing a job. In this case, the lack of a clear mechanism showing that the mud pump was set led the MPD supervisor to pump through the drillstring with an incorrectly set pump.

Taking this kind of human factors approach to MPD requires a shift in organizational thinking, however. Mr Sales said it requires companies to understand the complexity in operations and why people do what they do. Solutions for the challenges people face need to be designed with a systems approach, considering how the relations between the parts would be affected along with the operations.

For instance, if personnel are engaged in their first contact with real MPD field operations, the operator may need to take additional steps to ensure that the personnel are comfortable in performing the necessary tasks for the operation, even though they are formally certified on MPD operations. Additional training may also be needed if the MPD system undergoes any upgrades.

Standardizing phraseology is another example. Mr Sales noted that the informal way communications are normally handled between people can impair the understanding of what’s going on between drillers and operators.

“The thing about MPD is that, not everyone does everything the same way,” he said. “Look at the equipment requirements – are they the same for every operator? What about the software requirements? We need to ensure the communication about the MPD components and the drilling contractor’s data are the same for every component.”

Mr Sales also stressed the importance of continued communication within the industry, both from Petrobras and other stakeholders, about any lessons learned from analyzing errors in MPD operations.

“We don’t share everything, but I think we need to share as much as we can about our lessons learned. The problems that happen on our operations are all the same for our competitors.” DC

For more information, please see SPE/IADC 221426, “Evolving MPD with Human Factors Approach.”