Projects in GOM, Mediterranean showcase expanded value of MPD in optimization, efficiency

Integrated MPD solution helps to eliminate a casing string in one deepwater well, while MPD dynamic pore pressure tests help operator avoid contingency liner in another

By Ahmad Abuelaish and Carlos Sanguinetti, SLB

Operators drilling in deepwater face many challenges, including operational issues and pressure-related events such as ballooning, well integrity and fluid loss. These events can lead to higher costs or even jeopardize the drilling plan.

Today, these challenges are being addressed with advances in managed pressure drilling (MPD), which helps mitigate drilling risk and optimize drilling parameters by performing on-demand evaluation of the drilling window, conducting dynamic pore pressure tests (DPPT) and dynamic formation integrity tests (DFIT).

Since MPD’s early days, it has been viewed as a well control solution. Today, however, MPD is also providing operators with a pathway to greater drilling optimization and efficiency.

A recent case study in the Gulf of Mexico shows how MPD can further enhance efficiency by eliminating a casing string. This approach not only significantly reduces well construction time but also minimizes emissions and associated costs.

Similarly, in the Mediterranean, operators have been able to eliminate the need for a contingency liner while also drilling a well under budget.

Evolution of MPD

In the past several years, a step change in MPD technologies has paved the way for new capabilities.

One of the latest innovations is an integrated MPD riser joint comprised of the marine drilling riser and below-tension-ring rotating control device (BTR RCD). This solution includes controls to operate the integrated riser joint, manifolds and all surface equipment in a single platform while enabling bottomhole pressure to be balanced and managed at the surface.

New software and systems are also making it possible to automate control in complex environments. For example, SLB’s @balance Control MPD system can be configured for semi-automatic or manual control.

The industry has also made substantial efforts to advance early kick detection (EKD) capabilities, notably through the introduction of Coriolis flowmeters combined with software to filter signals and provide more reliable readings.

Gulf of Mexico case study

An example of using MPD for drilling optimization and efficiency is a recent case study in the Gulf of Mexico. A client was facing the issue of a weak formation’s narrow drilling margin, which presented the risk of pressure-related events such as ballooning, lost circulation and wellbore instability. This could have led to a costly non-productivity period of up to several weeks.

To keep its complex Gulf of Mexico project on track and on budget, the operator needed a solution that would improve safety and efficiency while drilling.

Working in collaboration with the operator’s drilling engineers, SLB deployed an MPD integrated system, the industry’s first complete integrated deepwater MPD solution from a single supplier and a common platform. This minimized the rig’s footprint while maximizing drilling efficiency and versatility.

The solution provided all equipment, software and systems in a single platform, including the deepwater integrated MPD riser joint, BTR RCD and sealed rotating systems; it also incorporated software and systems equipped with the EKD feature.

By incorporating a software and systems team, paired with the operator’s drilling engineers, a strategy was developed to lower mud weight (MW) and equivalent circulating density (ECD) by reducing surface backpressure (SBP) in reaction to fluid losses at shallow depths. It also identified the existence of sands with a manageable formation pressure, which could have jeopardized the plan to reach target depth (TD) in a single run and with only one casing string. During the static period, additional SBP was used to maintain a constant bottomhole pressure at the bit depth.

With the integrated MPD solution in place, the operator started with a lower MW and ECD, maintaining the ability to adjust SBP in response to changing conditions, such as fluid loss or kicks, while ensuring constant bottomhole pressure during drill pipe connections.

The MPD solution enhanced drilling efficiency by improving drilling speed, extending tool life, mitigating pressure-related issues and reducing the rig’s footprint. The operator drilled the interval in one run using only one casing string and with no fluid losses.

The MPD drilling strategy avoided the use of lost-circulation materials, eliminated an 11 7/8-in. liner, increased average daily footage by 167% compared with offset wells, and cut more than 14 rig days. It also saved $6 million in well construction costs compared with offset wells. Further, it enabled a 58% reduction in rig time and prevented the generation of 1,688 metric tons of CO2-equivalent emissions.

MPD application in top-hole sections

Uncertainties often arise when deciding whether to use MPD in the top-hole section. While the geomechanics window may allow for accommodating the ECD and equivalent static density, the cutting load effect must not be overlooked as it can be significantly high.

This effect can result in a range of 0.2 to 0.4 ppg, representing a pressure difference of 100 to 250 psi with the well clean and fully loaded.

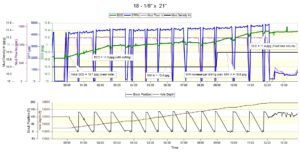

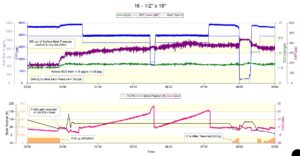

Figure 1 shows results from a separate case study in the Gulf of Mexico where MPD was not used. As a result, there was a positive increase of 0.3 ppg ECD increment when drilling as cutting load started.

MW was then increased in preparation for the predicted pore pressure at TD, aiming for a statically overbalanced mud. ECD continued increasing by an additional 0.4 ppg, and the well failed to hold the total ECD generated, leading to fluid loss.

In this example, MPD could have been beneficial to deal with high-cutting loading to maintain a smooth ECD along the drilling plan without compromising rates of penetration. In addition, before any MW changes, with MPD it is possible to simulate the predicted ECD in advance. In this manner, better decisions can be made. An example of this is the DFIT, which helps to determine the operational window limit.

Another important aspect to consider is planning proper MPD engineering. This is crucial for successful operations as a correct MW needs to be selected to maintain a constant ECD.

This design is necessary to accommodate an optimal SBP when no cutting load is in the well. It should also allow flexibility to reduce the SBP when drilling with full parameters and when higher cutting load is experienced while maintaining the desired ECD.

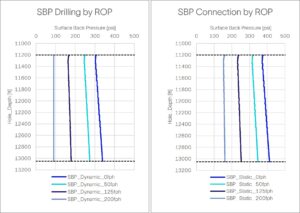

Figure 2 represents a hydraulic simulation designed to predict the necessary SBP while drilling and during connections for a given MW, flow rate, RPM and maintaining the target ECD for different rates of penetration.

Figure 2 represents a hydraulic simulation designed to predict the necessary SBP while drilling and during connections for a given MW, flow rate, RPM and maintaining the target ECD for different rates of penetration.

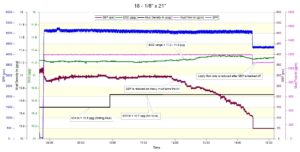

Another important consideration is fluid displacement. Figure 3 shows how MPD contributes to managing a constant bottomhole pressure during a fluid displacement for heavy mud. At some point, every MPD operation needs to be balanced with a higher MW to be able to open the well and recover the bottomhole assembly to the surface and then run the casing string or continue with other planned operations.

Where MPD was in place, the circulation started holding SBP, which was automatically reduced by the MPD control system to keep the ECD set point constant as the heavy mud entered the annulus.

As a result, the MW was increased by a positive 0.2 ppg and the ECD increment was only a positive 0.1 ppg, achieved through the correct utilization of backpressure. Finally, the well was displaced with no fluid losses.

Enhanced influx management

Well integrity stands out as a major risk in drilling activities. MPD offers the capability to promptly detect and control kicks in small volumes, allowing for circulation through the MPD equipment without the need to shut in the well with a subsea blowout preventer.

The efficiency of performing influx circulation up to the surface with MPD significantly reduces the time required, as opposed to conventional well control methods that may take days. With MPD technologies, this process can be accomplished in just a few hours, eliminating the need to increase the MW immediately. If necessary, MW adjustments can be made afterward while drilling.

Furthermore, MPD’s influx management reduces the risk of losses since there is no requirement to circulate through the well control choke line. The choke line’s small internal diameter can lead to excessive pressure on the well during circulation, making MPD a safer alternative by mitigating such limitations.

Figure 4 shows a real case where the equivalent volume (EQV) from the incorporated software and systems successfully detected and controlled a high-pressure kick of 4 bbl. This efficient response enabled the resumption of drilling after a 5-hr interruption for circulating the kick out of the hole.

This example is one of many, proving the effectiveness of MPD in detecting and controlling kicks in drilling operations.

East Mediterranean project

In a recent deepwater project in the Mediterranean, a customer employed the use of a formation pressure while drilling (FPWD) tool as a solution to reduce pressure uncertainty and associated complications and risks.

The customer initially expressed a preference for using FPWD over an MPD DPPT due to the superior accuracy in reading a specific formation’s pressure. But following SLB’s recommendation, the customer agreed to perform a DPPT to evaluate the open-hole pressure profile.

The first DPPT reduced ECD by 0.15 ppg. Observations from the DPPT identified the well as ballooning. Thus, the plan forward was to alleviate bottomhole pressure. This was done initially by reducing MW by 0.3 ppg, and after performing an additional DPPT, the ECD was reduced by 0.4 ppg.

The well was drilled to TD without losses or influxes. The subsurface team was able to use the FPWD for pressure readings in permeable formations, while MPD DPPTs allowed the subsurface team to validate their pore pressure predictions across the low-permeability formations present in the section.

As a result, an 11 3/4-in. contingency liner was avoided, while the reduced MW allowed casing to be run and cemented without losses. This could not have been achieved if conventional drilling had been used, or if DPPT had not been conducted.

As MPD technologies continue to develop, they will increasingly become an important contributor to efficient and profitable drilling operations. DC

@balance Control is a mark of M-I LLC, an SLB company.